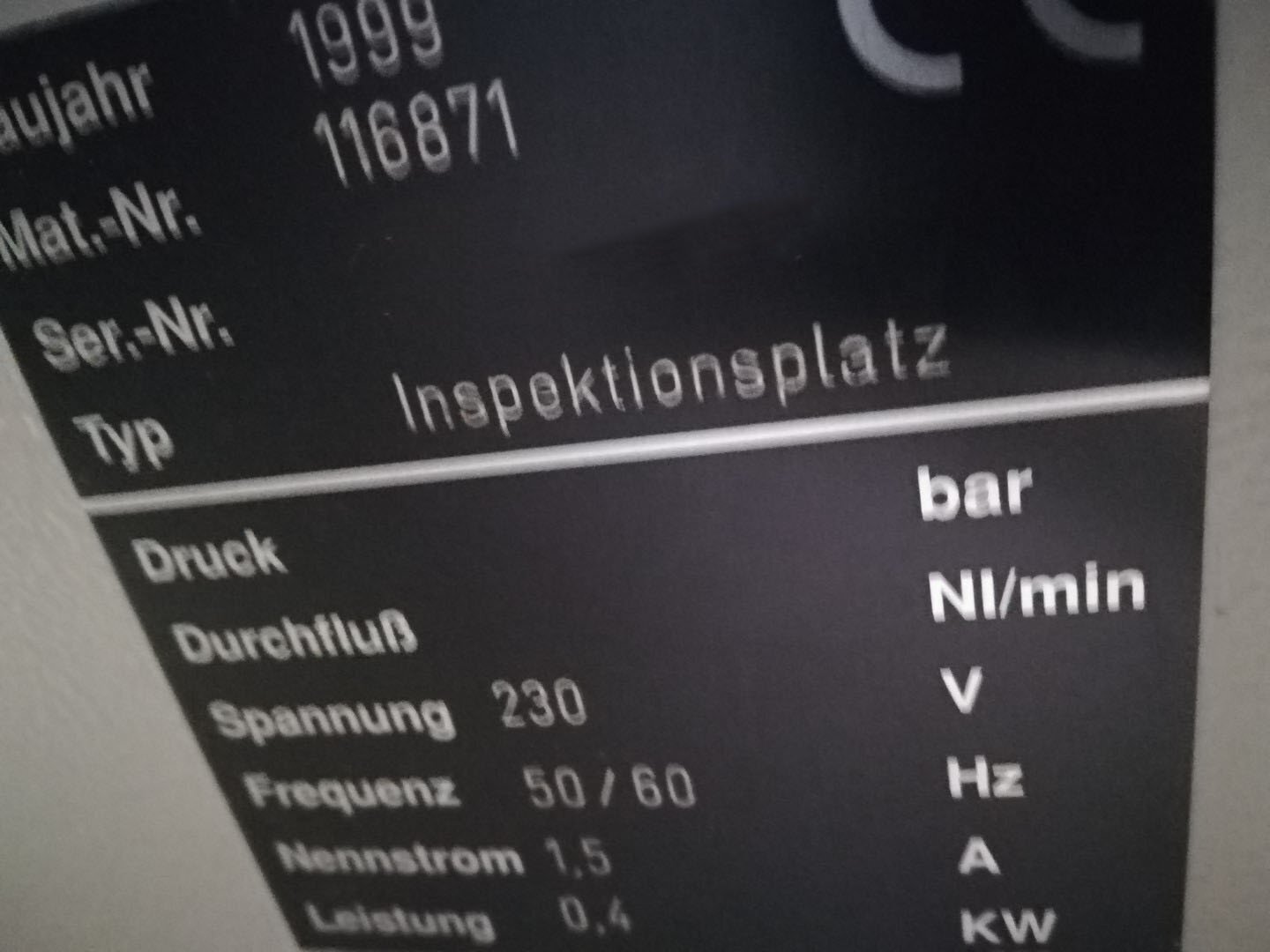

Used SIEMENS Inspektionsplatz #293585951 for sale

URL successfully copied!

Tap to zoom

SIEMENS Inspektionsplatz is a PC board assembly and manufacturing equipment that automates and simplifies the production of electronics components. This system is designed to quickly and efficiently build high-quality electronics with pinpoint accuracy and precision. Inspektionsplatz is equipped with several automated processes including single-axis rotation for accurate imaging and alignment of components, programmable heat-sink placement for heat dissipation, and a 5-axis vision unit for precise parts placement. With this level of automation, the machine can produce components with a high level of quality assurance. The tool also supports multiple PCB sizes and custom connector placement to meet design requirements. It is able to handle multiple types of connectors, allowing the use of various types of components. SIEMENS Inspektionsplatz utilizes a combination of vision asset, motion control, and robot systems in order to accurately place and inspect components. It is equipped with a control model that is able to detect any errors before the completion of the manufacturing process. The equipment can identify and record the components that are used in each manufacturing operation and also check to confirm that the correct number of components have been assembled. The system is also designed to reduce waste and provide a detailed report of the components used. Inspektionsplatz is easy to use and set up, allowing for quick set-up times. It is an effective solution for the production of precision components and for the efficient assembly of complex boards. The unit's automation allows for highly efficient and accurate production of PCB assemblies for a wide range of electronic applications.

There are no reviews yet