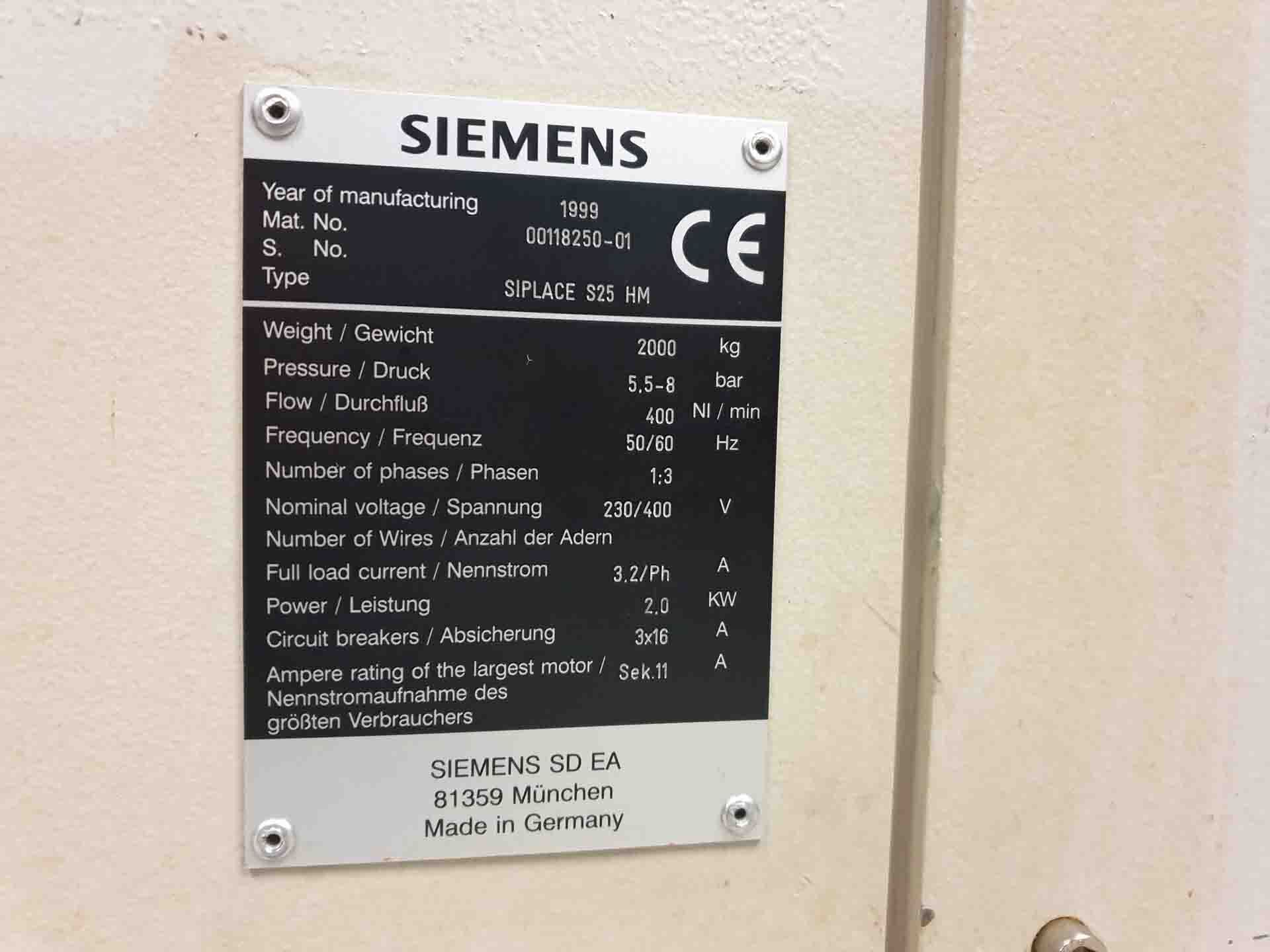

Used SIEMENS Siplace S25 HM #293615351 for sale

URL successfully copied!

Tap to zoom

SIEMENS Siplace S25 HM is an advanced pick-and-place machine designed for the assembly and manufacturing of printed circuit boards (PCB). The machine is capable of processing up to 25 component placements per second, making it one of the fastest in its class. SIEMENS SIPLACE S25HM accommodates up to 11 feeders, with a capacity of 48 component pick-up positions. It can be equipped with a conveyor belt, a vacuum track transport, or a palletizing option to provide flexibility in component positioning. Additionally, the machine offers a unique component testing feature that improves accuracy and eliminates potential bad placements. The S25 HM makes use of cutting-edge Vision and Height Measurement technology for component identification, placement accuracy and inspection. A high-resolution dynamic camera system scans the component codes from the component library, which can then be used to locate the component exact position. This feature, combined with the Height Measurement technology, ensures the highest quality placements. Additionally, advanced software allows for seamless integration with the customer's existing production line, as well as compatibility with many CAD programs. SIPLACE S-25 HM is a reliable, user-friendly machine designed to meet the needs of demanding, high-volume PCB assembly and manufacturing. Its advanced features provide the highest levels of speed, accuracy, and flexibility, while its robust design ensures maximum stability, reliability and user safety. Its high-quality components, features, and software make the S25 HM an excellent choice for production lines in many industries.

There are no reviews yet