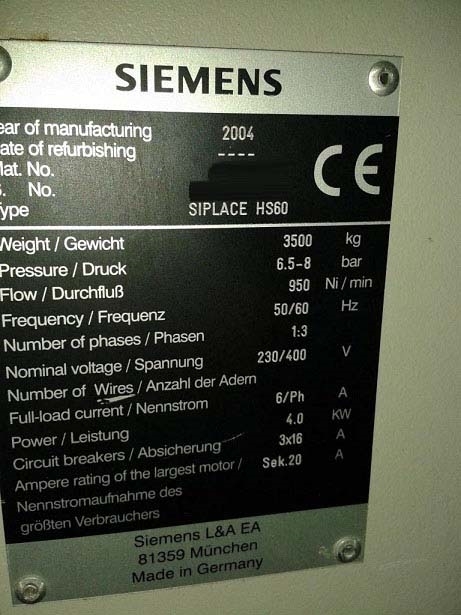

Used SIEMENS Siplace HS60 #9042801 for sale

URL successfully copied!

Tap to zoom

SIEMENS Siplace HS60 is a high-speed pc board assembly and manufacturing equipment designed for automated placement of surface mount components. It is equipped with two Laser Vision Placement Heads (LVPHs), each head capable of placing up to approximately 20,000 components per hour, making it capable of placing a total of 40,000 components per hour. The LVPHs are able to accurately place components with a placement accuracy of up to ±50 µm. The HS60 is equipped with a high-resolution 16 Megapixel stereo 3D vision system for component recognition and placement accuracy of ±20 µm. It also features online visualization for process reliability and quality assurance. This unit is capable of processing a wide range of components such as 1206 down to 01005. The HS60 also comes with a component placement area of 556 x 508 mm per placement head and an integrated transport machine for up to 6 feeders per head. The HS60 is equipped with a user-friendly, high-performance graphical user interface that enables intuitive programming. This tool is suitable for the placement of varieties of components such as manually fed components or which are conveyed into the placement chamber. It also features a built-in self-testing asset for shortening the setup times, allowing it to be investigated on-the-fly and for fast troubleshooting. The HS60 is capable of flexible, high-speed production and can be used in the production of high-mix, low-volume PCBs. The HS60 incorporates features such as tool motion monitoring to ensure the correct tool placement throughout the production process, as well as an automatic calibration and centering model. It also incorporates a tray loading equipment, enabling a variety of components to be placed onto the PCB simultaneously. The system also has an integrated transport unit for up to 8 tape-fed components. The HS60 machine is equipped with advanced climate controls to maintain consistent production environment temperature. Additionally, the placement heads are designed to reduce dust, emi/emi risks, and vibrations. Moreover, the HS60 is equipped with an advanced SMEMA-compliant interface for communicating with external loading/unloading systems. The HS60 is a comprehensive and reliable pc board assembly and manufacturing tool from SIEMENS that provides reliable accuracy, enhanced yields, shorter production cycle times and increased overall productivity. The asset is designed for the placement of a wide range of component types and can be used for both high-speed and low-volume production processes.

There are no reviews yet