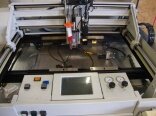

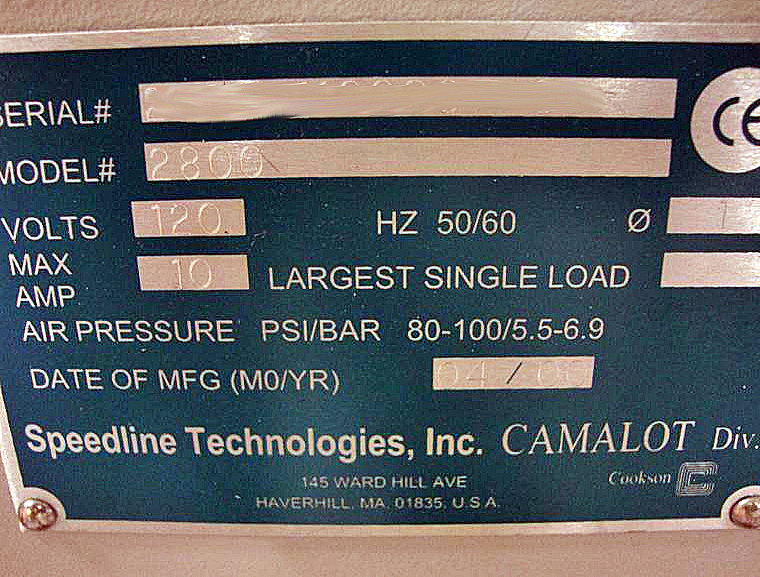

Used SPEEDLINE / CAMALOT 2800 #120947 for sale

URL successfully copied!

Tap to zoom

SPEEDLINE / CAMALOT 2800 is a versatile and efficient PC board assembly and manufacturing equipment, suitable for the mass production of precision electronics. It can reliably handle batches of up to 2,800 boards per hour, edging out potential competitors in terms of throughput and efficiency. The system provides lead-free soldering and automated component placement capabilities for a variety of PC board types, ranging from 2 to 5 layers thick. The component placement is incredibly precise and repeatable, and the unit is designed for operation with minimum time loss. Moreover, the component placement heads have easily adjustable placement heads which can rapidly shift from one place to another, reducing downtime significantly. To ensure maximum accuracy, the component placement heads feature Vision Centering technology and provide users with a live view of their workspace. This machine can concurrently inspect component placement locations, part orientations and component feeders in order to quickly detect any issues with component placement. For added safety, the tool has also incorporated a component collision prevention asset which reduces the risk of component contact damage. CAMALOT 2800 can solder surface mount components in the range of 0.5mm to 10.16mm, providing both high-quality solder joints and superior yields. The lead free soldering model has been optimized to increase the accuracy of navigational scanning and offers more flexibility when changing between different process requirements. Additionally, this equipment can be equipped with a nitrogen board pre-heat option which promotes long-term board stability in challenging environments. All parts of SPEEDLINE 2800 system are designed with simplicity, efficiency and convenience in mind. The unit is equipped with a graphical user interface which provides users with easy access to all relevant parameters and settings. Additionally, the machine, from loading and unloading components to switching between soldering recipes and performing diagnostics, can be fully adjusted to meet the user's requirements. 2800 is an all-in-one, fully automated PC board assembly tool that efficiently meets the industry's standard production requirements. This asset offers extraordinary throughput and accuracy and ensures maximum uptime, giving users the ability to produce high-quality, reliable components quickly and efficiently.

There are no reviews yet