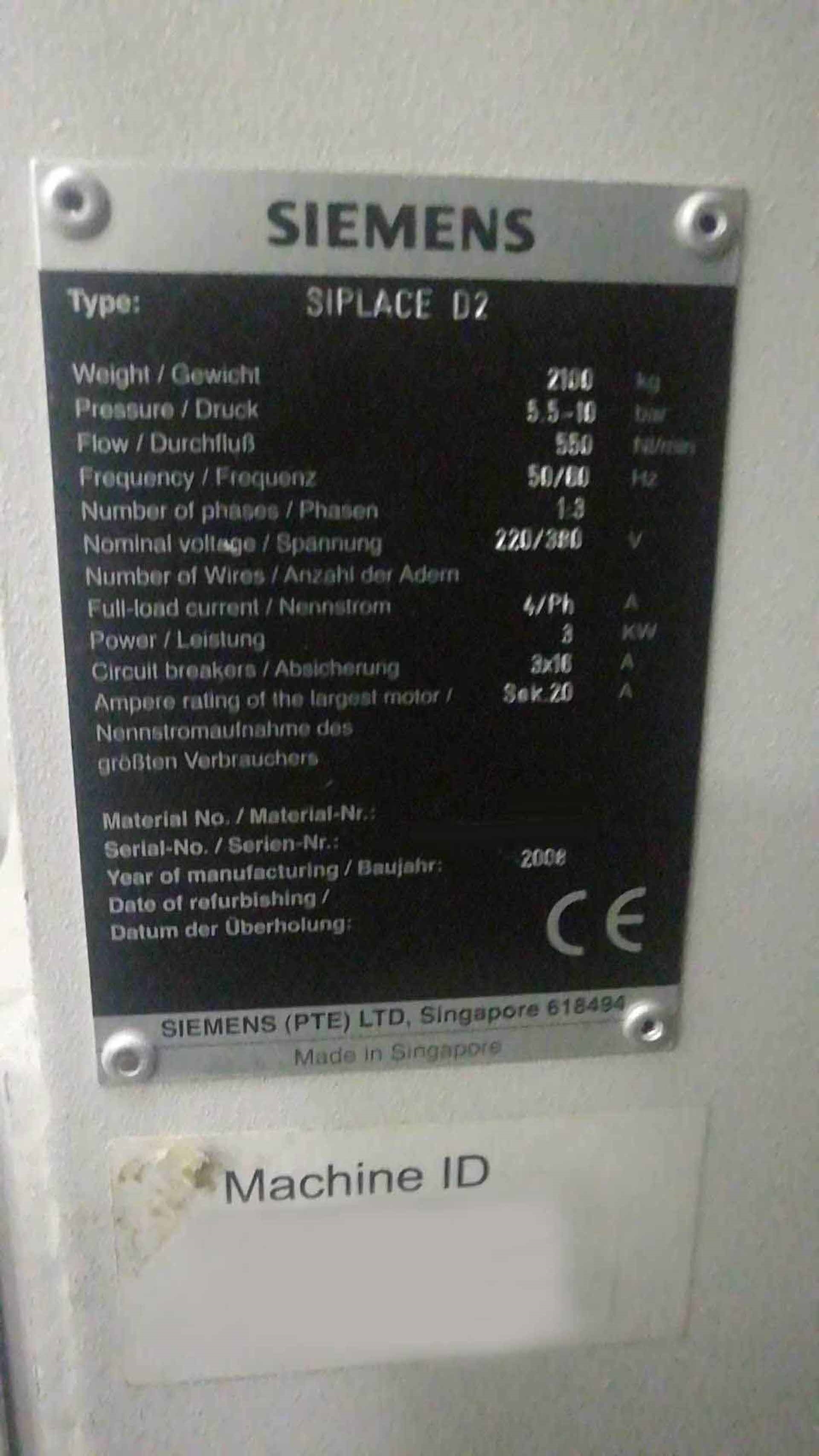

Used SIEMENS Siplace D2 #9230302 for sale

URL successfully copied!

Tap to zoom

ID: 9230302

Vintage: 2008

Placement system

Dual lane

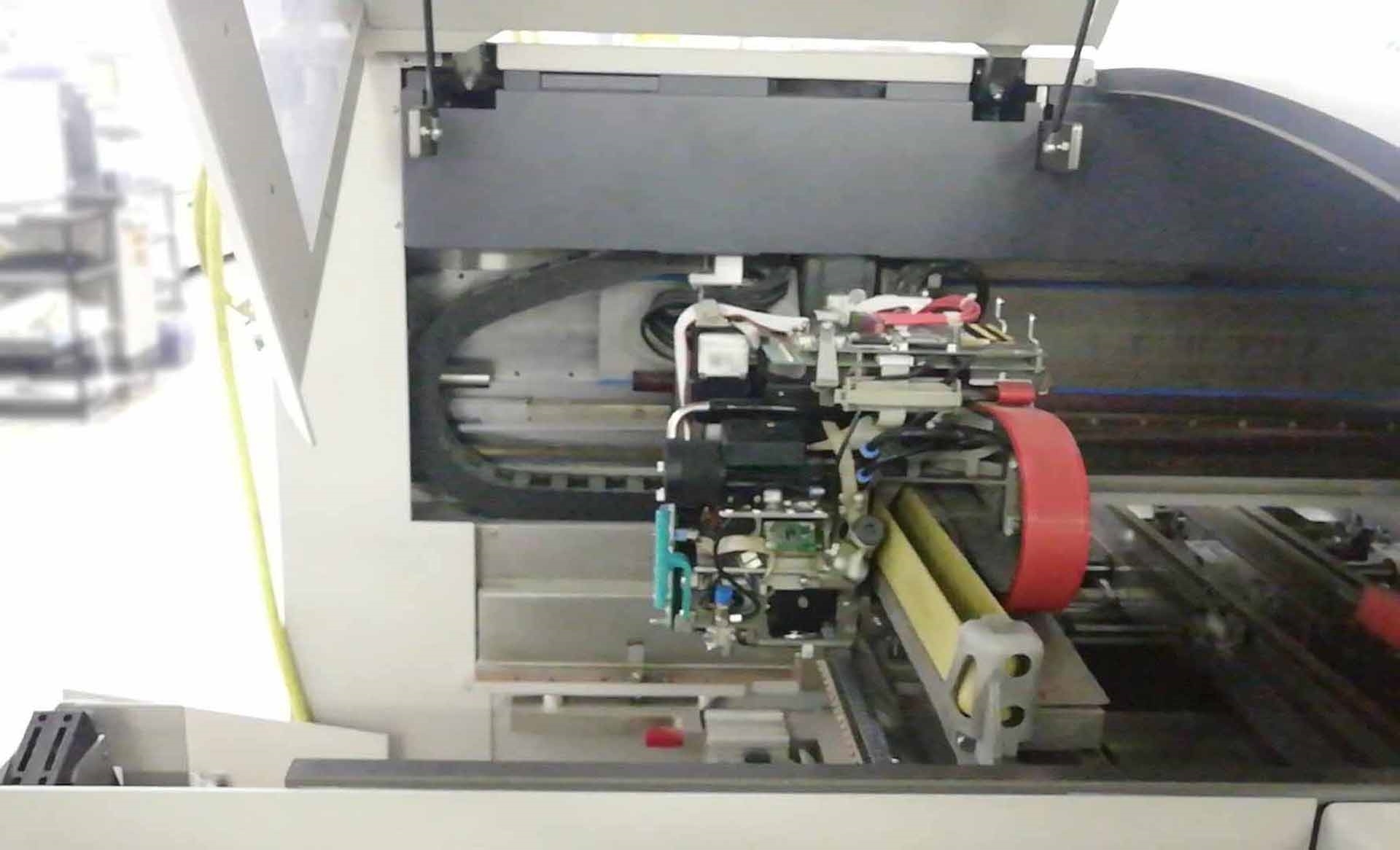

RV12 Head

Camera type: 28 / 29

(2) Trolley carts

2008 vintage.

SIEMENS Siplace D2 is a robust and highly precise pc board assembly and manufacturing equipment, designed to quickly and consistently produce solder paste and component placements. ideal for high-volume, high-mix and small-lot production requirements, Siplace D2 offers unmatched reliability, accuracy, and throughput. SIEMENS Siplace D2's innovative architecture utilizes high-performance 3-axis table and tool positioning, which reduces changeover times, simplifying setup and optimizing throughput. This allows for maximum flexibility in component sizes and quantities, from 0201s to 25x25mm ICs. Siplace D2's advanced vision system further enhances the precision of component placement and helps optimize production speeds. Additionally, the unit's intuitive software-driven operation allows users to easily save and retrieve all production data for future production runs. SIEMENS Siplace D2's reliability and accuracy helps reduce product-to-product variation and is 20-times more accurate than competitive systems, capable of automatically placing components to as close as 0.020″ [0.5mm] tolerances. This makes it ideal for use in a wide range of industries, such as medical device assembly, automotive electronics, telecommunications, semiconductor manufacturing, and more. The machine also benefits from an advanced lighting tool to allow assembly of components under varying light intensities, such as those that may occur during daylight hours or with varying LED lighting. The asset is also fully compatible with SIEMENS proprietary CAM-driven software, which helps ensure all component placements are properly defined and executed. This helps to prevent component mix-ups during assembly, and guarantee that the correct component is being placed onto each board. Siplace D2 pc board assembly and manufacturing model has quickly proven itself as a reliable and efficient solution for high-volume, high-mix and small-lot production requirements. With its robust and precise design, advanced 3-axis table / tool positioning and vision equipment, intuitive software-driven operation, and compatibility with CAM-driven software, the system is ideal for a range of industries from automotive to telecommunications.

There are no reviews yet