Used SONY CSM-200B and CSM-200C #186321 for sale

URL successfully copied!

Tap to zoom

ID: 186321

Data storage system

CSMBF Left tower

CSMD Right tower

(2) Drives: SONY SDZ-130

(2) Power units: SONY APS-168 Part 1-468-614-13

(2) Power units: CSMA-PSL

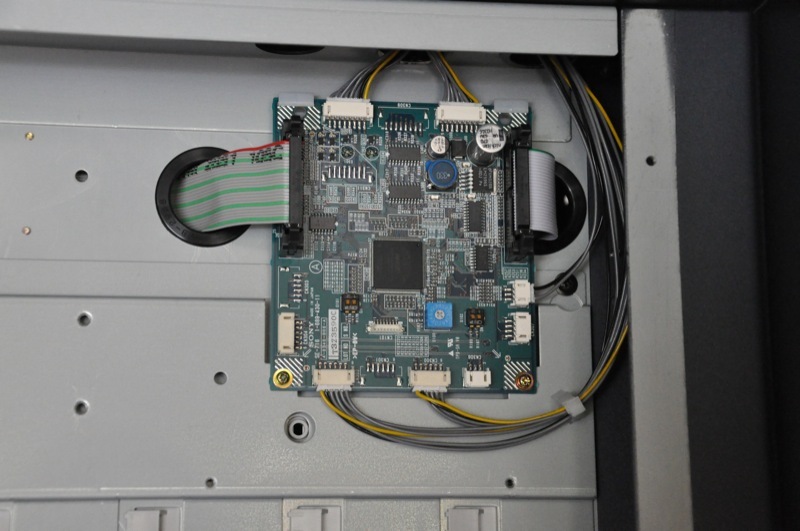

(4) Controller boards: SONY IF-923 or 1-698-428-11

(4) Power cords needed for each unit

Arm inserts tapes in to drive

Tapes can be inserted into the 2 doors below the computer console

After tapes are inserted, a laser reads the tapes and inserts them into the correct location.

SONY CSM-200B and CSM-200C are high-end PC board assembly and manufacturing systems designed to meet the needs of today's demanding electronics industry. The CSM models offer a wide range of features which make them ideal for a variety of assembly applications, from small - to large-scale PCB production. They provide high levels of productivity and reliability, allowing end-users to achieve the highest standards of productivity in their application. The core of the equipment is a vision camera, which uses advanced image-recognition technology to identify printed components as well as errors in solder joints during the assembly process. This ensures a high quality output, with fewer errors and fewer rejects. Additionally, the system's Easy Positioning feature allows components to be placed accurately and quickly on the board, while its Autopick program ensures that all components are picked up and placed accurately during assembly. CSM-200B and CSM-200C models offer a variety of features that make them ideal for high volume board production. For example, the 150-point placement accuracy unit and the vision camera ensure that all components are placed accurately, which helps minimize defects and reduce rejects. Additionally, the models are equipped with a high-speed pick-and-place head, which can pick up to 15 components per second, increasing the throughput of the machine. SONY CSM-200B and CSM-200C also provide advanced support for a variety of board materials, including FR-4 boards, copper-clad boards and flexible materials. Additionally, they are capable of processing a variety of device packages, including QFPs, BGA, and QFNs, making them suitable for applications requiring different levels of surface-mount complexity. To ensure reliable operation, CSM-200B and CSM-200C feature high-speed labeling device options. These include high-speed lasers that can quickly scan and mark components during assembly, reducing the risk of misplacement. The labeling devices also provide accurate marking of components on a variety of board materials, including both through-hole and surface-mount boards. SONY CSM-200B and CSM-200C models also feature multiple communication ports and direct connection to computers, allowing easy integration into industrial networks. This allows systems engineers to quickly setup and update custom production programs when needed. The models also feature a user-friendly graphical interface, allowing operators to quickly access and adjust settings and parameters as needed. In summary, CSM-200B and CSM-200C are versatile, high-performance PC board assembly and manufacturing systems. They feature advanced vision camera technology for better error detection, as well as a versatile set of features and support for a variety of materials, devices and labeling options. The models are also equipped with communication ports to facilitate integration into industrial networks, and a graphical interface to quickly change settings and parameters as needed.

There are no reviews yet