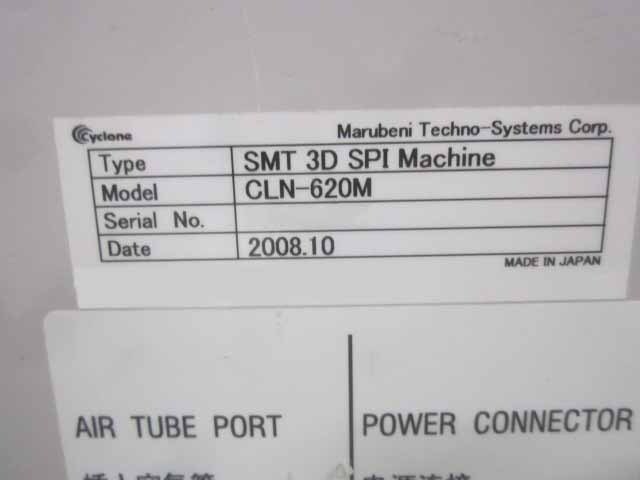

Used SMT CLN-620M #293608840 for sale

URL successfully copied!

Tap to zoom

ID: 293608840

Vintage: 2008

3D Solder Paste Inspection (SPI) system

Rear fixed

PCB Flow: Left to right

2008 vintage.

SMT CLN-620M is an automated in-line pick and place machine designed for quick and efficient production of printed circuit board (PCB) assemblies. It is capable of handling component placements between 0201 and 55x55mm and is ideal for high-volume manufacturing and prototyping applications. Thanks to its advanced vision alignment system, this reliable machine offers an extremely high precision rate of 0.05mm for high-density component placement. CLN-620M is also equipped with an interactive graphical operator interface, providing complete operational control and setup of component-specific placement parameters. Moreover, it can be configured for both single or dual-track operation and does not require constant operator supervision, making it ideal for automated production lines. Additional features include an integrated component identification system, which automatically reads the component data from optical or barcode labels. Furthermore, the machine features a single-track-width component-feeding area, enabling both fast component loading and unloading, while also reducing the amount of time required for component changeover. SMT CLN-620M is also designed to operate efficiently, enabling simple and low-maintenance operation. It includes an exceptionally low-maintenance belt conveyor for easy cleaning and maintenance, as well as a linear induction motor for quiet and smooth operation with no mechanical wear. In addition, there are a number of accessories that can be used in conjunction with CLN-620M. Options include additional component carriers, vibratory feeders and a slot nozzle-interchangeable tool, which can be used to maximize the system's flexibility. Overall, SMT CLN-620M is an excellent choice for high-volume PCB assembly and manufacturing applications. It combines the latest in processing, vision and computer technology, enabling fast and accurate component placements, while also offering highly reliable operation. Its design is easy to maintain and setup, making it suitable for use in automated production lines and cost-effective automated prototyping applications.

There are no reviews yet