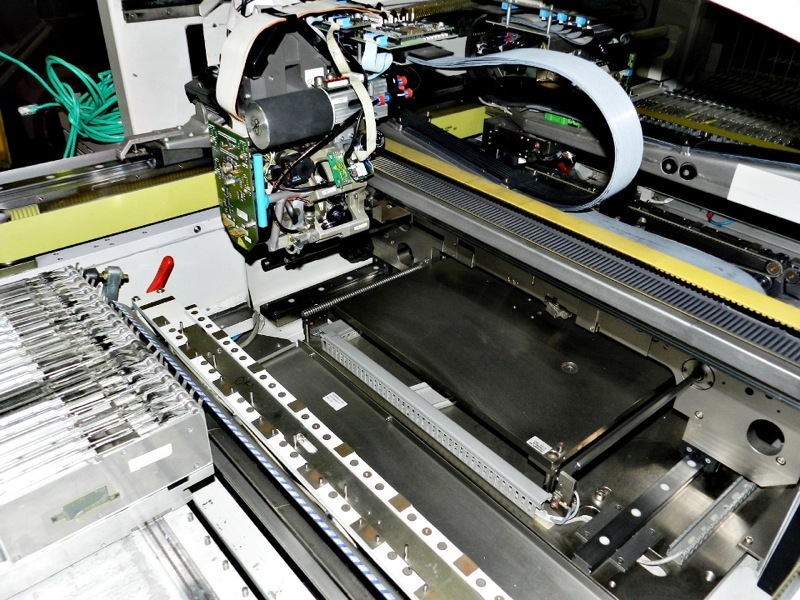

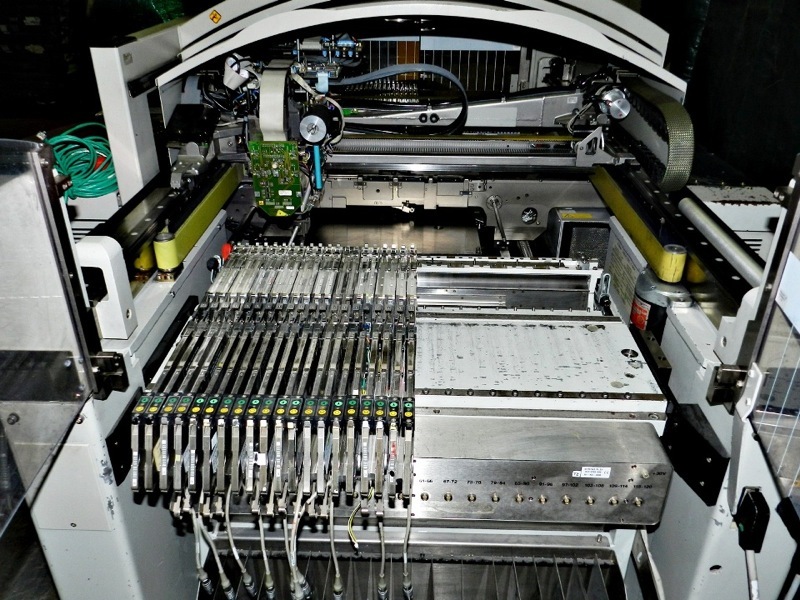

Used SIEMENS Siplace 80 S20 #176910 for sale

URL successfully copied!

Tap to zoom

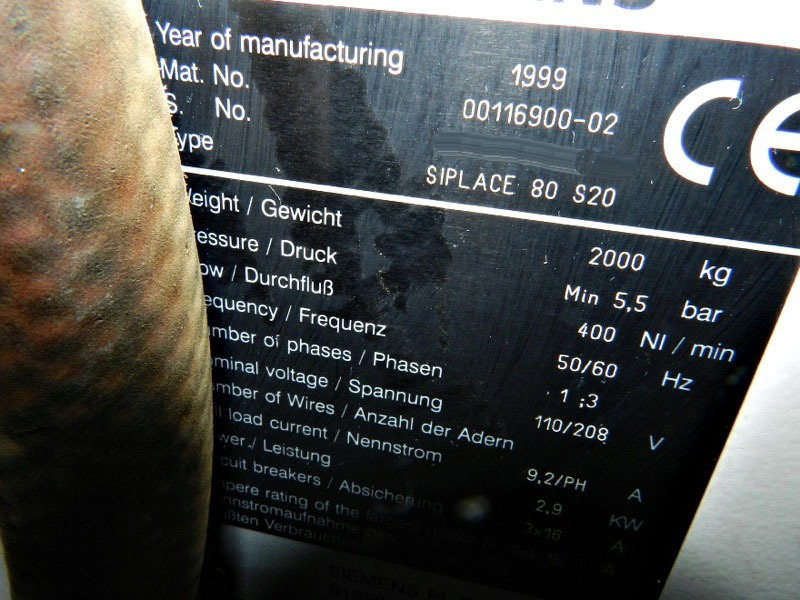

ID: 176910

Vintage: 1999

Surface Mount Placement Machine

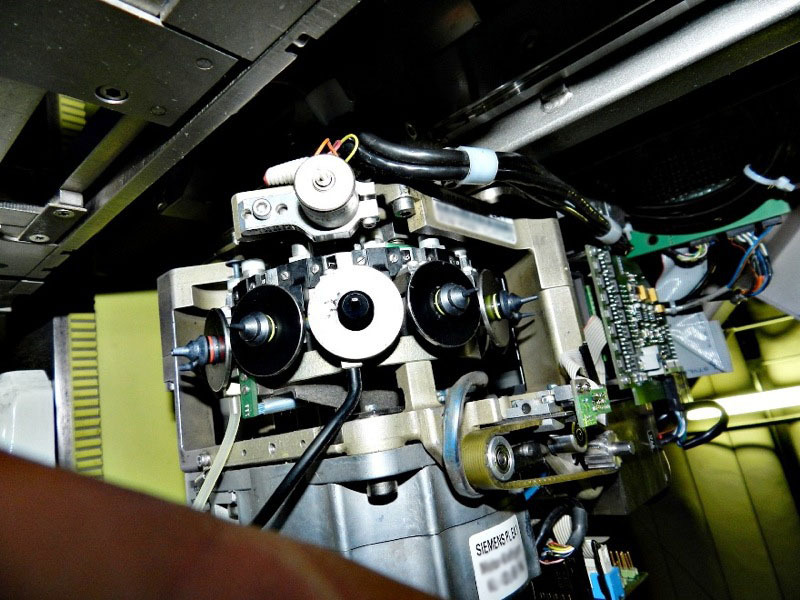

(2) Component cameras per head

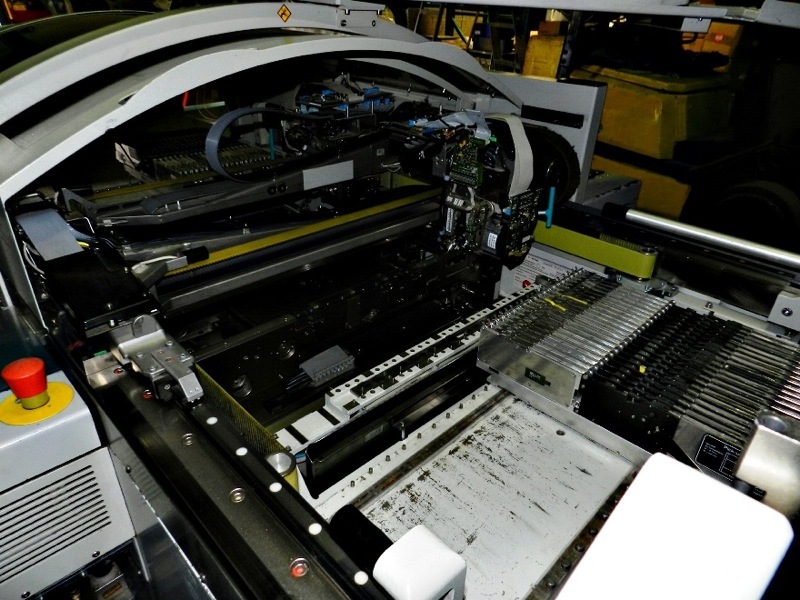

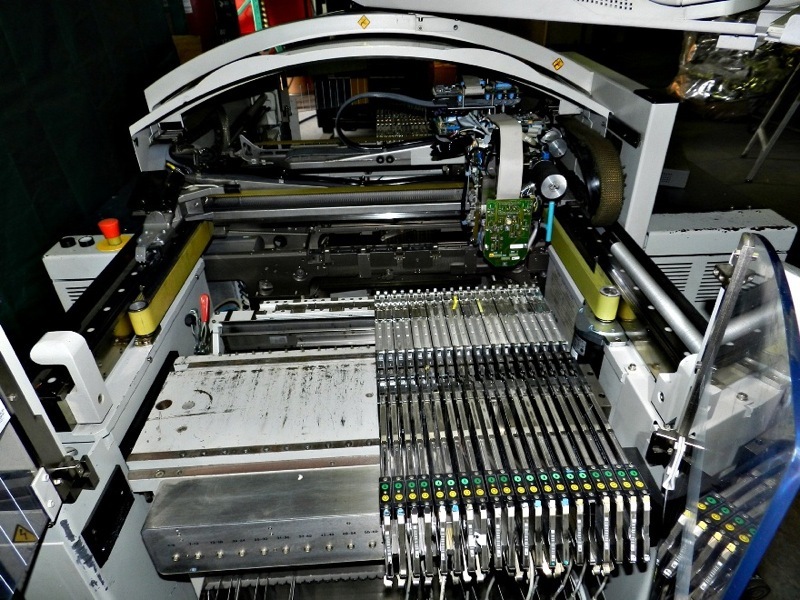

(2) Heads

(12) nozzle Revolver Head Standard

(1) Fiducial camera per head

(2) Feeder table

Board size Min / Max 50X50 mm to 460 x 216.5 Dual conveyor

50 X 50 mm to 460 x 460 mm Single conveyor

Component size Min / Max 0402 to 18.7 x 18.7 mm

Max. component height 6 mm

Max. component weight 2 gr

Placement force 2.4 - 5.0 N

Performance 10,000 cph

Min. pitch lead / bump 500 / 300 µm

Min. ball / bump diam. 200 µm

(20) 8x2 Feeders

Siplace SW Ver Siplace PRO 407.04

1999 vintage.

SIEMENS Siplace 80 S20 is a high-performance, cost-efficient pc board assembly and manufacturing equipment designed for industrial, small-scale production. Its core components are robust and reliable for dependable production in fastened, large and small batches. Siplace 80 S20 offers efficient, high-performance placement of both traditional and advanced components. Its Adaptive Placement System ensures smooth process and eliminates manual intervention during the SMT process. SIEMENS Siplace 80 S20 is the ideal solution for industrial, small-scale production, sized to fit a 200x200 mm panel size. This unit supports a wide range of components, including standard packages, microBGAs up to 0.4 mm pitch, fine pitch components up to 0.3 mm pitch, and micro-leadless components such as 0201 and 008004. With an impressive placement speed of 22,000 cph, the S20 can placed up to 5,890 standard components per hour (64 x 300 mm). For full traceability, Siplace 80 S20 includes a process monitor, which allows users to effortlessly work with multiple PCBs simultaneously, saving time, rather then having to manually set and reset boards. In addition, the user can monitor progress and identify any discrepancies quickly. For maximum uptime, the S20 si utilizes advanced nozzle health monitoring to continuously adjust tool parameters to ensure the highest quality standards with minimal scrap rates. The S20 also features a top-down camera module which seamlessly eliminates double sided placement and minimizes manual effort to solve placement issues on odd shaped boards. The S20 si also features advanced data input capabilities, including an intuitive user interface, and support for various board formats, as well as automated processes. Overall, SIEMENS Siplace 80 S20 is a highly reliable, cost efficient machine designed for fast, cost-effective, and high-quality SMT performance. The tool offers maximum uptime and ultimate control, making it the perfect choice for automated, small-scale production.

There are no reviews yet