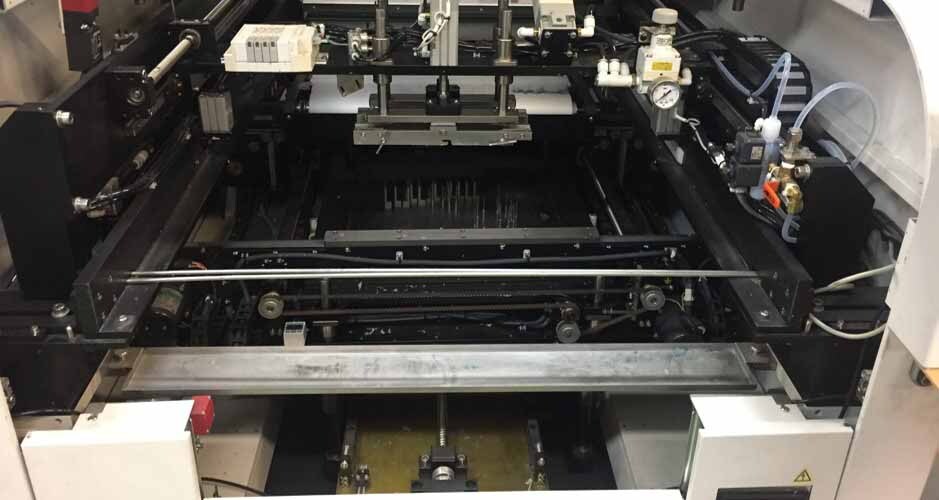

Used SONY SI-P850 #9184443 for sale

URL successfully copied!

Tap to zoom

ID: 9184443

Screen printer

PWB Size:

50mm x 50mm - 460mm x 410mm

PWB thickness: 0.4mm - 3.0mm

PWB Clearance: 900mm( -10mm - +45mm)

Print repeatability *1: ±15µm (3)

Cycle time*1: 10sec + printing time

Screen size:

W550mm x D650mm x H30mm or H40mm

W650mm x D550mm x H30mm or H40mm

W736mm x D736mm x H30mm or H40mm

Board position reference: Front or back

PWB fixing system:

Magnet system

Vacuum system

Support pin

Screen cleaning: Fully automatic roll or cloth type

OS: Windows 2000

Positioning: PWB end face

Back up support: Y-type profile clamp system

Operating temperature: 15-30°C

Power supply / Consumption*2: AC100V, 50/60Hz, 1.5kVA

Air supply / Consumption: 0.49MPa 430L/min.

SONY SI-P850 is an advanced PC board assembly and manufacturing equipment that brings together automation, control, intelligence, and precision technology for complex, high-quality production. It is designed for use in various industries, including aerospace, automotive, medical, and military applications, as well as industry and home use. The system consists of four individual modules: an input module, a placement module, a soldering module, and an output module. The input module, either an operator or robot, feeds individual sheets to the placement module, which then places and tracks components to exact locations on the board. These components are then soldered by the soldering module, either by hand, or using an automated soldering unit that is designed to produce consistent quality results. The output module is then responsible for inspecting the boards for consistent, high-quality soldering. The machine also features SONY patented Automatic Tool Calibration (ATC) tool. This asset automatically calibrates and maintains the registration of each component placement on the board, ensuring a consistently high-quality product. Additionally, SONY Intelligent Line Monitoring (ILM) model monitors the production line and assists in troubleshooting and preventative maintenance, helping to minimize downtime and ensuring optimal production. SI-P850 also features built-in safety functions to ensure the safety of all personnel working on the equipment. These safety functions are activated when the machine reaches a dangerous temperature or pressure level, which helps to prevent accidents in the work environment. Overall, SONY SI-P850 is a sophisticated and reliable PC board assembly and manufacturing system that offers a high level of safety, accuracy, and efficiency for large-scale board production. By utilizing advanced automation, control, and precision technologies, the unit can ensure optimal production outcomes and ensure consistent, high-quality results.

There are no reviews yet