Used SIEMENS Siplace 80 F3 #100090 for sale

URL successfully copied!

Tap to zoom

ID: 100090

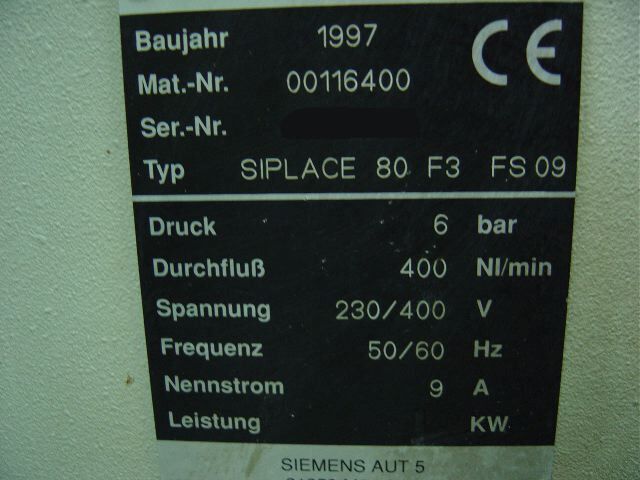

Vintage: 1997

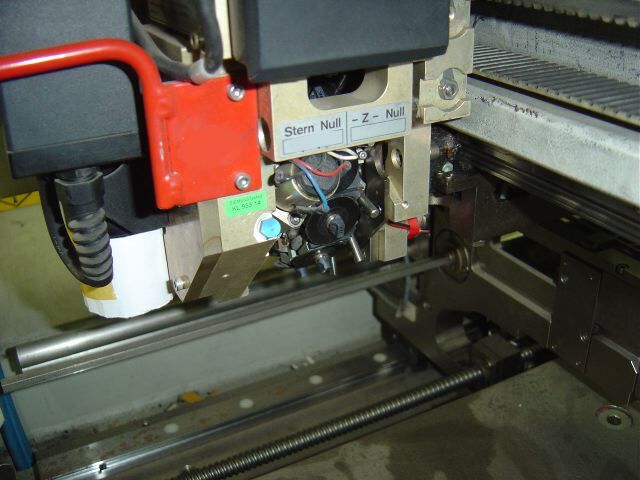

Placement system / SMD placer

Multi tray

(50) 2 x 8mm

(3) 12 / 16mm

(5) 24 / 32mm

1997 vintage.

SIEMENS Siplace 80 F3 is a highly advancedinline pc board assembly and manufacturing equipment that offers a complete solution for the assembly and testing of circuits. This system can provide high-speed placement of components with accuracy, tracing, and automation in order to complete projects quickly. The unit is equipped with an advanced robotic arm for precise, parallel circuit assembly and testing. This mechanical arm is capable of operating with a maximum acceleration speed of up to 15 m/s², a sample-effective movement speed of up to 15 m/s, and a peak rotation speed of up to 5,500 rpm. The sophisticated interface of Siplace 80 F3 allows for total machine integration, which enables the processing and storage of data, as well as access to existing databases. The tool also allows for quick product changeover with its advanced software and a variable placer head. Furthermore, due to its fast processing speed, the asset can place as many as 25,000 components per hour, depending on the type and size of the components. SIEMENS Siplace 80 F3 is designed to reduce the costs associated with the assembly and manufacturing of printed circuit boards, while maintaining a high level of quality and productivity. The model is equipped with a tried and tested image recognition and conveyor-fed placement technique, along with superior auto-route and autofocus algorithms, that provide high accuracy and reliability of components. In addition, Siplace 80 F3 can be connected with a high-speed 3D solder paste inspection machine and a high-performance placement machine and is capable of carrying out a maximum of 15,360 points in a single cycle. This advanced equipment also has the capability to integrate a variety of systems, including optical, AOI, and X-ray inspection machines. Overall, SIEMENS Siplace 80 F3 is a versatile, high-speed pc board assembly and manufacturing system, with advanced software and a robust robotic arm for precise, parallel circuit assembly and testing. Its quick product changeover and advanced image recognition and conveyor-fed placement technique make it an ideal solution for the needs of printed circuit board production and automation.

There are no reviews yet