Used SPEEDLINE / CAMALOT 3700 #130633 for sale

URL successfully copied!

Tap to zoom

ID: 130633

Vintage: 1999

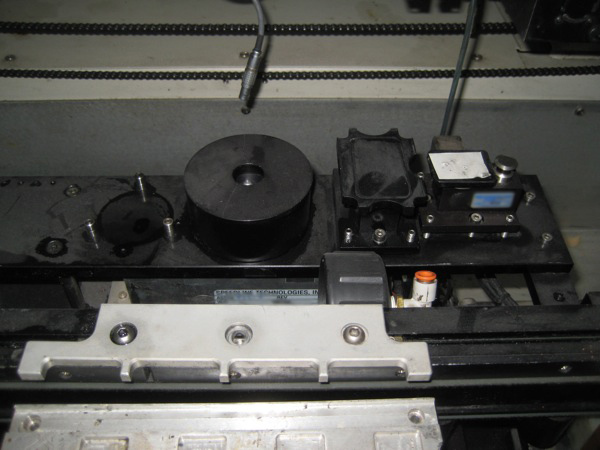

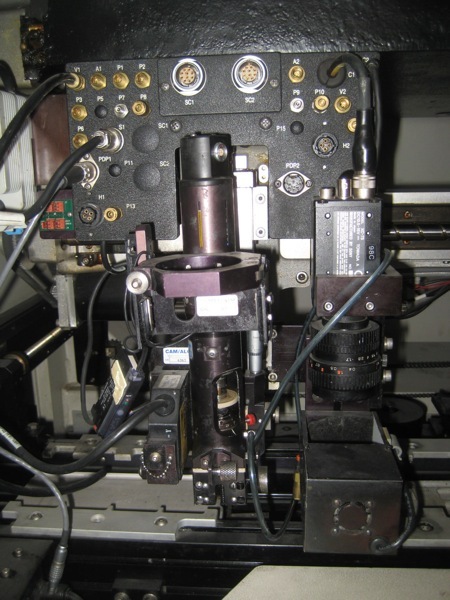

Underfill system with Speedline/Camalot pump

~30,600 hours

230V, 16A, 50/60Hz

1999 vintage.

SPEEDLINE / CAMALOT 3700 is a PC Board Assembly and Manufacturing Equipment that offers users a dependable and economical all-in-one solution for their printed circuit board manufacturing needs. This system is ideal for small and mid-sized businesses and is designed to deliver impeccable results while remaining energy-efficient and cost-effective. The unit is composed of a conveyor belt, board stacker, top-side camera and a head station. The conveyor belt is a high-speed machine that is able to transport printed circuit boards between the addressing, assembly and reflow phases at up to CAMALOT 3700 Inches per minute. The board stacker, provides reliable and error-free stacking capabilities for up to 25 printed circuit boards. The top-side camera offers an inspection height of up to 3-inch thick boards and can also detect leaded components down to .025 inch in size. The head station consists of an adjustable height board-to-post splitter, a placement head that can place up to 16 leads, and it's own camera for in-line checks and placement diagnostics. The placement head is capable of performing both x-y-z rotational and linear movement, allowing for precise placement of components. This tool also comes standard with various safety and quality assurance features, including laser calibration and optical verification systems, vacuum measuring systems, and automated optical inspection and diagnostic cameras. SPEEDLINE 3700 is a complete production solution with a robust choice of software and hardware capabilities. Its user interface is easy to use and the asset comes with comprehensive training materials on all its components and programming. The integrated diagnostic model continuously monitors performance and provides instant feedback on any errors that occur. The equipment also comes with an integrated quality control system that checks to ensure components are placed properly before completing assembly. This unit is also fully compatible with Automatic Test and Inspection (ATI) systems, such as Automatic Optical Inspection (AOI), Automatic Solder Paste Inspection (SPI), and Automatic X-Ray Inspection (AXI). It's also capable of soldering through-hole components, which can help improve process efficiency and reduce production costs. With 3700, production capacity is fully optimized with the capability of supporting up to seven concurrent feeders with multiple board sizes concurrently. SPEEDLINE / CAMALOT 3700 is an exceptionally cost-effective solution capable of producing superior results with fewer resources while minimizing waste and cost. With its user-friendly design, effective production capacity, and broad spectrum of functions, this PC Board Assembly and Manufacturing Machine can provide businesses with complete satisfaction.

There are no reviews yet