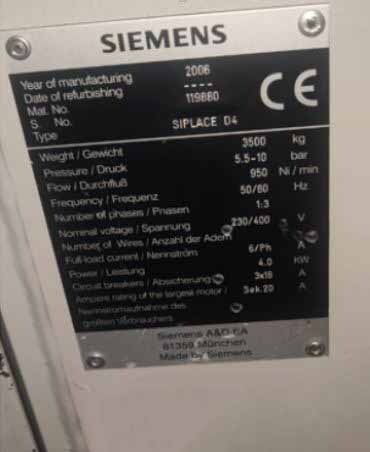

Used SIEMENS / ASM Siplace D4 #293644459 for sale

URL successfully copied!

Tap to zoom

ID: 293644459

Vintage: 2006

Pick and place machine

(4) DLM3 (RV12)

(4) COT

No feeders

2006 vintage.

SIEMENS / ASM Siplace D4 is a PC board assembly and manufacturing equipment, designed for manufacturing of both low-volume and large-scale electronics. ASM Siplace D4 system is a digitally controlled optical inspection machine, designed to provide reliable, accurate, and efficient production of printed circuit boards. SIEMENS Siplace D4 incorporates a variety of features to ensure effective production and reliable results. Siplace D4 unit is comprised of two main components: the primary station and the secondary station. The primary station includes a conveyor belt that drives printed circuit boards through the machine, while the secondary station is the main processing center. At the primary station, the boards are loaded, oriented, and inspected for defects. The tool then moves the boards through the secondary station, where an automated pick-and-place asset is used to load components onto the boards. Following component placement, the boards are lightly press-fitted to hold components securely in place. Once the components have been secured, the boards are subjected to a visual inspection to ensure accuracy, before being placed on the heated plate for soldering. Throughout the entire process, a variety of sensors are used to detect and log errors, alerting the operator if a board should require attention. SIEMENS / ASM Siplace D4 model also features advanced programming and monitoring capabilities. An advanced programming language is used to set and monitor parameters, enabling users to make adjustments as needed to ensure optimal product performance. The machine is equipped with a range of connectivity options, allowing user to communicate with the machine and remote hosts, and share data with other systems. This makes it possible to customize the equipment and maximize throughput or process specific jobs. ASM Siplace D4 system is widely used in the electronics industry due to its flexibility, accuracy and efficiency. Built with advanced features to optimize production, the machine ensures consistently reliable results and provides a safe working environment for operators. With excellent programming capabilities, it is possible to customize the unit for specific job requirements.

There are no reviews yet