Used SPEEDLINE / CAMALOT 3700 #172454 for sale

URL successfully copied!

Tap to zoom

ID: 172454

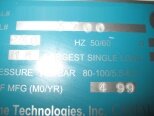

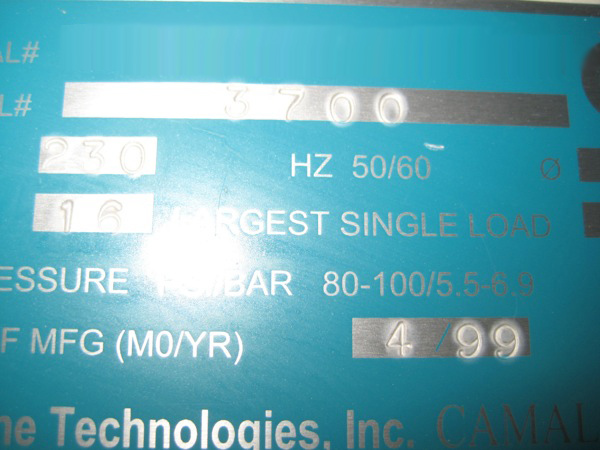

Vintage: 1999

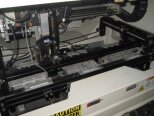

Underfill system with Speedline/Camalot pump

~15,563 hours

230V, 16A, 50/60Hz

1999 vintage.

SPEEDLINE / CAMALOT 3700 is a sophisticated pc board assembly and manufacturing equipment that offers a high-speed, cost-efficient solution for a wide variety of production needs. It features a compact, compact & modular control system, a fully automated unit with unlimited expandability, and a fast and dedicated motion control platform. The machine is composed of four hardware platforms: the host controller, the motion control unit, the chassis, and the accessories. The host controller is connected to an industrial PC used for programming and automation. The motion control unit controls the positioning of the production components and provides the controller with a vectorial model. The chassis houses up to eight lanes and provides rugged, stable and reliable support for the production components. The accessories provide additional expansion capability and functionality, which includes additional tooling, integrated tools, and additional software. CAMALOT 3700 has a powerful software suite that allows for easy programming and automation. Programming is done through Visual Basic and allows for complete customization of each production run. As the tool is highly automated, it eliminates manual set-up, ensuring increased production capability and accuracy. In addition, the software suite offers unique features such as virtual test control and online diagnostics. The asset is also highly flexible and the model can be easily integrated into existing production processes and systems. It allows for quick changeover and efficient production runs. Additionally, the equipment allows for custom configurations and expanded functionalities. It can also be connected to networked production systems, enabling the system to be integrated into larger production processes. SPEEDLINE 3700 is designed to produce products with high precision. Its software has built-in calibration functions and a "snap-in" unit that simplifies product placement and assembly. Its sophisticated vision machine allows for rapid and accurate identification of components, and its fault-tolerant technology ensures that all components in a production run are handled, processed and tested properly. The tool offers all these features and more in a compact, cost-effective platform that is ideal for those needing to quickly and efficiently produce PCB assemblies and other production requirements.

There are no reviews yet