Used SIEMENS Siplace 80 S20 #293666340 for sale

URL successfully copied!

Tap to zoom

ID: 293666340

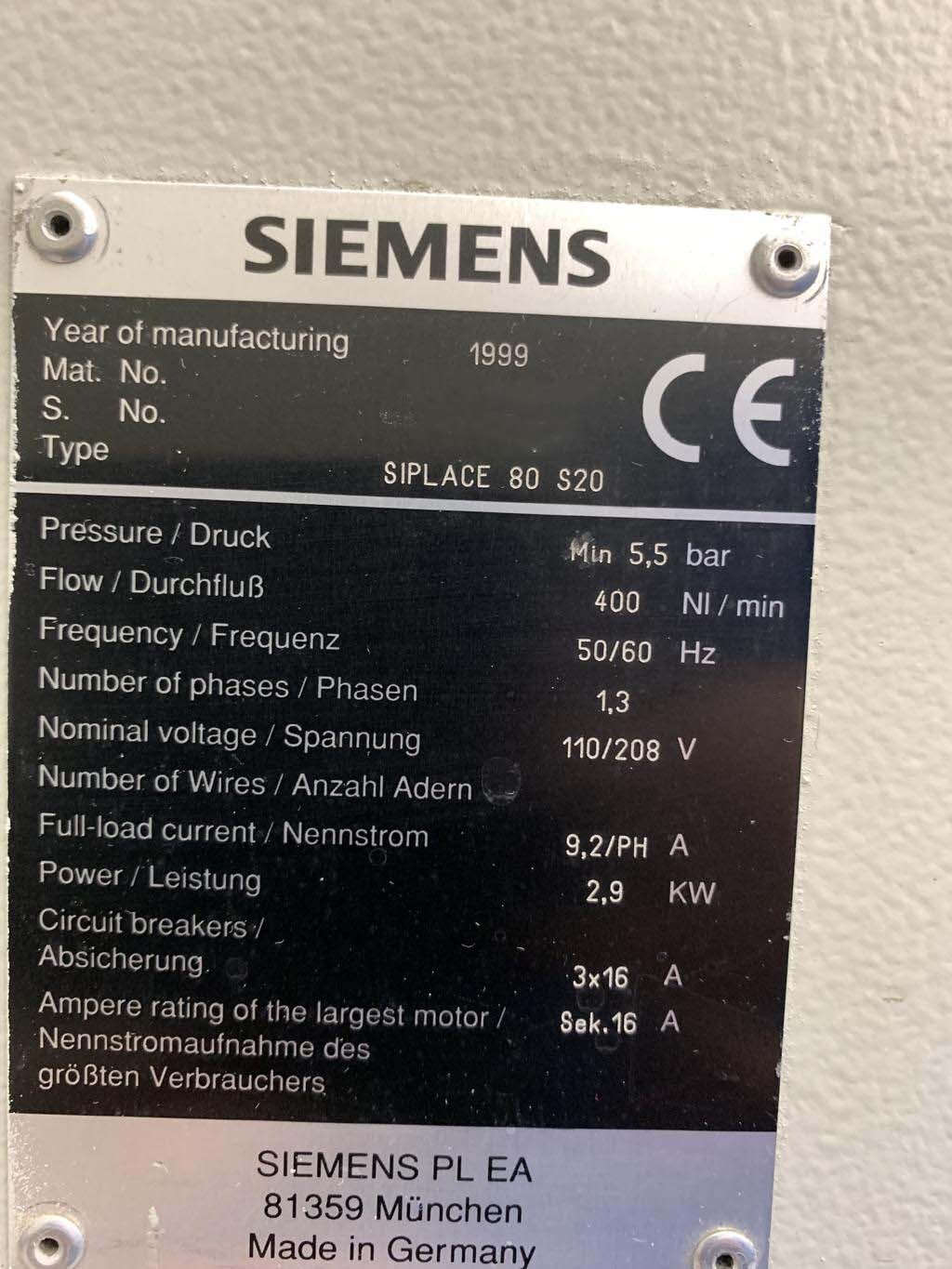

Vintage: 1999

Pick and place machine

Feeder table

PC Included

1999 vintage.

SIEMENS Siplace 80 S20 is a high-performance pc board assembly and manufacturing equipment. This system, when combined with an automated placement line, provides an economical and efficient solution for placing components on printed circuit boards. The unit includes a single-head double-gantry placement head and a high-accuracy vision machine that help guarantee precise placement accuracy on the board. It also offers an integrated media-capture functionality for component lead frames. The machine is designed around an innovative, fully programmable user-friendly design which allows for the placement of components of different shapes, sizes and orientations on both single-sided and double-sided boards. The SMEMA (Smooth Machine Envelop Monitoring Area) interfaces offered by Siplace 80 S20 provide a standard interface for connecting different components such as feeders and placement heads. The tool is designed for high throughput and comes with a standard speed of 40,000 placements per hour. It also has an optimized placement head that improves placement accuracy and speeds up the process. The asset also comes with several advanced features that enhance the quality and productivity of the assembly and manufacturing process. These include an adjustable placement head unit which allows for more precise alignment of the component leads. It also has an intuitive user interface and an integrated error detection and correction model that decreases assembly time and cost. SIEMENS Siplace 80 S20 can be used to place leaded and lead-free components, including surface mount technology components. The equipment is also compatible with various types of solder paste, flux, and other adhesives for automated dispensing and fluxing. The machine is compliant with ESD safety standards and ensures a safe and productive working environment. Overall, Siplace 80 S20 is a sophisticated pc board assembly and manufacturing system that offers an efficient and cost-effective solution for high-volume assembly and manufacturing. It is designed to reliably and accurately place components of different shapes, sizes, and orientations, and offers an intuitive user interface, flexible programming functions, and integrated error detection and correction systems. The unit is designed to meet industry safety standards and ensure a safe and productive working environment.

There are no reviews yet