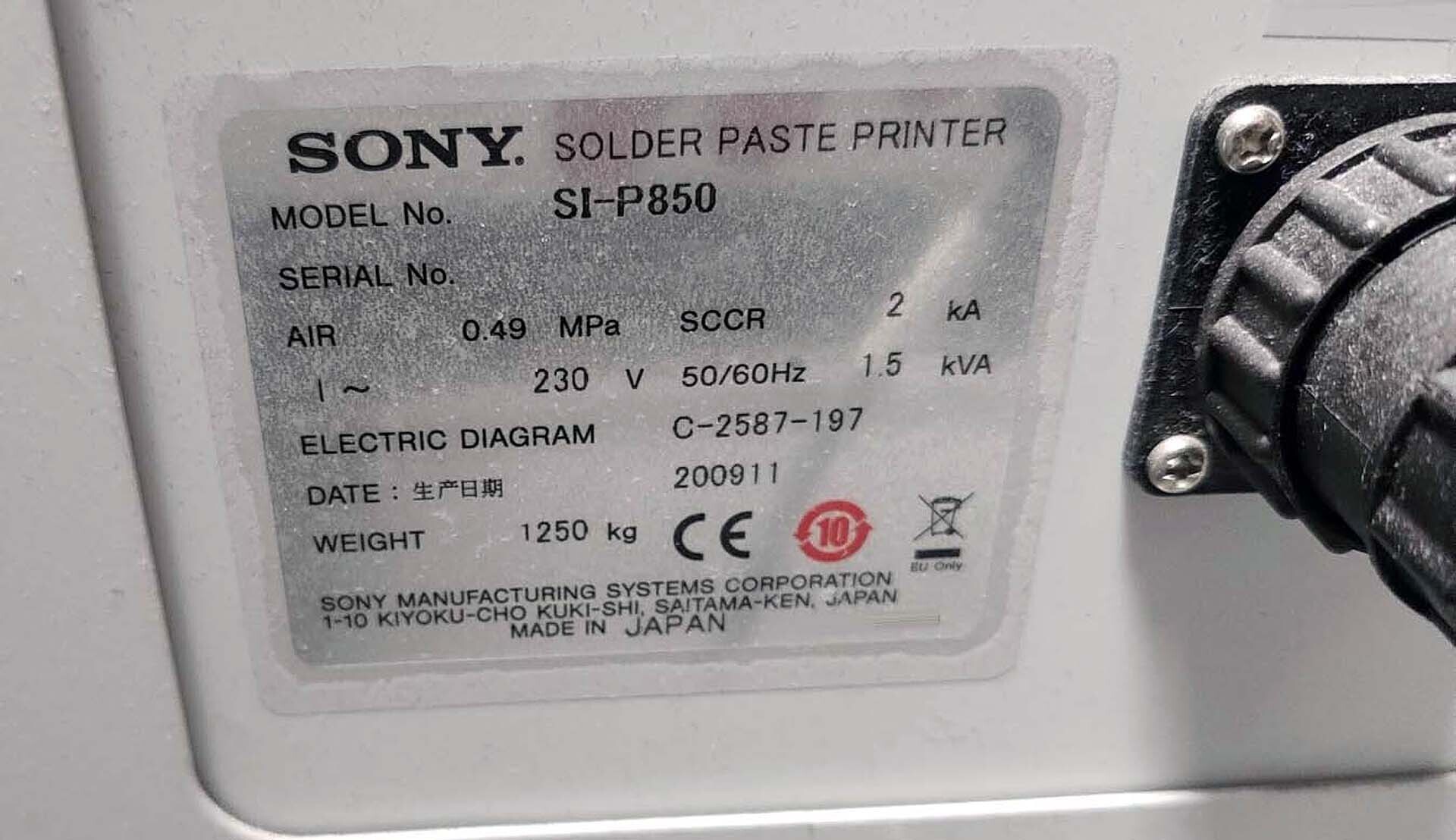

Used SONY SI-P850 #9301917 for sale

URL successfully copied!

Tap to zoom

SONY SI-P850 is a complete PC Board Assembly and Manufacturing equipment. This system features a high-speed two-sided adhesive application unit, a high-speed pick & place machine, an automated multi-function "flip chip" handling tool, and a precision component installation asset built into one automated platform. SI-P850 provides a versatile, cost-effective solution for a variety of industries including contract manufacturing, consumer electronics, medical device and industrial electronics. The two-sided adhesive application model on SONY SI-P850 is capable of finely adjusting the application thickness and maintaining its stability over time. This equipment is suitable for use with various substrates, from the most robust FR4 circuit boards to the most delicate Polyimide substrates. It is also capable of using various types of adhesives and is able to handle both large and small components, providing unique flexibility for different types of adhesive applications. With a combined application speed of up to 0.5W/cm2, SI-P850 proves to be one of the fastest two-sided adhesive application systems available. The pick & place system used on SONY SI-P850 is designed to handle both surface mount technology (SMT) and through-hole technology (THT) components, allowing for a wide range of applications. It employs position recognition and high-speed pick-up capabilities to drive performance in placement accuracy. The unit includes an automated X-Y table which can be used for multiple programs, and a built-in vision machine which can be used for placement corrections. The automation tool used for SI-P850 is built with 90 head rotation for easy switchover between different programs. The asset is also compatible with a variety of components, including leaded, lead-free, and non-leaded parts. The "flip chip" handling model of SONY SI-P850 is designed to handle highly precise components with advanced functionality. It utilizes a specifically designed vision equipment and registered chip alignment system to ensure that parts are correctly placed on the substrate. The unit also provides feedback on the quality of the installed components. With a combined speed rate of up to 10 chips per second, SI-P850 provides an efficient solution for the automated installation of small, intricate parts in a range of industries. The precision component installation machine used on SONY SI-P850 is capable of handling both surface mount and through-hole components with high accuracy and repeatability. It is designed to deliver accurate results with the help of an intelligent software package and a mechanical sub-tool. The asset is capable of handling a large variety of components, including both leaded and non-leaded parts. It is also capable of detecting components from different angles, allowing for a wide range of applications. SI-P850 is capable of handling components with up to 0.2mm accuracy and with a combined speed rate up to 3m/s. SONY SI-P850's complete PC Board Assembly and Manufacturing model is the ideal solution for many industries because of its unique combination of features. The two-sided adhesive application, pick & place, "flip chip" handling, and precision component installation systems all work together to provide efficient and cost effective solutions for a wide range of applications.

There are no reviews yet