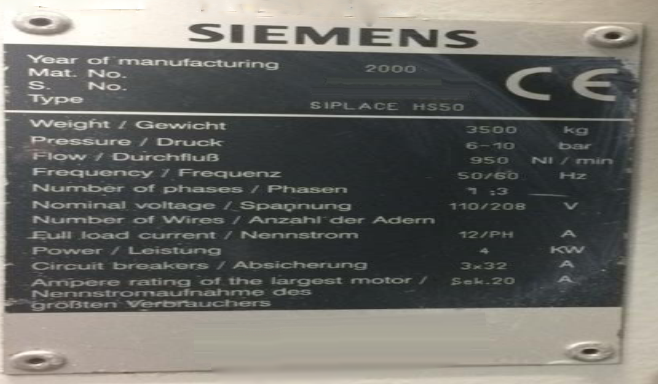

Used SIEMENS HS50 #9192040 for sale

URL successfully copied!

Tap to zoom

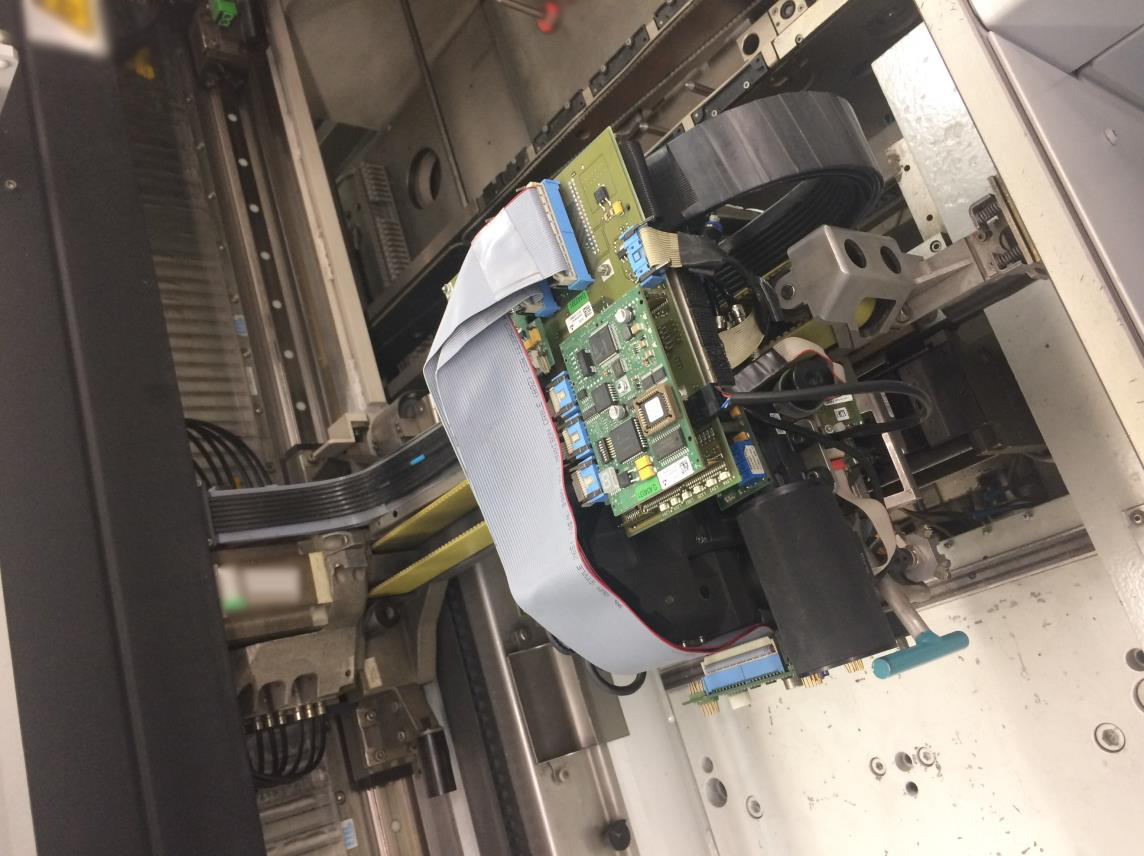

SIEMENS HS50 PC Board Assembly and Manufacturing Equipment is an innovative system that allows for improved efficiency in manufacturing components for various PCB assemblies. It is suitable to build anything from the simplest circuit boards to the most complex multilayer boards. This unit includes a range of components from which the user can choose from depending upon their needs, and they can then configure the machine to their specific needs. The SiemenSIEMENS HS 50 tool includes several functions and features aimed at optimizing the possible output quality and making the process easier and faster. The asset includes an automated placement function, for placing components precisely and efficiently on the board, and also a placement built-in verification process, to check that components are correctly placed. The placement machine is driven by a SIEMENS industrial PC, for communicating with the control software and the automated placement motors, and allows for a fast adjustable process speeds to allow for greater output. The model also makes use of a wide range of feeder technologies allowing for complex component feeding without sacrificing precision and accuracy. It makes use of various types of linear and belts feeder systems, and a magnetic feeder option, to ensure that components are placed in the specific locations. The SiemenHS-50 equipment also includes other features such as pick-and-place inspection technology, for better detection of errors such as missing parts. The system is also equipped with an integrated vision unit capable of scanning components to detect any chip placements and measurements errors. Finally, the SiemenHS 50 PC Board Assembly and Manufacturing Machine is equipped with a 3D inspection tool, which is a high resolution camera that can be used to visually inspect components before, during, and after placement. The SiemenSIEMENS HS-50 PC Board Assembly and Manufacturing Asset is an impressive device offering the user a wide range of functions and features to ensure maximum efficiency and quality in the manufacturing of PCBs. With its high technological features, the model is an excellent choice for companies requiring a reliable and efficient solution for their components production.

There are no reviews yet