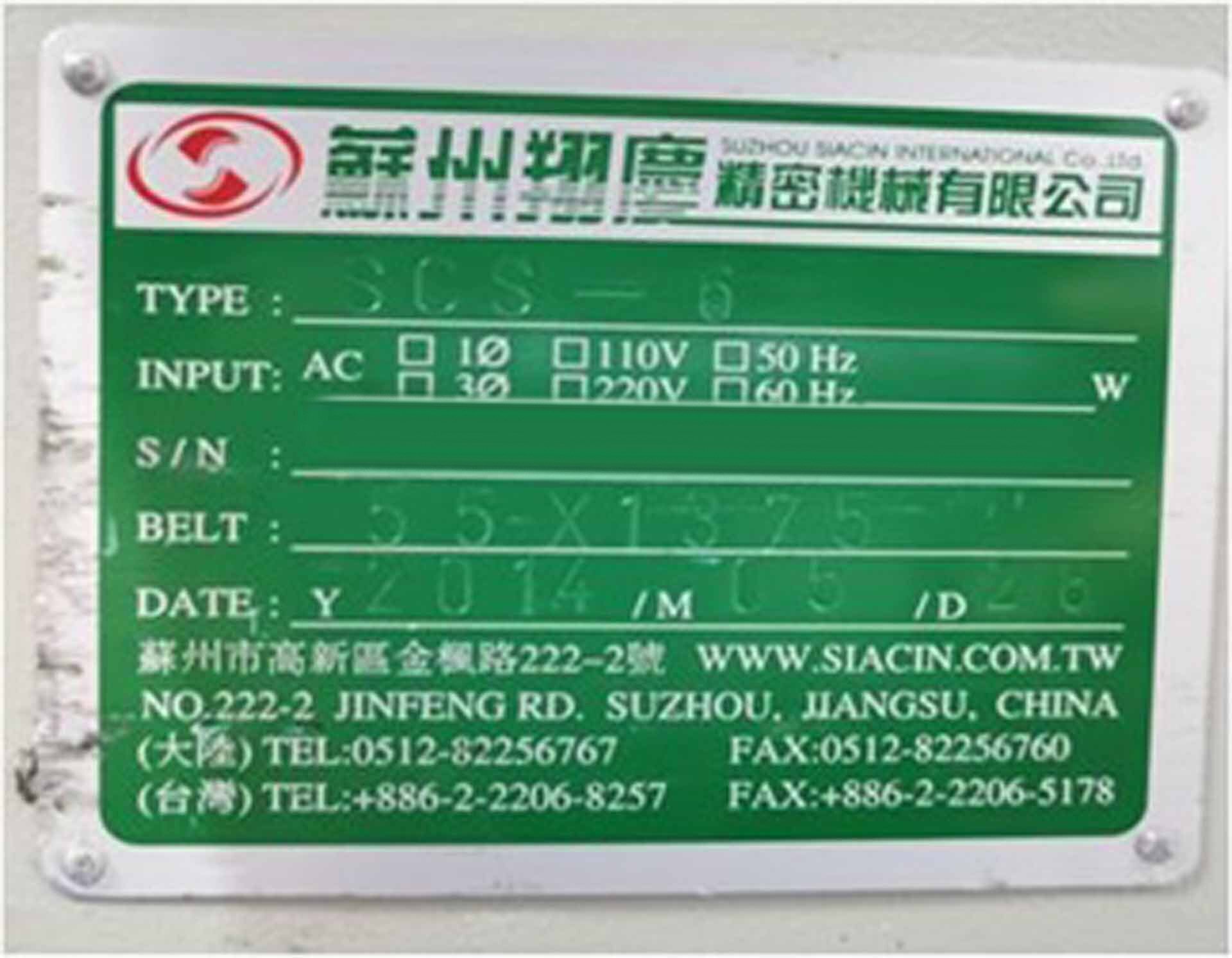

Used SIACIN INTERNATIONAL SCS-6 #9300418 for sale

URL successfully copied!

Tap to zoom

SIACIN INTERNATIONAL SCS-6 is a pc board assembly and manufacturing equipment designed to assist in the production of printed circuit boards (PCBs). It is a comprehensive system that includes components such as a materials handling unit, computer-controlled electrical component insertion machine, reflow soldering oven, direct imaging machine, testing equipment and vision inspection tool. The materials handing asset in SCS-6 provides automated conveyance of parts throughout the facility. This model is designed to ensure that parts are available on the surface mount assembly line when needed. It consists of a feeder equipment that can store multiple types of components and feed them onto the supplied surface mount machine. Additionally, an automated parts transfer unit transverses the assembly floor, and is capable of retrieving product from multiple areas and moving it to its required destination. The computer-controlled electrical component insertion machine is responsible for inserting electrical components onto the surface mount boards. The machine is programmed for precision when inserting components into the specific designated locations for each board. This machine can also identify parts and perform various operations on them such as soldering, testing, and verification of parts. The reflow soldering oven in SIACIN INTERNATIONAL SCS-6 is used in the process of soldering components onto the surface mount board. The oven heats the board to ensure the soldering process is complete and at the right temperature that is needed for the components to operate check. The reflow soldering oven also removes the solder from the boards, which is necessary for the board to function properly. The direct imaging system incorporates automated shape recognition with the ability to inspect, measure and detect solder paste and other solder related items such as flux. This unit captures images with a high-resolution camera and prints it onto the board. The direct imaging machine can also be used to inspect component placements, solders, and other aspects of PCBs. The testing equipment in SCS-6 performs testing operations such as in-circuit testing, functional testing, automatic optical inspection, and others. It can detect and alert staff of potential defects and or errors in a PCB. The vision inspection tool has the ability to inspect PCB's in real time. The asset can detect and alert of any electrical components which are not properly placed on the PCB design. This model ensures that the PCBs are up to manufacturing standards and are assemble accurately. Overall, SIACIN INTERNATIONAL SCS-6 is a comprehensive board assembly and manufacturing equipment designed for the production of printed circuit boards (PCBs). It includes components such as automated materials handling system, computer-controlled electrical component insertion machine, reflow soldering oven, direct imaging unit, testing equipment and vision inspection machine to ensure that the board is functioning correctly and up to industry standards.

There are no reviews yet