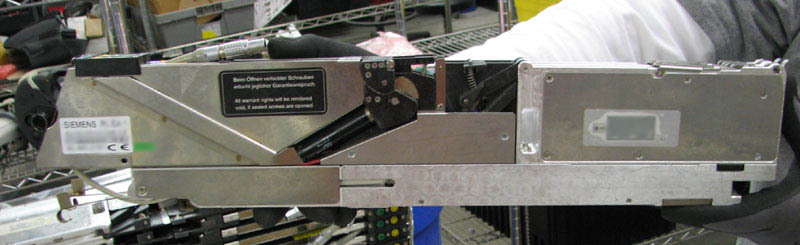

Used SIEMENS P/N 00141096-03 #140126 for sale

URL successfully copied!

Tap to zoom

SIEMENS P/N 00141096-03 is a pc board assembly and manufacturing equipment designed to reduce operator fatigue and tedious manual handling of components. This system provides quick, reliable and cost-effective electronic production through an automated and well-controlled process. The main feature of SIEMENS P/N 00141096-03 is its ability to rapidly and accurately place components onto PC boards. The unit uses motion controllers to ensure precise deposit of components and positional accuracy. It is able to assemble multiple component types on a single board, further increasing its efficiency. This can make several sequential operations, such as component placement and component testing, more efficient. In addition, the machine can also accommodate a wide range of component shapes and sizes. With its high resolution imaging capability, accurate component placement and inspection each is achievable. It also has the required automation to reduce the manual component handling, thus enabling higher productivity. Moreover, SIEMENS P/N 00141096-03 is equipped with pre-programmed process parameters as well as a graphical user interface. This allows the operator to easily configure the tool and its parameters according to the specific requirements of a job or task. This asset also features useful features, such as vision-guided recognition, real-time inspection, production tracing and statistical process control, which enables a higher degree of process reliability. The model also offers fully integrated transportation and handling solutions designed to increase the efficiency of its production. Its mechanics are designed to improve work-flow ergonomics, reduce downtime and ensure mechanical robustness. It is also equipped with a conveyor equipment to provide accurate and consistent movement of parts which is highly desired during a manufacturing process. In conclusion, SIEMENS P/N 00141096-03 is a pc board assembly and manufacturing system that can reduce operator fatigue and tedious manual handling of components, while achieving higher production speeds and higher production security. It is offers excellent options for efficient production, including motion controllers for precise component placement, automated component handling, a user-friendly graphical user interface, vision-guided recognition, real-time inspection and conveyor unit. This machine can increase the reliability of process and provide increased productivity in many production applications.

There are no reviews yet