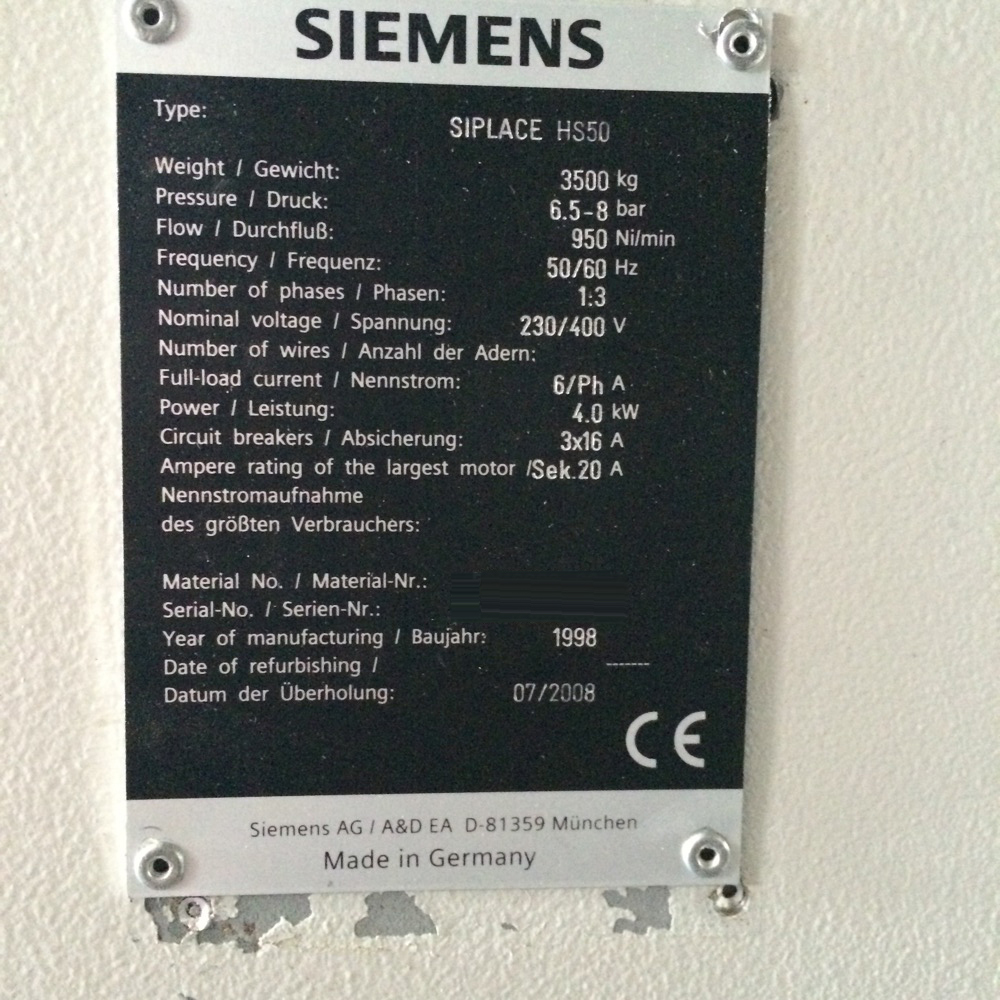

Used SIEMENS Siplace HS50 #9073692 for sale

URL successfully copied!

Tap to zoom

ID: 9073692

Vintage: 1998

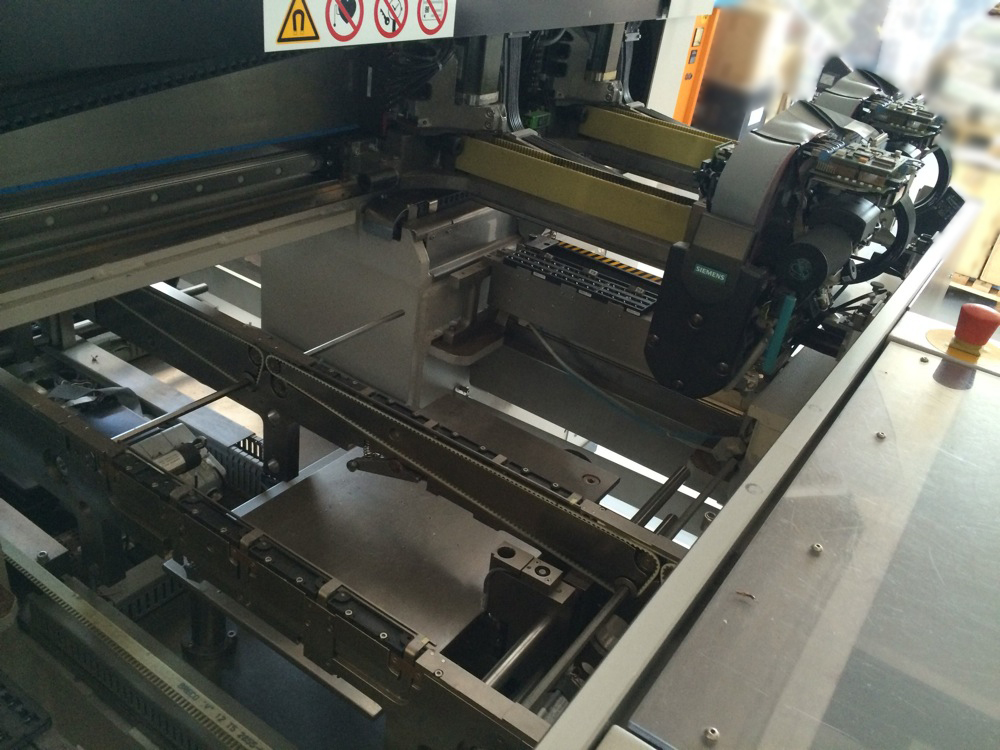

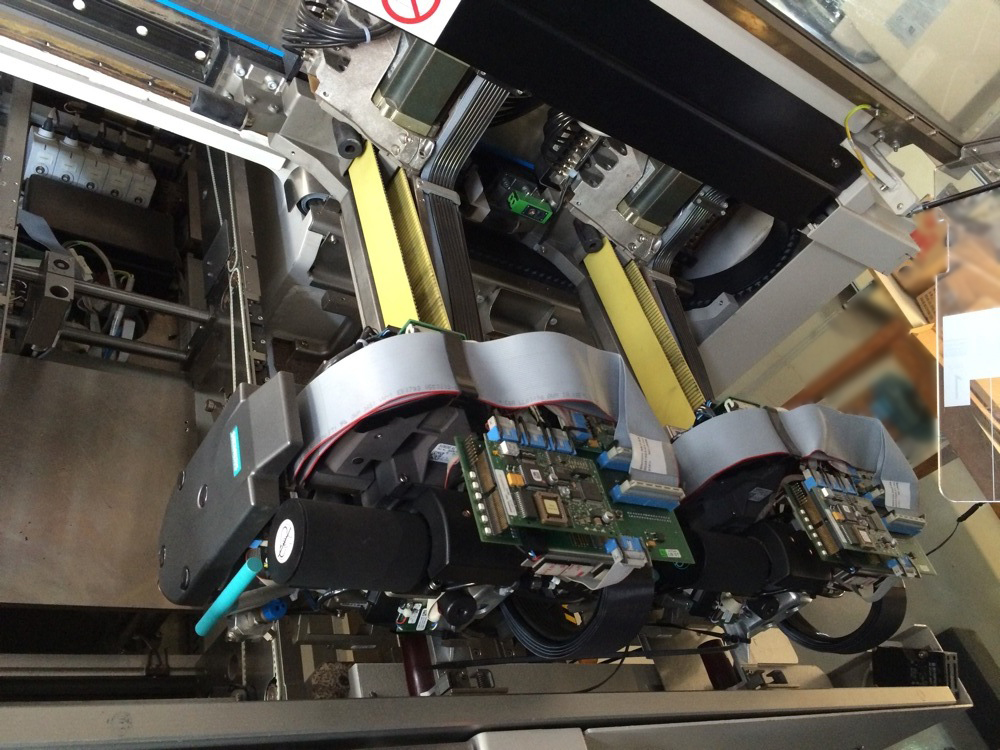

Pick and place system

Pressure: 6.8-8 BAR

Flow: 950 NI/min

230/400 V, 1-3 Ph, 50/60 Hz

1998 vintage.

SIEMENS Siplace HS50 is a reliable and efficient pc board assembly and manufacturing equipment designed to help operators increase productivity and reduce cost. It is easy to use and highly programmable, making it suitable for various types of production. The system includes a movable rail-mounted head with one to three heads, a conveyor and a pre-feeder, allowing for simultaneous pick-and-place of multiple components. The heads use a laser-based head vision alignment unit, which ensures high accuracy and repeatability. The conveyor's programmable design allows it to optimize the travel time from first component placement to last component placement, making the machine capable of producing high volume production with low cycle time. SIEMENS SIPLACE HS 50 also features an intuitive software tool for easy operation. The software allows the operator to store and recall past job data, program components, monitor machine status, generate reports, and more. It also enables the machine to diagnose any potential issues and alert the user of any component placement errors. The software can be easily updated and upgraded with the availability of new features. SIPLACE HS-50's fully automatic operation asset allows for same-day setup, making it an attractive choice for manufacturers who want to reduce start-up time and cut costs. The hardware is designed to minimize downtime, thanks to its modular design with quick changeover of setup and fixtures. Its multi-pass production allows more components to be placed in the same cycle, with minimal operator intervention. Overall, SIEMENS SIPLACE HS-50 pc board assembly and manufacturing model is a versatile and user-friendly tool that helps manufacturers of all sizes to increase efficiency, reduce costs, and pre-empt downtime. It is suitable for various types of production, and its intuitive software equipment allows operators to quickly and accurately program parts and monitor machine status. It is a reliable and cost-effective solution for manufacturers who want to optimize their production.

There are no reviews yet