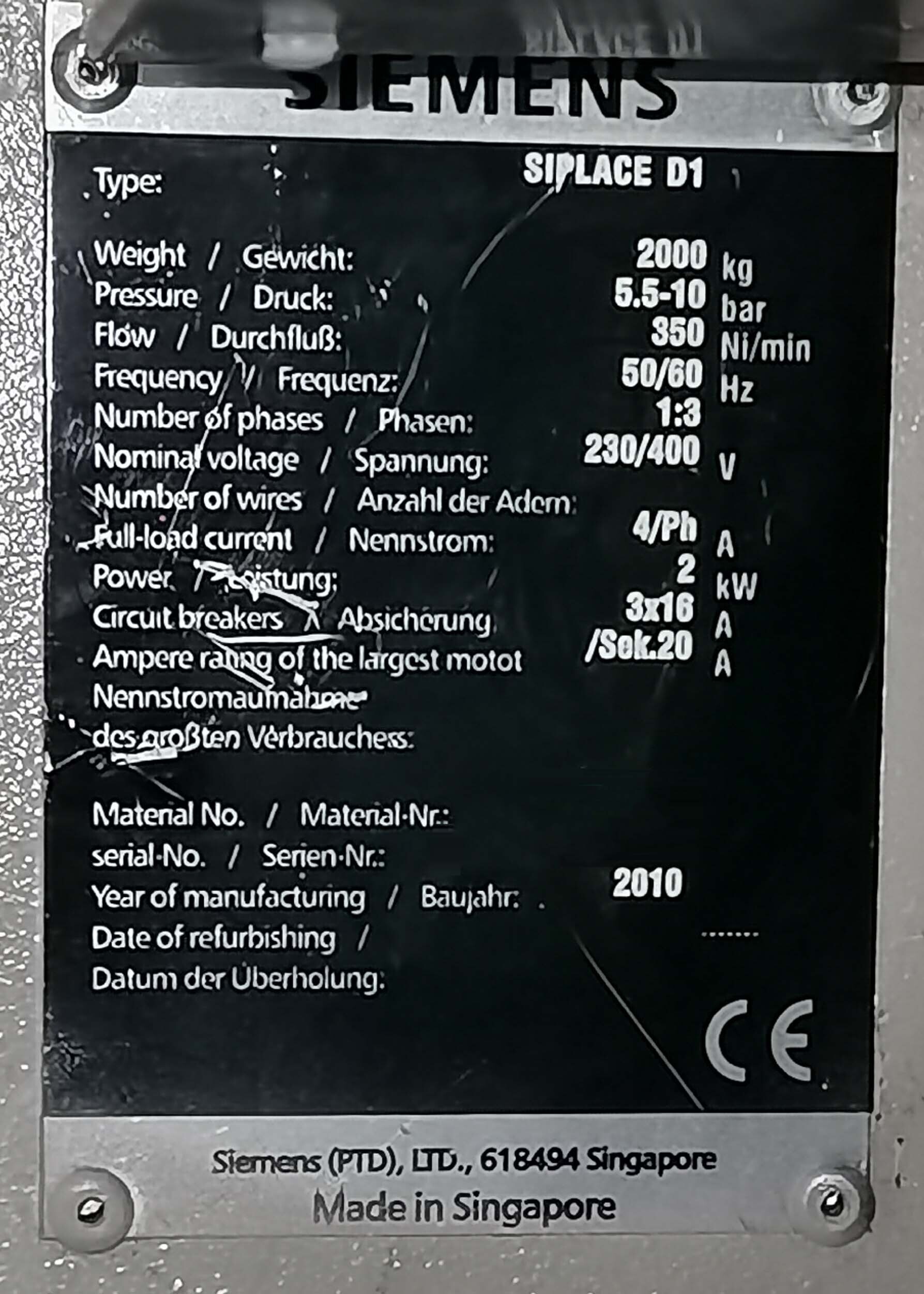

Used SIEMENS Siplace D1 #9301832 for sale

URL successfully copied!

Tap to zoom

ID: 9301832

Vintage: 2010

Pick and place machine

Theoretical value: Up to 20,000 CPH

IPC Value: Up to 13,000 CPH

Accuracy: ±30 μm

PCB Size:

Single track transmission: 50 mm x 50 mm - 610 mm x 508 mm

Double track transmission: 50 mm x 50 mm - 610 mm x 430 mm

PCB Thickness: Standard 0.3 mm - 4.5 mm

Component range: 01005" - 200 mm x 125 mm

Quality pickup rate: ≥99.95%

Feeding capacity: 90.8 mm rails

2010 vintage.

SIEMENS Siplace D1 is a high-tech Pick-and-Place equipment that provides advanced, production-level pc board assembly and manufacturing capabilities. The system is designed to be a complete board assembly and manufacturing station, able to both program and place components on a pc board in a single production cycle. The unit utilizes a unique 3-phase machine with 4-motorized axis for an optimized operational cycle time. The tool's 3-phases of operation include the PLC loading phase, the CAD preparation phase, and the feeding phase. During the loading phase, the programmable logic controller (PLC) prepares Siplace D1 for a board assembly and manufacturing cycle. This includes the setting of parameters, program verification, and other operational steps. During the CAD preparation phase, the computer-aided design (CAD) files provided by the customer are loaded onto the asset. The data loaded contains placement information for all of the components used, allowing the model to automatically calculate optimal placement strategies for each component to ensure high quality and accuracy. The third phase, the feeding phase, involves components being fed from the Component magazine onto a pick-up arm, also known as a pick-and-place head. This arm is then used to pick and place components directly onto the pc board in accordance with the placement data sent during the CAD preparation phase. All of the components are placed in an accurate, consistent, and repeatable manner. SIEMENS Siplace D1 equipment also has a number of built-in safety features to protect against incorrect material placement. These features include X-Y placement touch-thru systems, safety covers, and magnetic and vacuum brakes. Voltage and temperature control of the vacuum valves are also controlled by the system to provide additional stability. To summarize, Siplace D1 is a complete pc board assembly and manufacturing station that provides advanced production-level capabilities. The combination of the three-phase unit with 4-motorized axis and built-in safety features allows for an efficient and reliable board assembly and manufacturing cycle. The machine is designed to provide an ideal solution for small companies and businesses that require a reliable pc board assembly and manufacturing tool.

There are no reviews yet