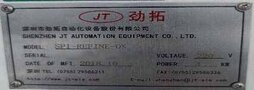

Used SHENZHEN / JT AUTOMATION SPI-REFINE-DX #293647101 for sale

URL successfully copied!

Tap to zoom

SHENZHEN / JT AUTOMATION SPI-REFINE-DX is a pc board assembly and manufacturing equipment designed to reduce cost and maximize quality. It comes in two versions: a standard version which can process up to four boards in parallel and a high capacity version which can process up to six boards in parallel. The standard version includes a reflow oven, a profile and RAM ladder, four independent process nozzles, and a fully automated component mounter. The high capacity version includes all of the same features, with the addition of a higher component mounting speed and capacity. The reflow oven featured in SHENZHEN SPI-REFINE-DX is designed to provide consistent reflow results by utilizing a five-zone air flow and a high-sensitivity PID controller for precise temperature control. In addition, the oven features a programmable motion profile which makes creating complex patterns and variable force programs easy. The system also features an intuitive LCD touch screen display for easy programming and a variety of data collection features. The RAM ladder of JT AUTOMATION SPI-REFINE-DX is designed to provide accurate standoff testing of surface-mount devices. The ladder's design includes a high-precision camera unit and a five-point temperature compensation machine which enable precision readings. The tool also includes an adjustable ladder height, topboard monitoring, and area programmable parameter for the fine-tuning of the profile. The four independent process nozzles featured in SPI-REFINE-DX are designed to handle a wide range of loading and placement processes. The features include a pick-and-place pressure control asset which allows replicative and precise placements, an advanced nozzle design which prevents jams and particle retention, and an integrated auto nozzle cleaner for maintenance and preventive cleaning. The fully automated component mounter featured in SHENZHEN / JT AUTOMATION SPI-REFINE-DX enables the manufacturer to rapidly and efficiently place components on the board. The mounter is equipped with a high-resolution camera model and four independent process nozzles, enabling the equipment to accurately place high-density components and subassemblies. Additionally, the mounter has an automated component recognition system which allows the unit to accurately inspect the placement of each component. SHENZHEN SPI-REFINE-DX is an advanced PC board assembly and manufacturing machine which reduces production costs and increases quality performance. The tool includes a reflow oven, RAM ladder, four independent process nozzles, and a fully automated component mounter. With its intelligent design and precise software, the asset can efficiently manufacture a wide range of products quickly, accurately, and reliably.

There are no reviews yet