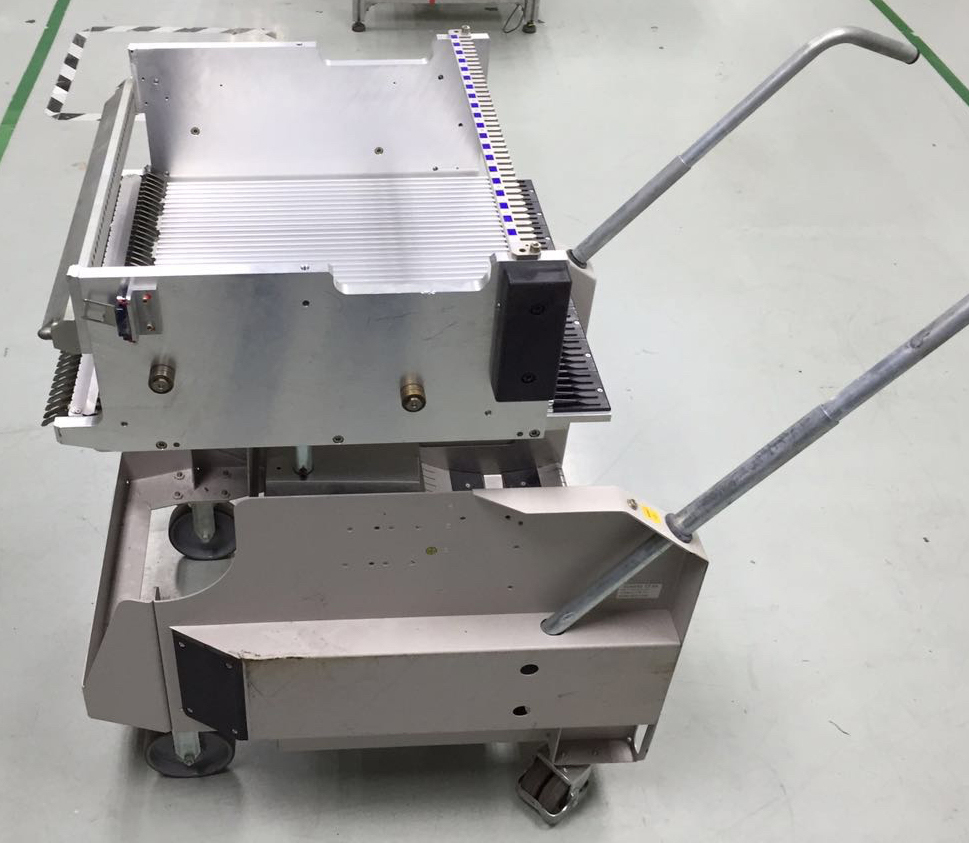

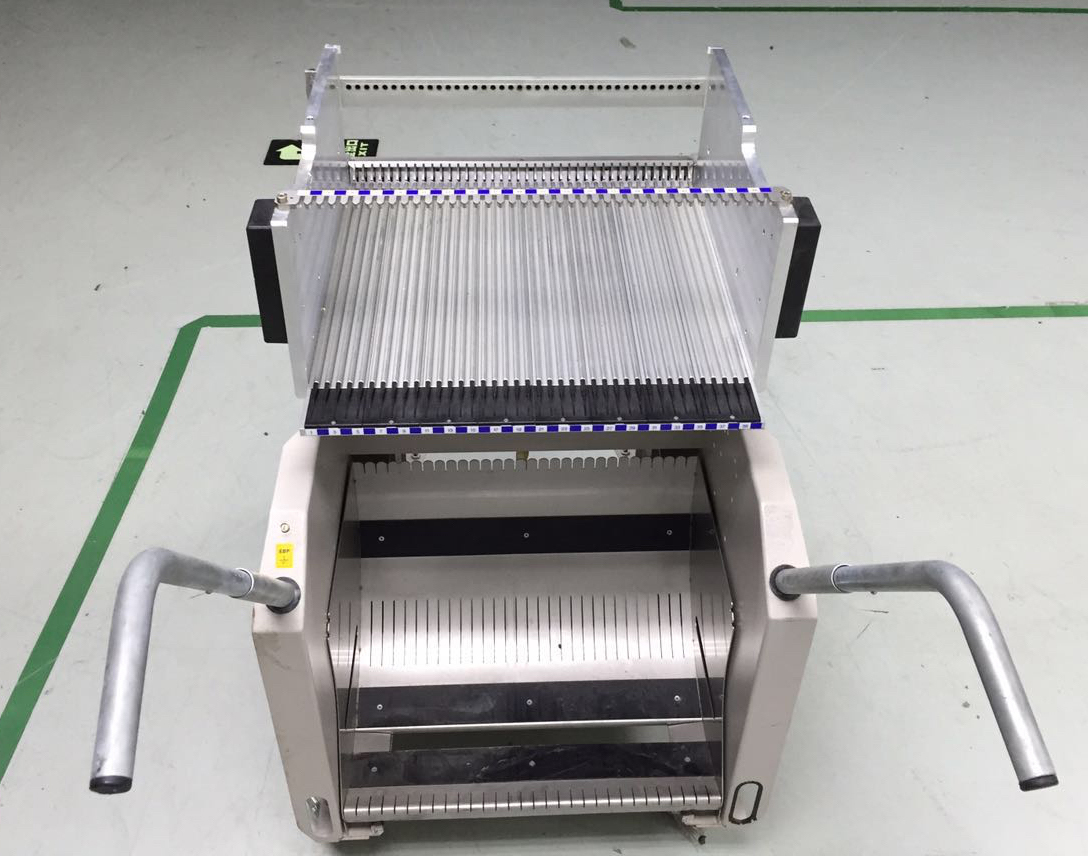

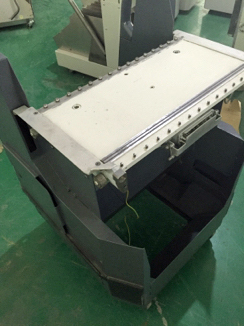

Used SIEMENS HF / HS / X4 #9040685 for sale

URL successfully copied!

Tap to zoom

The Siemen SIEMENS HF / HS / X4 is a series of automated PC board assembly and manufacturing systems designed to provide customers with a more streamlined, efficient and cost-effective production experience. HF, HS, and X4 systems are tailored to processes outside the standard parameter of PCB assembly line production. This includes processes such as manual component placement, deep plating, wave soldering, intricate stenciling and even edge connector soldering. The X4 series features multiple production lines and can be tailored to the customer's needs. Each line includes product-specific machines, such as automatic pick-and-place systems, ovens, and reflow systems; semi-annual and manual assembly workstations; as well as multiple test and inspection technologies. The X4 series is built on the company's standard 'flexible production line' platform, which is tailored specifically for the customer's requirements; including a combination of traditional and modern machines. The machine can be connected to the customer's Product Data and Warehouse Management System (PDWMS) to provide real-time production monitoring and control. The Siemen HF / HS / X4 system is designed with multiple quality control functions, such as automatic cleaning, temperature control, humidity control, pressure control, flux regulation, pre- and post-reflux tests, as well as in-line test analysis. It also incorporates features such as in-line validation to test the assembly against pre-defined parameters, as well as traceability of all components used in the assembly process. In addition, the X4 series offers advanced factory automation, providing a high level of flexibility to enable easy production reconfiguration and scaling across various process stages. This can be combined with additional components such as an Intelligent Lighting system, further increasing the production line's efficiency. Finally, the X4 series provides sophisticated process monitoring and analysis to provide information on production processes, enabling customers to effectively monitor progress throughout the entire production cycle. Automated yield rate monitoring and traceability of all components used in the assembly process can further enhance quality control.

There are no reviews yet