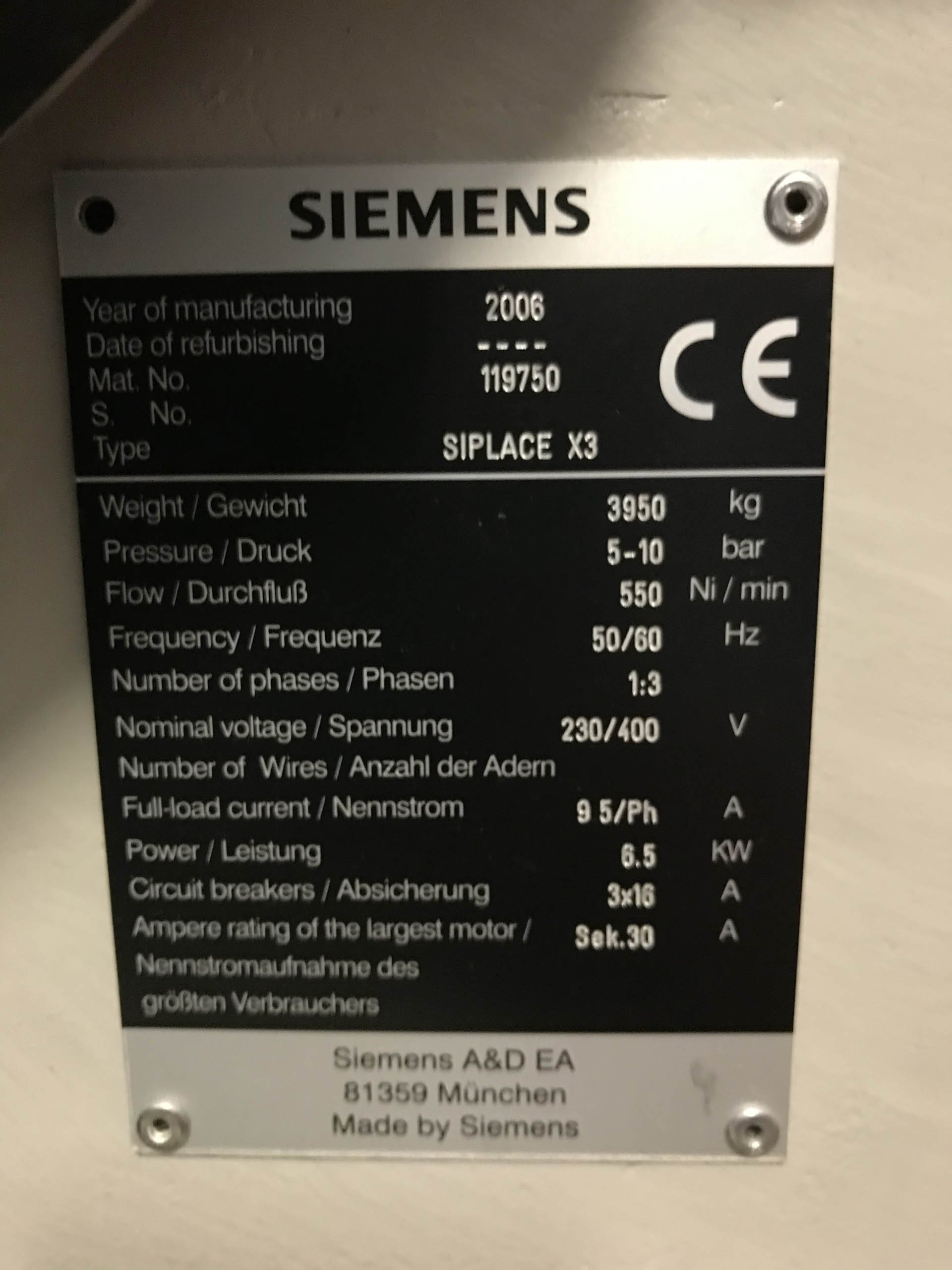

Used SIEMENS Siplace X3 #9354648 for sale

URL successfully copied!

Tap to zoom

ID: 9354648

Vintage: 2006

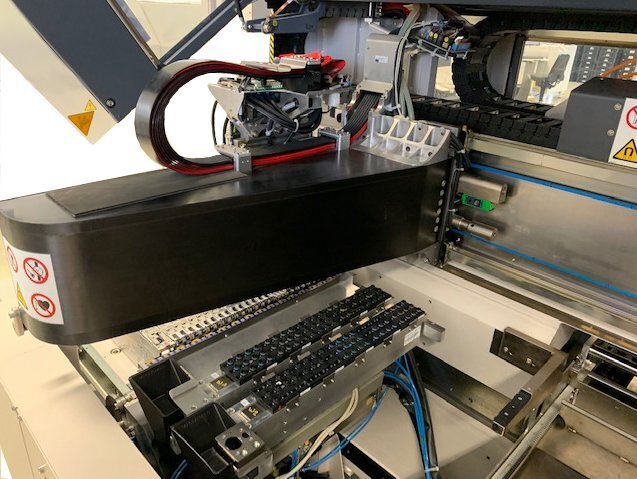

Pick and place machine

Single line

Feeder: S Type

(2) DLM-CP12 Heads

Twin head

(4) Feeder trolleys

(28) RV Cameras: 24.2 x 24.2

(29) RV Cameras: 32 x 32

(33) IC Cameras: 66 x 50

2006 vintage.

SIEMENS Siplace X3 is a modern machine for PC board assembly and manufacturing. It is designed to reduce manufacturing time, increase throughput rates and improve quality. This equipment is designed to be used in connection with other machines in the Siplace family to build large or complex boards. The X3 utilizes a 3-axis gantry system to move and place components accurately and quickly onto a printed circuit board. An infeed gantry is used to feed components, and a CCD camera is used for component recognition. For larger components, a pick-and-place head is used to grab and place components onto the board. The X3 also features advanced programming options including integrated placement optimization, 3D vision, and multi-feeder capability. Placement accuracy is improved with the X3's vision unit, which checks for correct components and presence of a component in the feeders before placement. This machine also has integrated measurement capability to measure components before and after placement, verify paste deposits, and detect missing or faulty components. The X3 has a flexible and modular design, allowing for easy integration into complex production lines. The X3 is equipped with a number of advanced tools and features such as feeder calibration, quick-change heads, and intuitive user interface. It also allows for easy programming and updating of recipes and placement sequences. The feature set includes a comprehensive range of options for control of component positions which are not only accurate in their placement but also very quickly operated. With Siplace X3, a number of key performance parameters such as speed, accuracy, and repeatability can be greatly improved. The tool is also able to perform hot gas soldering processes, which can reduce production time and minimize the number of process steps. The asset also offers advanced feeder calibration capability, which is used to ensure accuracy and minimize downtime. Overall, SIEMENS Siplace X3 is an advanced model designed to improve the speed, throughput and accuracy of PC board assembly and manufacturing. It is capable of precise and fast component placement, as well as hot gas soldering and feeder calibration for improved accuracy. It is well-suited for larger components and complex production lines, and its user-friendly interface and advanced features are a great advantage.

There are no reviews yet