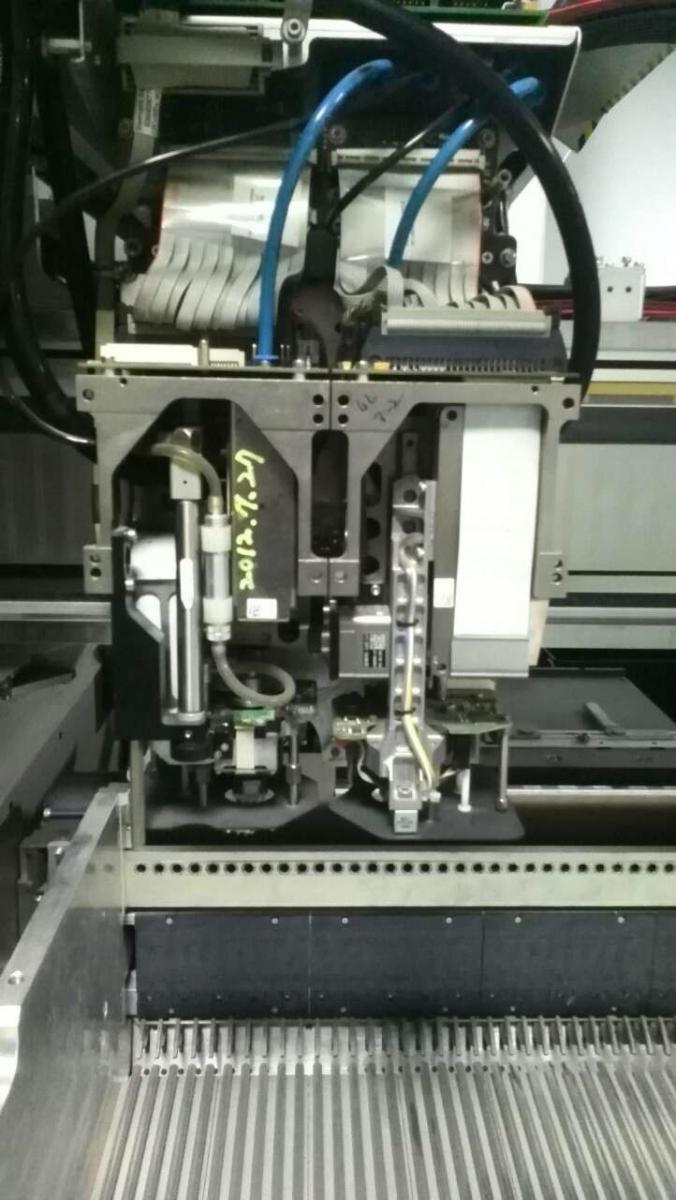

Used SIEMENS X4 #9121962 for sale

URL successfully copied!

Tap to zoom

ID: 9121962

Vintage: 2008

Pick and place machines

Dual lane

(2) RV12 Heads

(2) TH Heads

Feeder not included

2008 vintage.

SIEMENS X4 is a complete pc board assembly and manufacturing equipment designed to bring at-scale, reliable, and cost-effective manufacturing to the next level. It is a fully automated manufacturing process that incorporates the latest in industrial manufacturing technologies and processes. X4 is composed of three main components: the Machine Frame, the Machine Control Unit, and the Material Feed Unit. The Machine Frame houses several major components, including the Scanner, the Controller, and the Assembly Platform. The Scanner is what actually creates the assembly schematics and is responsible for drawing out each individual component's placement on the board. The Controller is comprised of the Processor and the Operating System. This is the brains of the operation and ensures that all operations are conducted efficiently and in time. It also optimizes the manufacturing process by assigning jobs to specific machines. The Assembly Platform is where the material for the boards is laid out by the material feed unit. This platform allows for quick and precise assembly processes and makes SIEMENS X4 unit suitable for high-speed production. The Material Feed Unit is designed to aid in the fast and accurate assembly process. It takes the components from the feeder trays, scans the parts, and places them onto the assembly platform. This allows for quick and accurate part placement and overall improved performance of the machine. Last but not least, the Machine Control Unit is an important component of the tool and is responsible for monitoring and adjusting the asset's performance. It oversees the operations and can even be used to make sure that the model runs efficiently and consistently. X4 provides an overall streamlined manufacturing experience that allows for optimal performance and cost savings. Its use of modern manufacturing technologies and processes allows for efficient production and higher quality products. Furthermore, its easy setup and straightforward operation make it ideal for a variety of environments and conditions.

There are no reviews yet