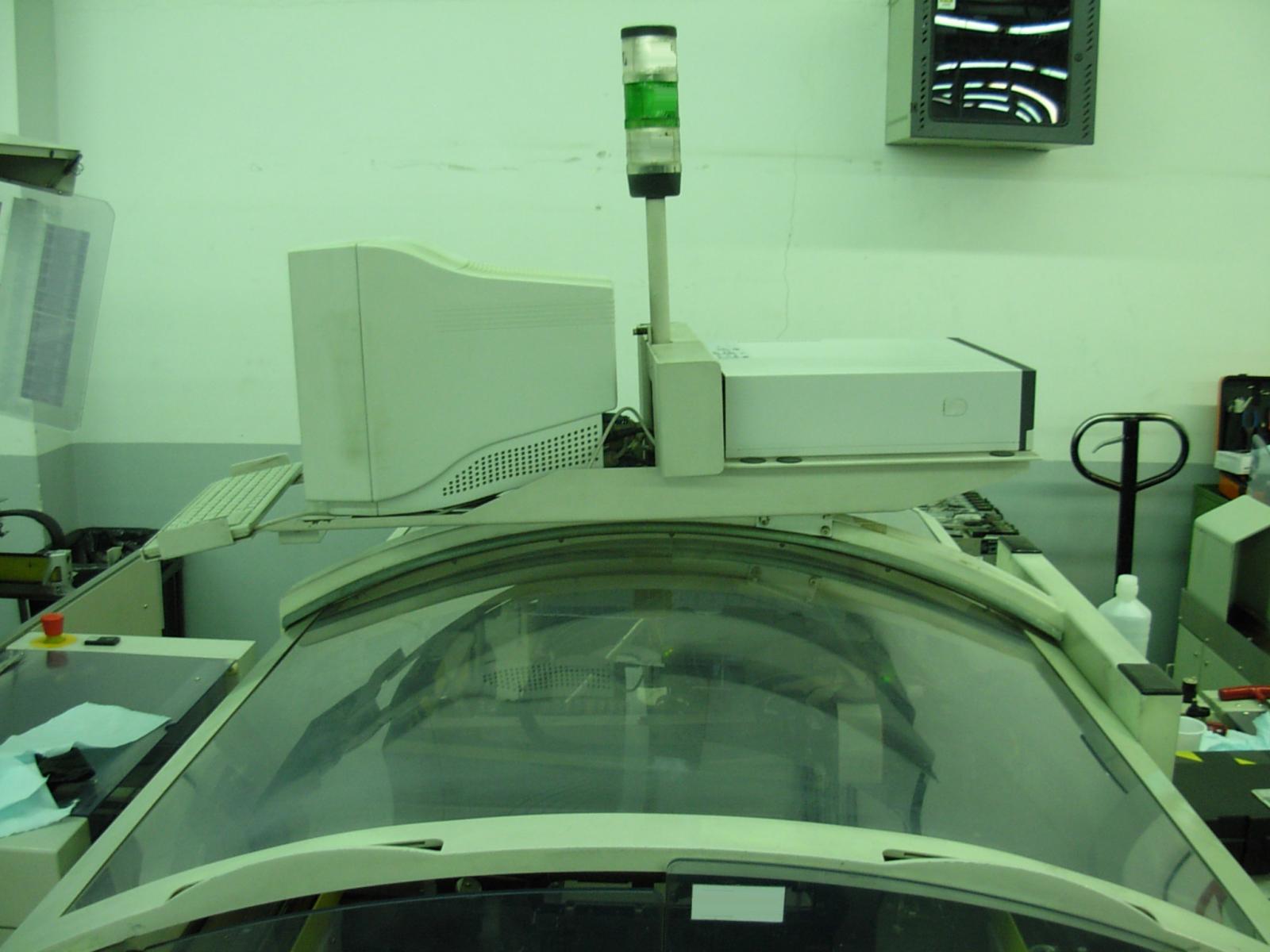

Used SIEMENS Siplace 80 S20 #9121135 for sale

URL successfully copied!

Tap to zoom

ID: 9121135

Surface mount placement machines

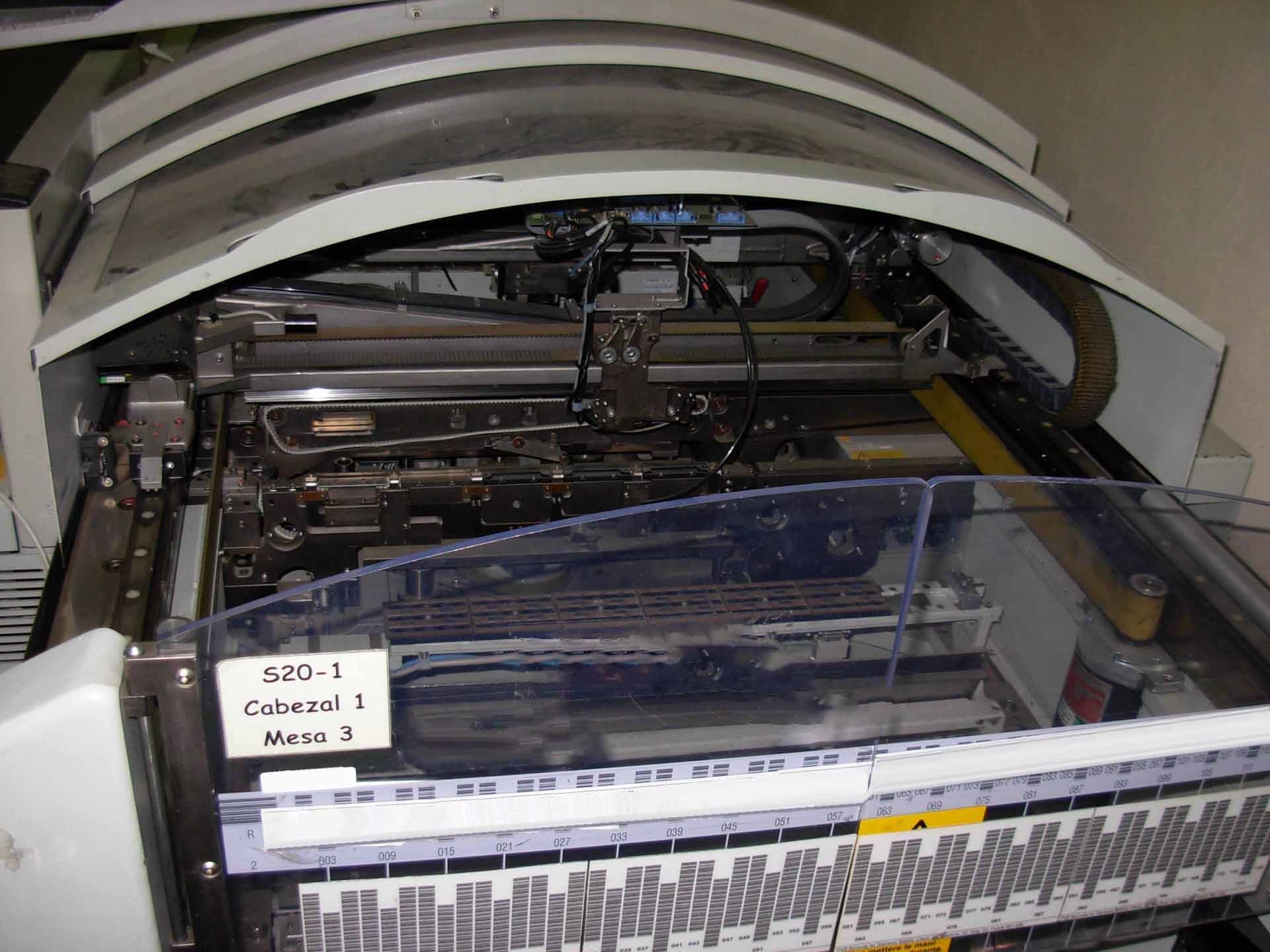

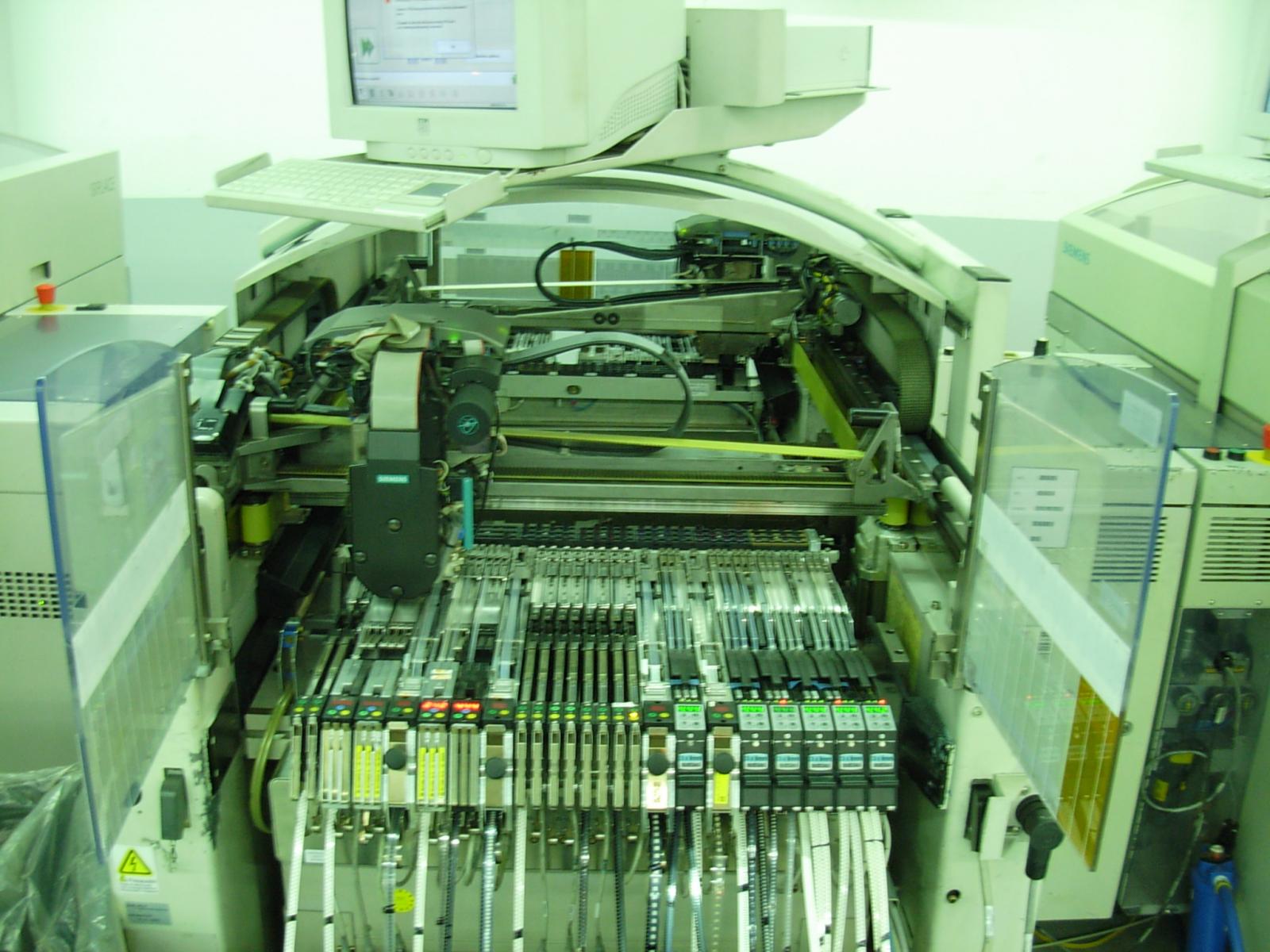

(70) Feeders with tables

Sample & double

Chipper.

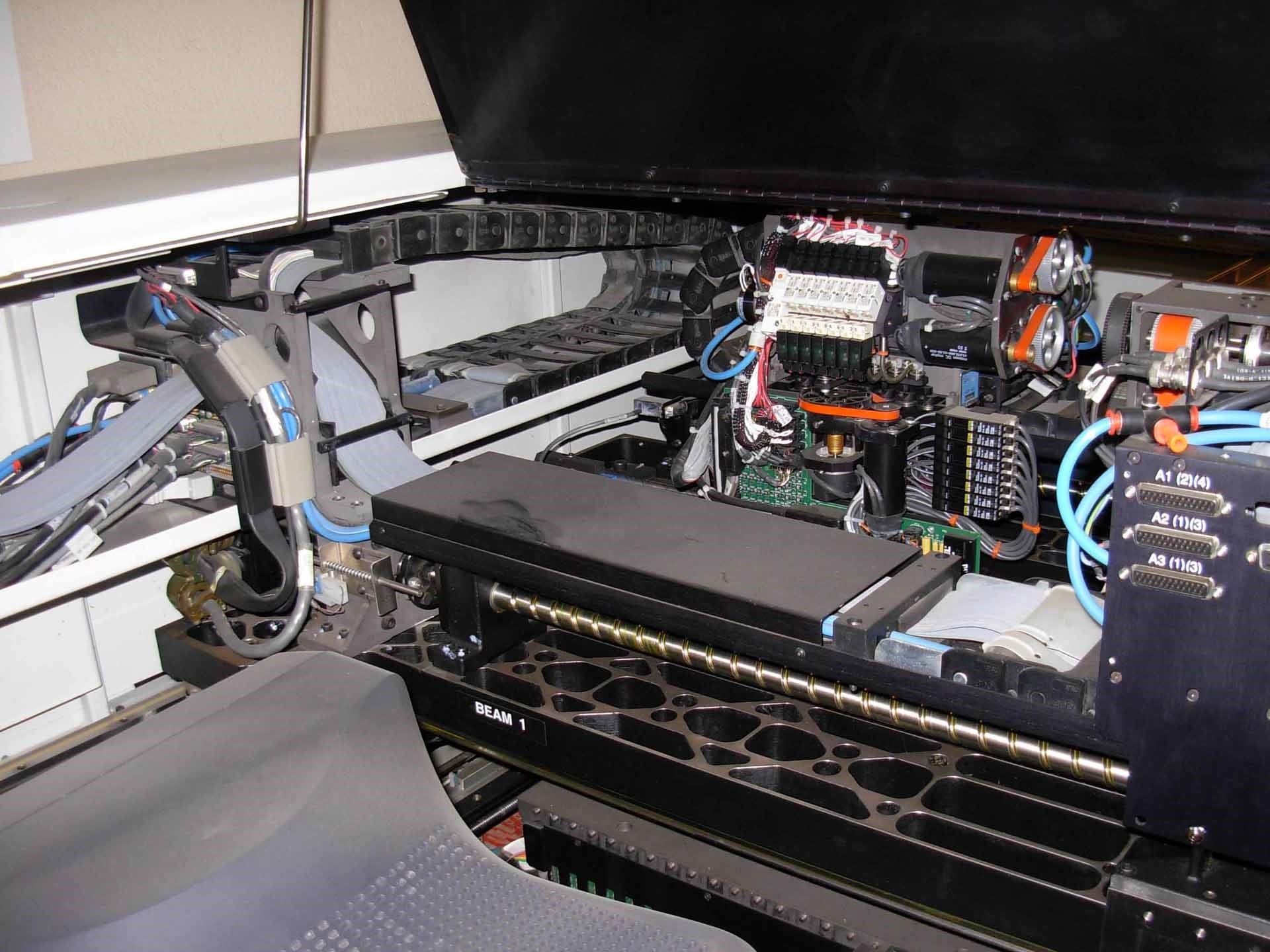

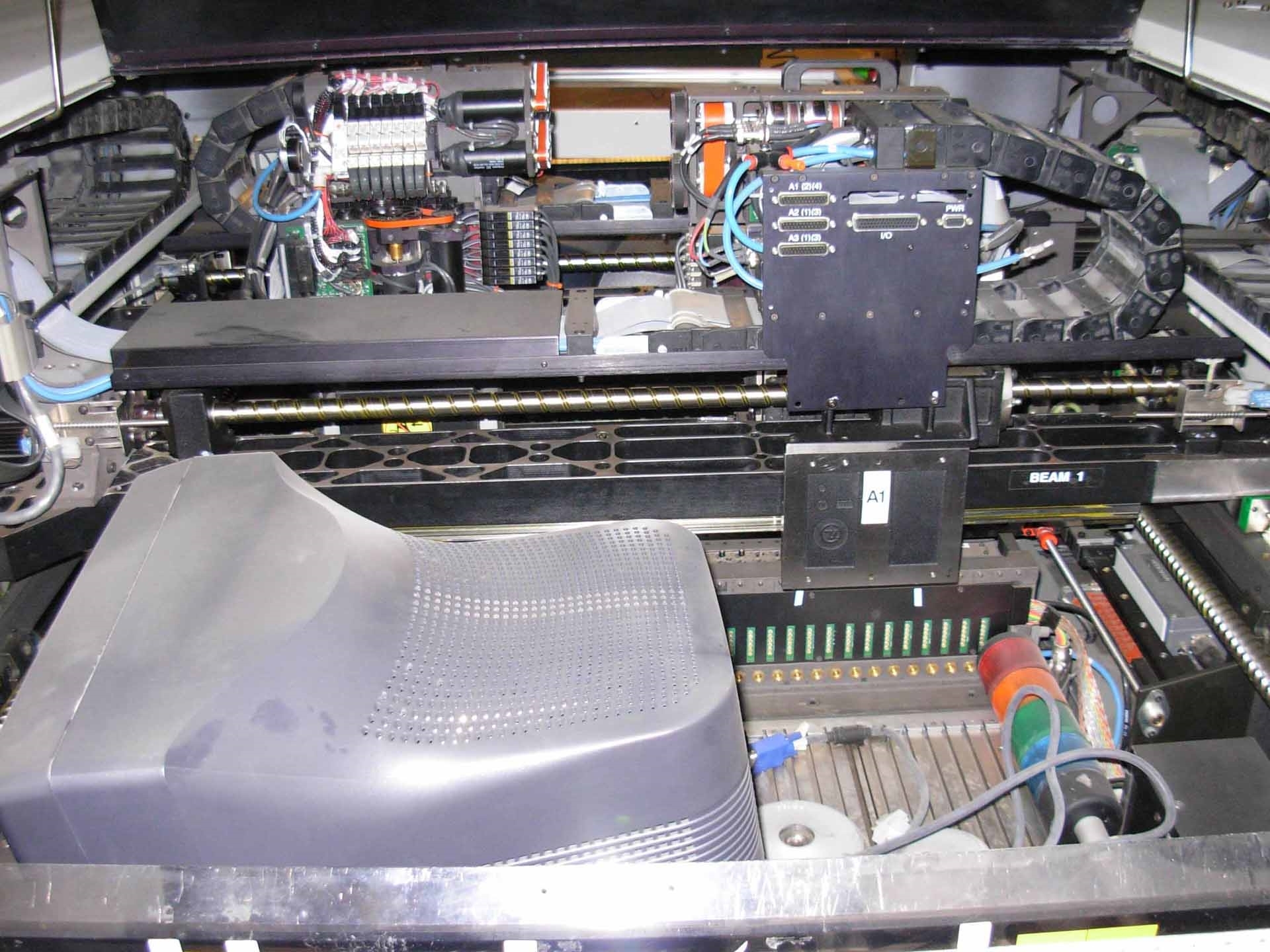

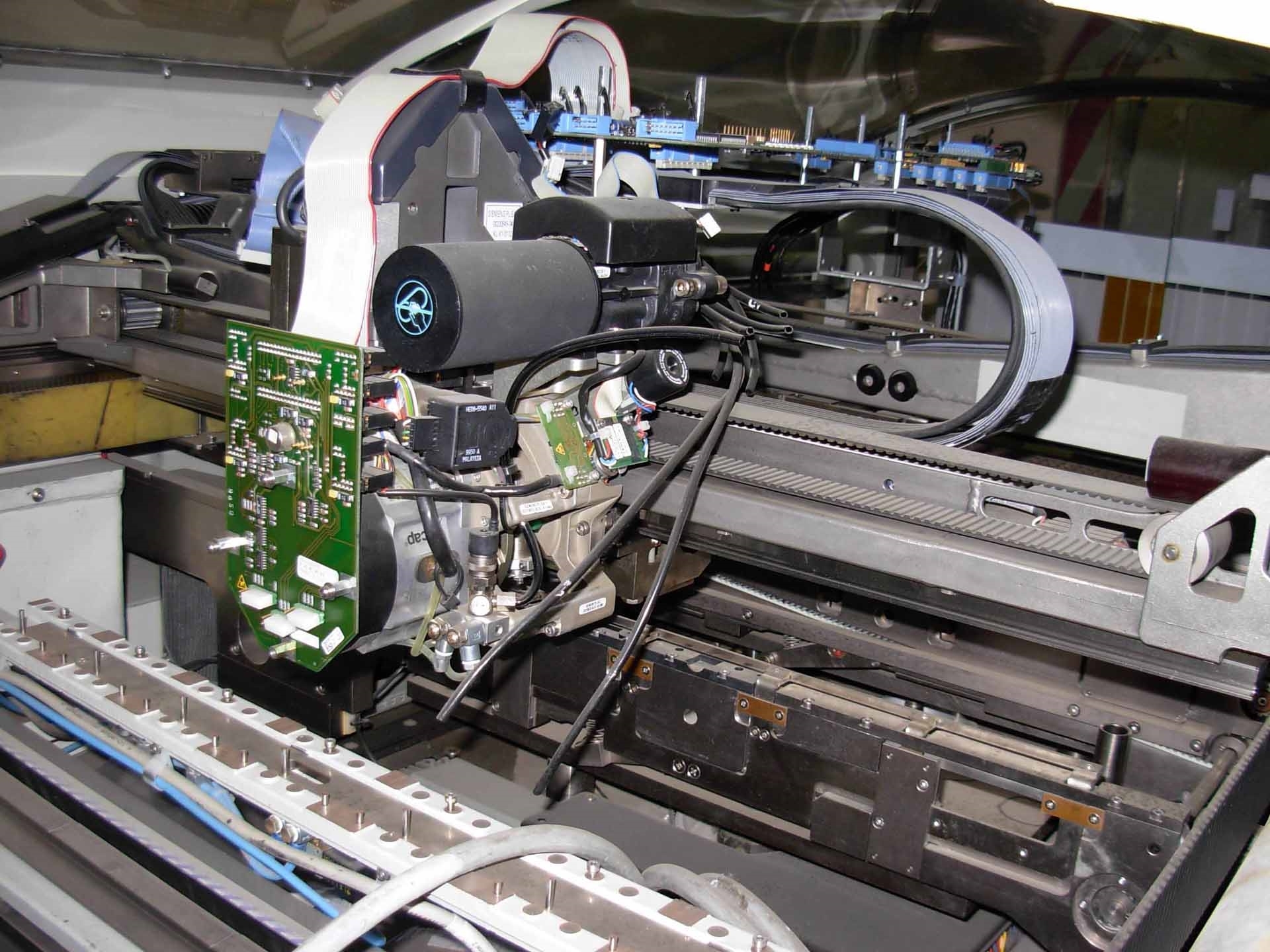

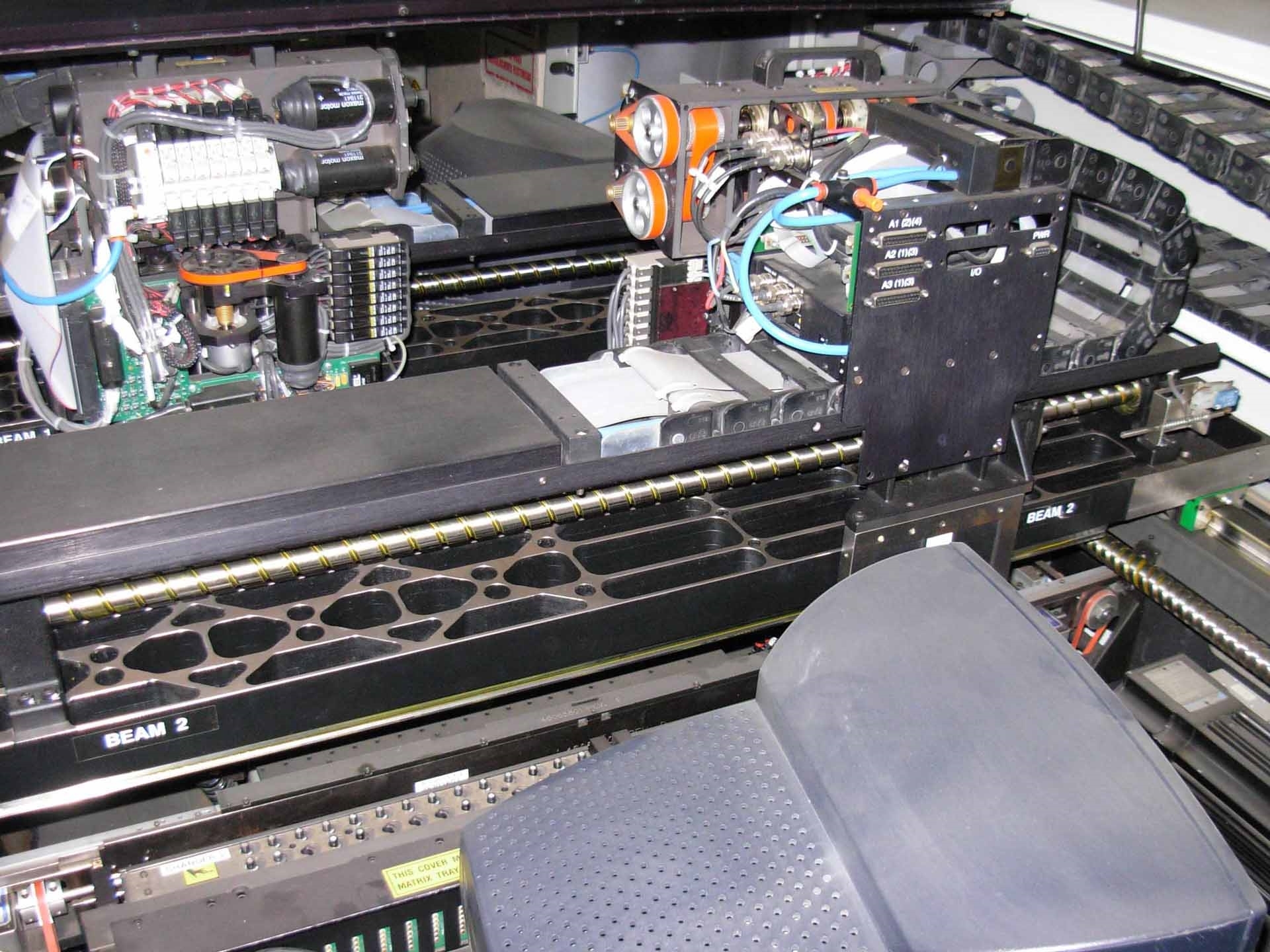

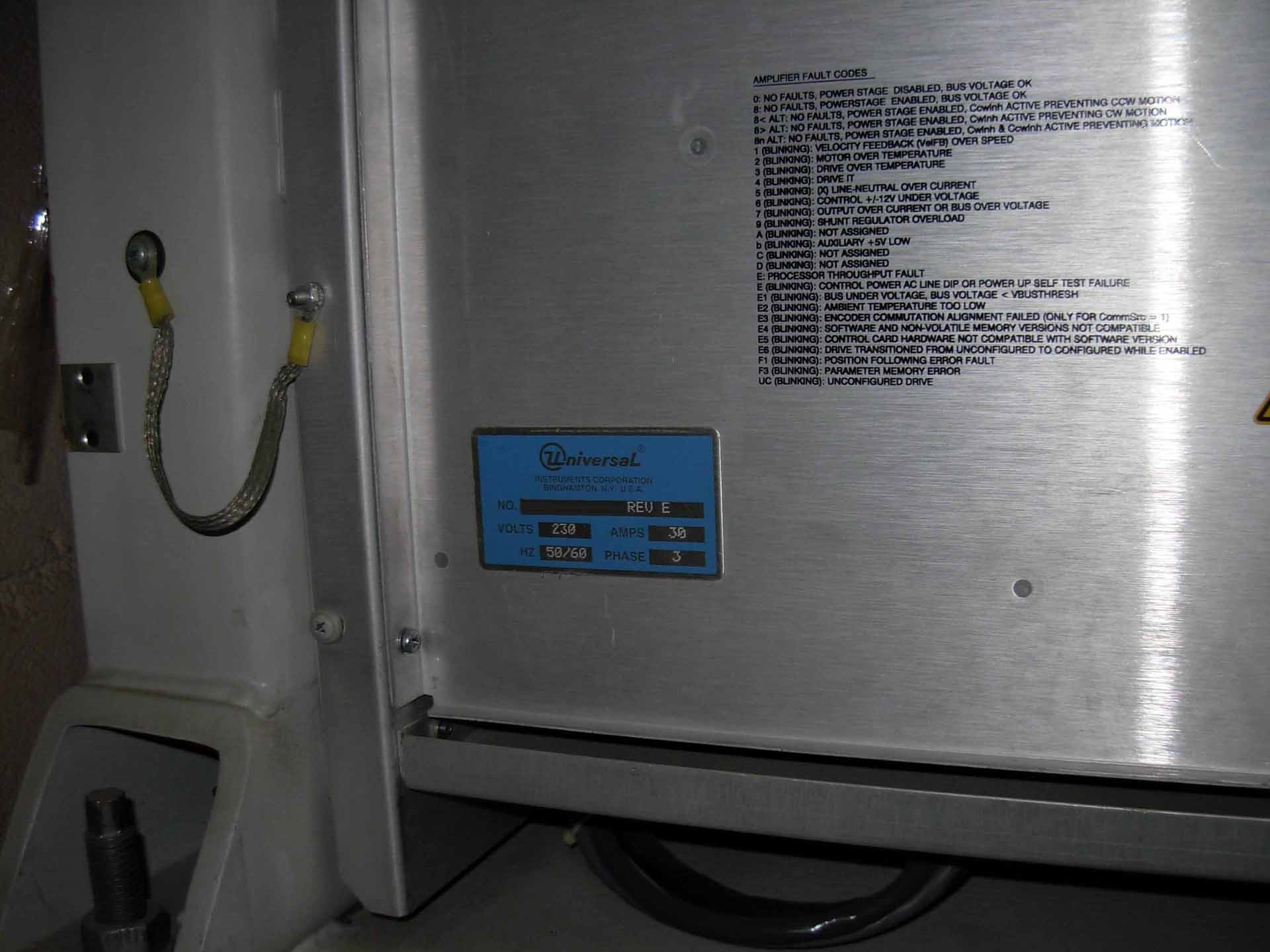

SIEMENS Siplace 80 S20 is a PC board assembly and manufacturing equipment that offers high precision and productivity for automatic placement of SMD components on the PCBs. With its high expandability and clean design, the system is capable of dealing with large throughputs and provides reliable process capabilities for high-precision production needs. Siplace 80 S20 has two primary components, the Machine Control Unit (MCU) and the Placement Unit (PU). The MCU is responsible for controlling the motion, power, communications, and precision of the PU. The PU consists of a mechanism for precision control and generation of signals necessary to place components accurately on the PCB, along with a vision unit for quick identification and posture adjustment of the components. The machine is highly flexible and can be upgraded with additional attachments, such as a component-specific dispensing tool and four feeders that deliver components to the PU. Each feeder consists of two trays: one for components and the other for component storage. This provides the asset with an unlimited supply of components. SIEMENS Siplace 80 S20 is equipped with a variety of safety features, such as an integrated safety light curtain. This allows for continuous monitoring during production and helps detect if an object enters the working area. It also prevents production from being interrupted and helps minimize possible damage to the PU. The model is capable of placing all types of components, including surface mount devices (SMDs), fine pitch connectors, and shipped components. It uses an advanced placement head and a vision equipment to accurately identify components and then adjust the components on the board according to the component-specific placement strategy. Siplace 80 S20 is one of the most powerful and reliable placement systems in the market and it is ideal for any type of production environment. It has an efficient design that can easily handle large production volumes and is fully compatible with the Automated component handling (ACH) System. This allows for easy communication between the unit and other factory production machines. Furthermore, the machine is equipped with various software modules that enable an easy, intuitive operation. This reduces operator training and helps users to get faster, more accurate production results.

There are no reviews yet