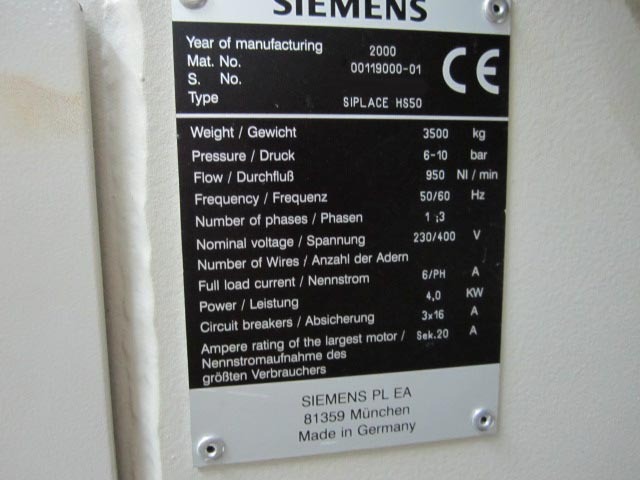

Used SIEMENS Siplace HS50 #148726 for sale

URL successfully copied!

Tap to zoom

SIEMENS Siplace HS50 is a high speed pick-and-place equipment for large volume assembly of printed circuit boards (PCBs). The system is equipped with a high speed linear motor technology that is capable of placing up to 50 components per second, making it well suited for high-end integrated circuit (IC) packages such as ball grid arrays (BGA) and chip scale packages (CSP). The unit is designed for flexibility and automation, with a fully integrated belt-fed conveyor line with pick-and-place heads that can be easily adjusted to accommodate a wide range of components. Featuring a modular design, the machine can be adapted to a variety of production scenarios and enables the user to increase the tool's throughput dynamically by adding additional conveyor feeders and pick-and-place heads. SIEMENS SIPLACE HS 50 is capable of handling components as small as 0201 and as large as 50 x 50 mm. The software integrates a variety of placement algorithms to ensure efficient results, as well as a comprehensive track and trace asset that monitors the board and componentss histories. The model features vacuum nozzle tooling and accepts components stored in trays or on tapes, enabling the use of automated feeder systems. A key feature of SIPLACE HS-50 is its vision equipment that is used to align parts with high precision. The vision system eliminates the need to adjust components or manually mark them in order to place them correctly on the board. Additionally, the unit's flexibility allows it to be easily integrated into automated lines and controlled by a centralized machine that can monitor multiple stages of the production process. Siplace HS50 is engineered for ultimate productivity and accuracy. Each of the 50 nozzles are capable of achieving placement accuracy better than 0.02 mm and can be replaced quickly to minimize down time. The tool also includes an advanced nozzle maintenance program and is capable of monitoring the condition of its parts in order to reduce maintenance costs. For an automated pick-and-place asset, SIEMENS SIPLACE HS-50 is a reliable and cost-effective solution for the production of high-end PCBs. Its combination of speed, accuracy, flexibility, and scalability make it an ideal choice for any production environment and it can help producers quickly and accurately manufacture a wide range of PC boards.

There are no reviews yet