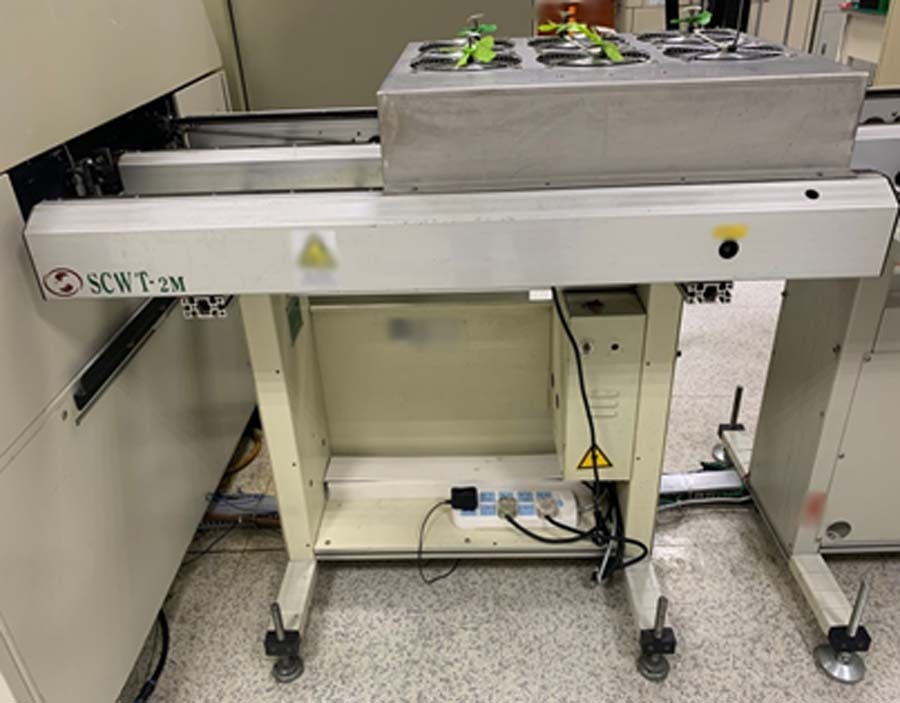

Used SIACIN INTERNATIONAL SCWT-2M #9363978 for sale

URL successfully copied!

Tap to zoom

SIACIN INTERNATIONAL SCWT-2M is a comprehensive electrical-connectivity hardware and component packaging equipment designed to aid in the assembly and manufacturing of printed circuit boards (PCB). SCWT-2M system utilizes a combination of automated test and placement systems to accurately manufacture PCBs in high volume and eliminate potential issues arising from human involvement. The most important component of SIACIN INTERNATIONAL SCWT-2M unit is the WAT process, a set of tools used to automate the placement of components onto printed circuit boards (PCBs). This makes use of 3D vision and computer vision-based systems to pick up components from a placement feeder, inspect them for any defects, and deposit them accurately into the printed circuit board. The integrated end-of-line tester ensures that all boards meet the required functional specifications before they can be shipped for further assembly. This tester verifies all electrical connections and evaluates the functionality of the various circuit elements. In addition, the tester can identify potential fault conditions by detecting electrical signals that are out-of-specification. The tester passes a signal to the automated handler which can automatically place a failed board into a reject bin or onto a rework pallet. SCWT-2M machine can accommodate various types of components and connectors, including through-hole and surface-mount components. Through-hole components require manual placement into the board, while surface-mount components can be automatically placed using the WAT process. The tool also incorporates a flexible selection of component placement and pick-and-place-tools depending on the type and complexity of components. SIACIN INTERNATIONAL SCWT-2M asset also offers a range of software solutions to track the progress of the assembly process. This includes a powerful programmable logic controller (PLC) which assists with automated data acquisition, flow control and monitoring. It can also be connected to a programmable interface (PIF) for the management of production data and external data tracking. SCWT-2M model has a range of features designed to optimize production capacity and speed. Its optical identification of components and automated pick-and-place process significantly reduce production time and costs while ensuring high-quality test and assembly. The integrated tester ensures that only functional boards are produced. Finally, the equipment's software capabilities allows for increased automation of production data and tracking.

There are no reviews yet