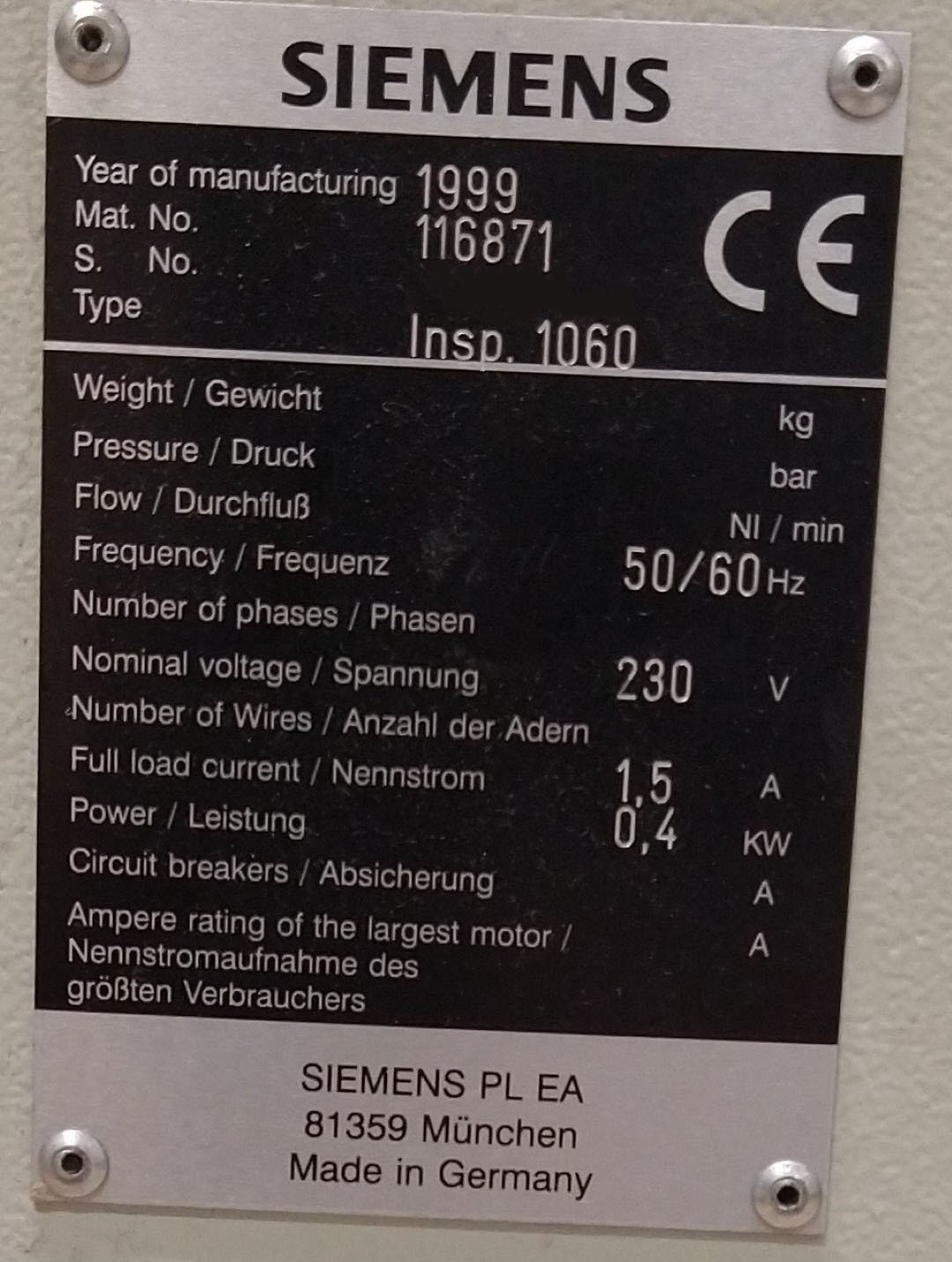

Used SIEMENS Inspe 1060 #293585605 for sale

URL successfully copied!

Tap to zoom

SIEMENS Inspe 1060 is a fully automated pc board assembly and manufacturing equipment. The system is designed to reduce production times, improve production accuracy and increase yield. It helps reduce set-up, making change-over times quick and easy. All components including PCBs and housed assemblies are loaded into Inspe 1060 and they are assembled automatically to create the completed product. SIEMENS Inspe 1060 is designed to process up to 1060 individual pc boards per hour, with no limit on the number of boards per assembly job. The unit is capable of mounting, feeding, inspection and testing components across multiple pc boards, as well as a variety of materials such as FR1 and FR4, FR4-II, CEM-I, CEM-II and CEM-III. It also uses advanced laser, vision and microscopy technologies to carry out product inspection with high accuracy. Inspe 1060 machine is based on a modular design, enabling customized configurations. It is designed to be both flexible and reliable, offering fast and accurate production processes. The various components of the tool, which include a high-accuracy vision inspection asset, a 3D Video Measurement Model, a Laser Process Mapping Equipment, and a Component Placement System, are all connected to the main control panel. This allows for easy monitoring of the entire production process, ensuring that the finished product is of high quality. SIEMENS Inspe 1060 unit is a highly reliable and efficient pc board assembly and manufacturing solution. It provides low cost of ownership and low maintenance costs, and offers a wide range of options for customization. Its modular design makes it easy to upgrade, ensuring that it is always up-to-date with the latest advancements in pc board assembly and manufacturing technologies. All in all, Inspe 1060 is the ideal pc board assembly and manufacturing machine for any modern business.

There are no reviews yet