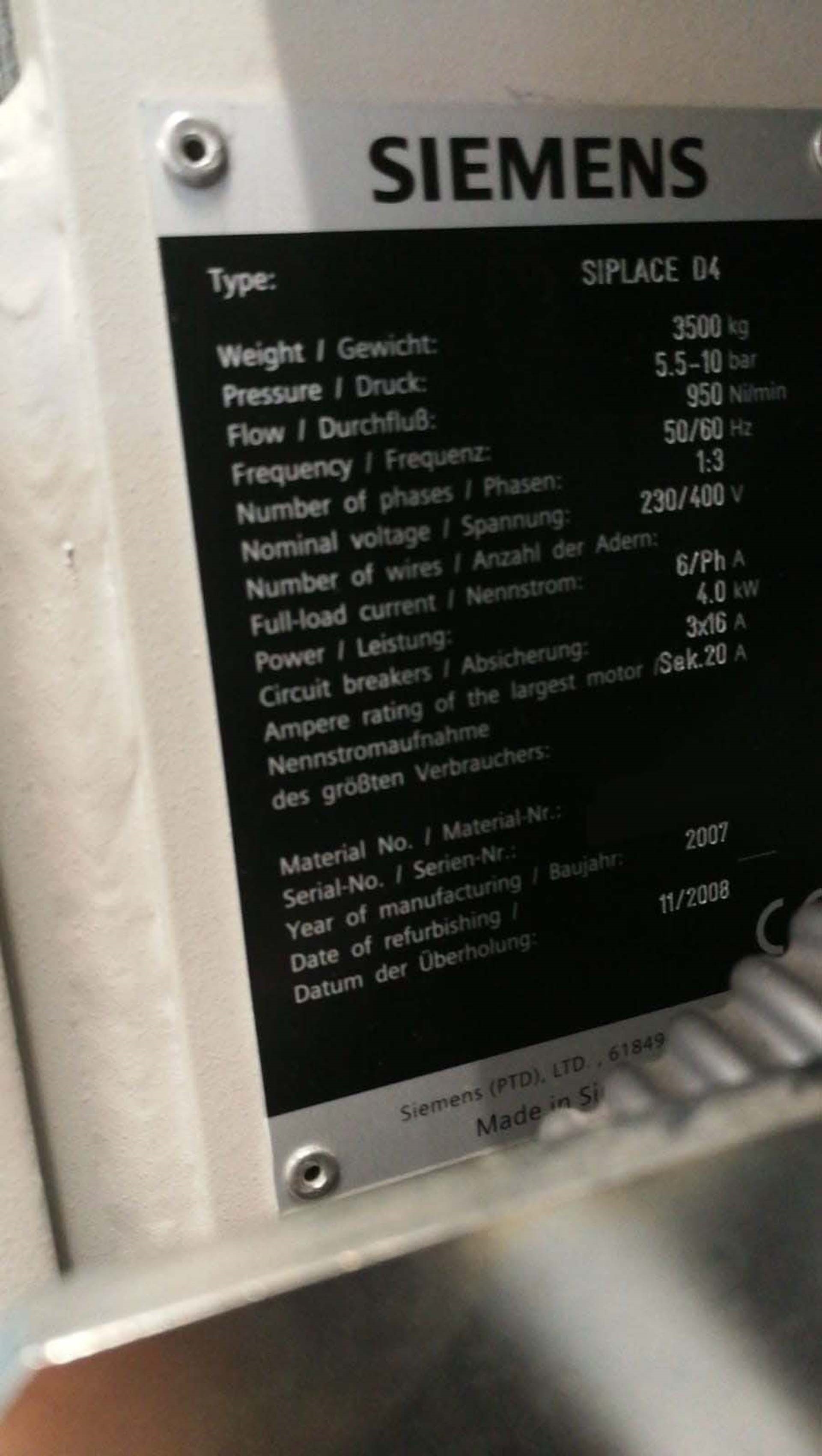

Used SIEMENS Siplace D4 #9258326 for sale

URL successfully copied!

Tap to zoom

ID: 9258326

Vintage: 2007

Pick and place machine

LP Transport: Single right

Transport height: 930 mm

Siplace Pro/OIS and setup center without head

COT

Interfaces COT

SMEMA Adapterbox for D4/D2/D1

Tower light: (2) Colors

(4) Siplace Di-series: 12 Segment

With C+P head

(4) Nozzle changers

With (12) C+P Heads

(4) Changeover table

Feeders:

Qty / Size

(164) / 2x8 mm

(44) / 3x8 mm SL

(49) / 12/16 mm S

(17) / 24/32 mm S

(2) / 44 mm S

(1) / 56 mm S

(1) / 72 mm S

(1) / 88 mm S

Tables:

COMPON Feeder change-over table

(5) COMPON Feeder change-over table with mobile

2007 vintage.

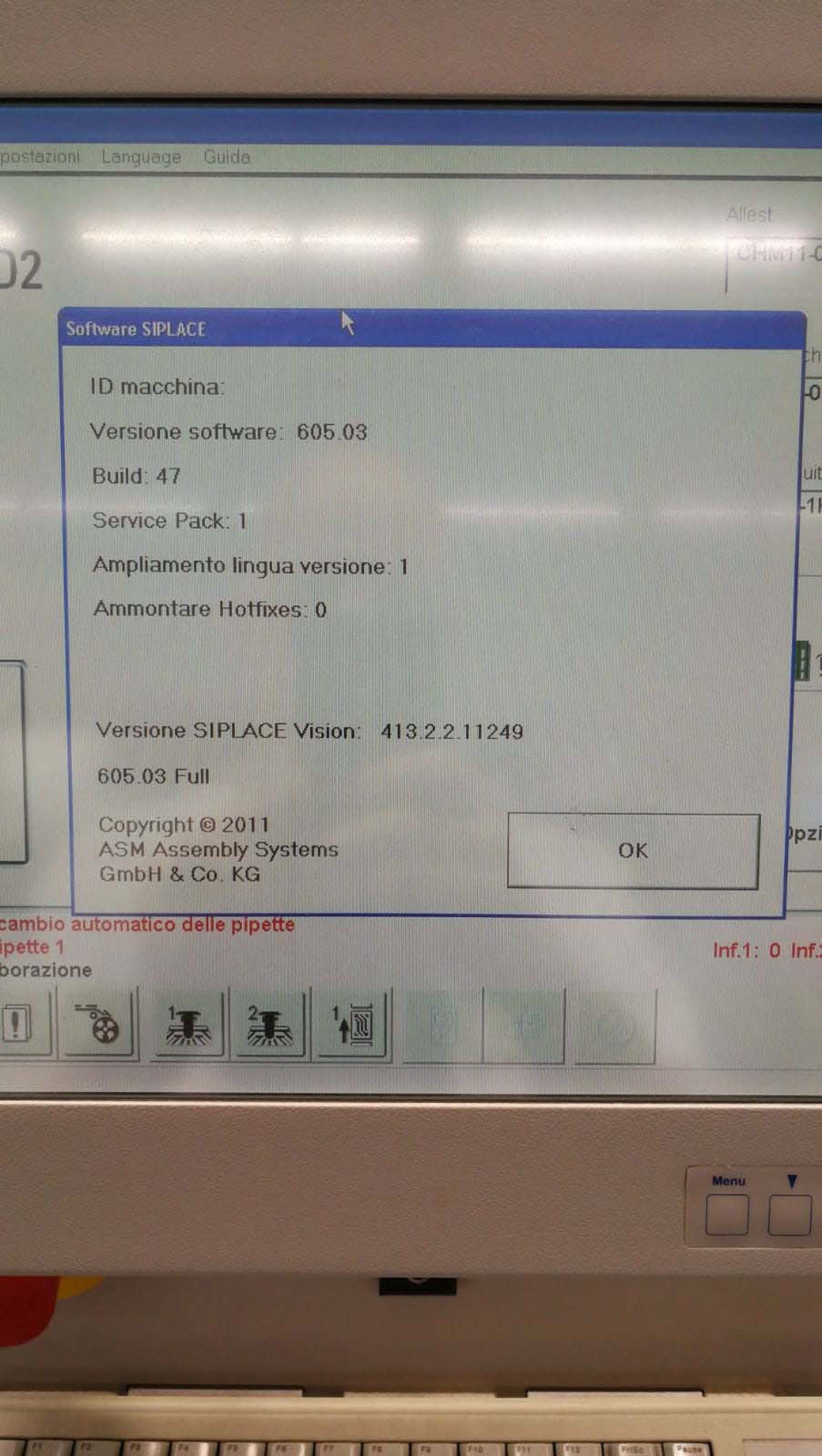

SIEMENS Siplace D4 is a pc board assembly and manufacturing equipment designed to make the production of complex designs more efficient. It is a versatile solution that has the ability to take on jobs of any complexity and size, from very small prototypes to large-scale production batches. It is capable of accurately placing components down to 0201 size (which is 0.02 inches by 0.01 inches) with a high placement accuracy of ±30 µm. Additionally, it can process closely spaced and heavily populated boards with no production delays. Through an automated programming process, the system reduces the time it takes to prepare a production cycle. The unit is geared with a robotic arm, vision machine, advanced software, and numerous user-friendly features that have been designed to streamline manufacturing process. By using the vision tool, the set-up of each machine is tailored to pick-and-place results to meet consistent quality standards. The process can employ automation or manual adjustment to pick the correct component, making it easily adjustable for parts that can't be automatically detects and classified. Siplace D4 also supports 3D vision detecting for components such as LED's and connectors, allowing it to form accurately even the complex boards. Additionally, it is designed to detect PCB abnormalities and creates a record of any shortcuts or interferences for later review. The asset has a fully adjustable process to maximize production speed and meeting the production needs. The model can identify components twice as fast as manual processes, enabling a high-throughput production. It is compatible with up to 44 simultaneous feeders, allowing it to produce batches of varying sizes. The systems come fully automated, allowing for hands-free production, increasing efficiency and safety. While in use, the equipment carries out several diagnostic and maintenance logs that will alert the user to any malfunctions or abnormalities. The system can be integrated into any conveyor unit and easily expands to handle higher production throughputs. Overall, SIEMENS Siplace D4 is one of the most reliable pc board assembly and manufacturing solutions available today. It provides users with a fast and precise set-up of production cycles, accurate and high-quality placement of components, and quick diagnostics. Its advanced features and safe operations help to improve production times and create a reliable machine that can be integrated into any operations.

There are no reviews yet