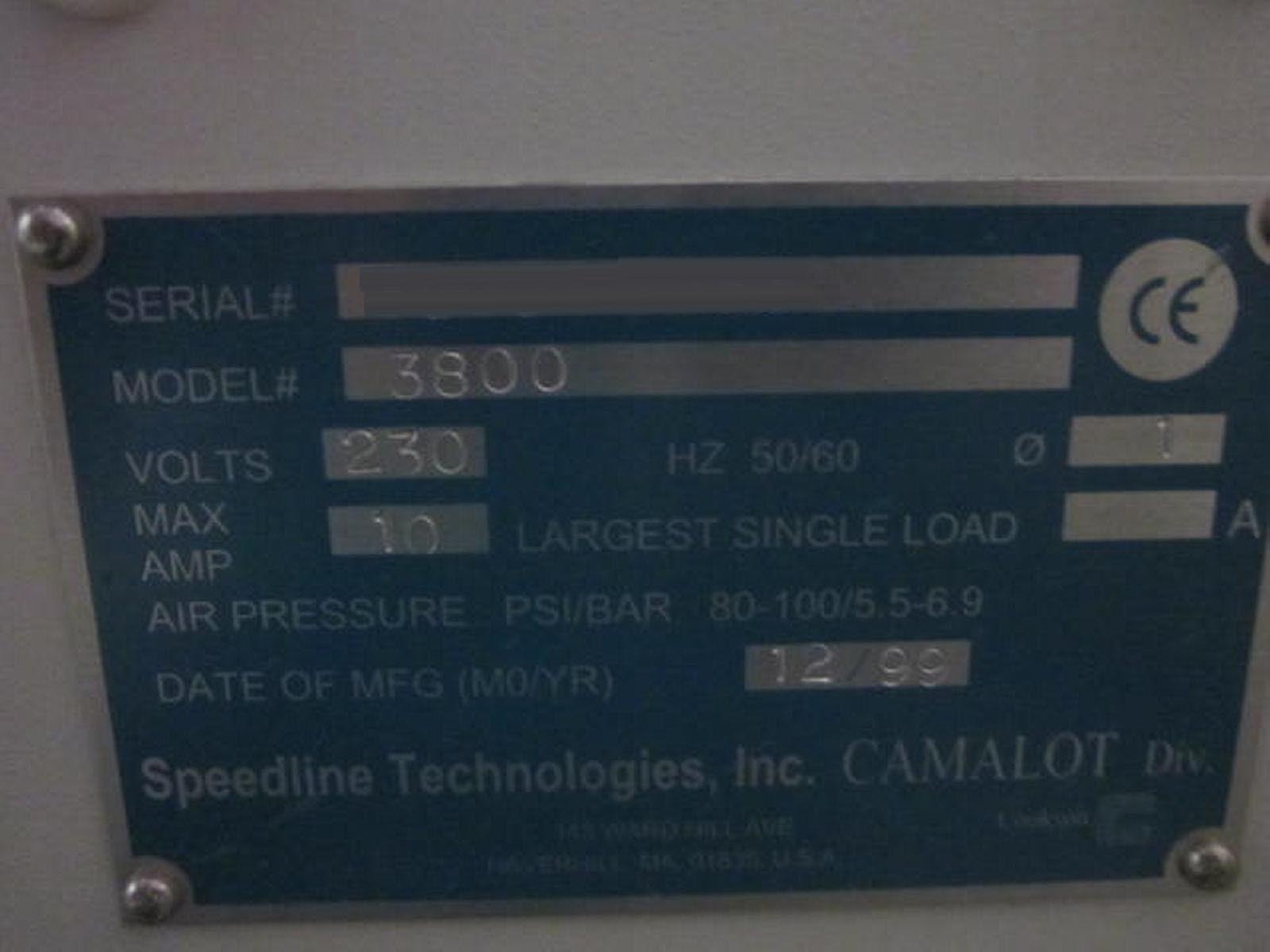

Used SPEEDLINE / CAMALOT 3800 #9093090 for sale

URL successfully copied!

Tap to zoom

ID: 9093090

Vintage: 1999

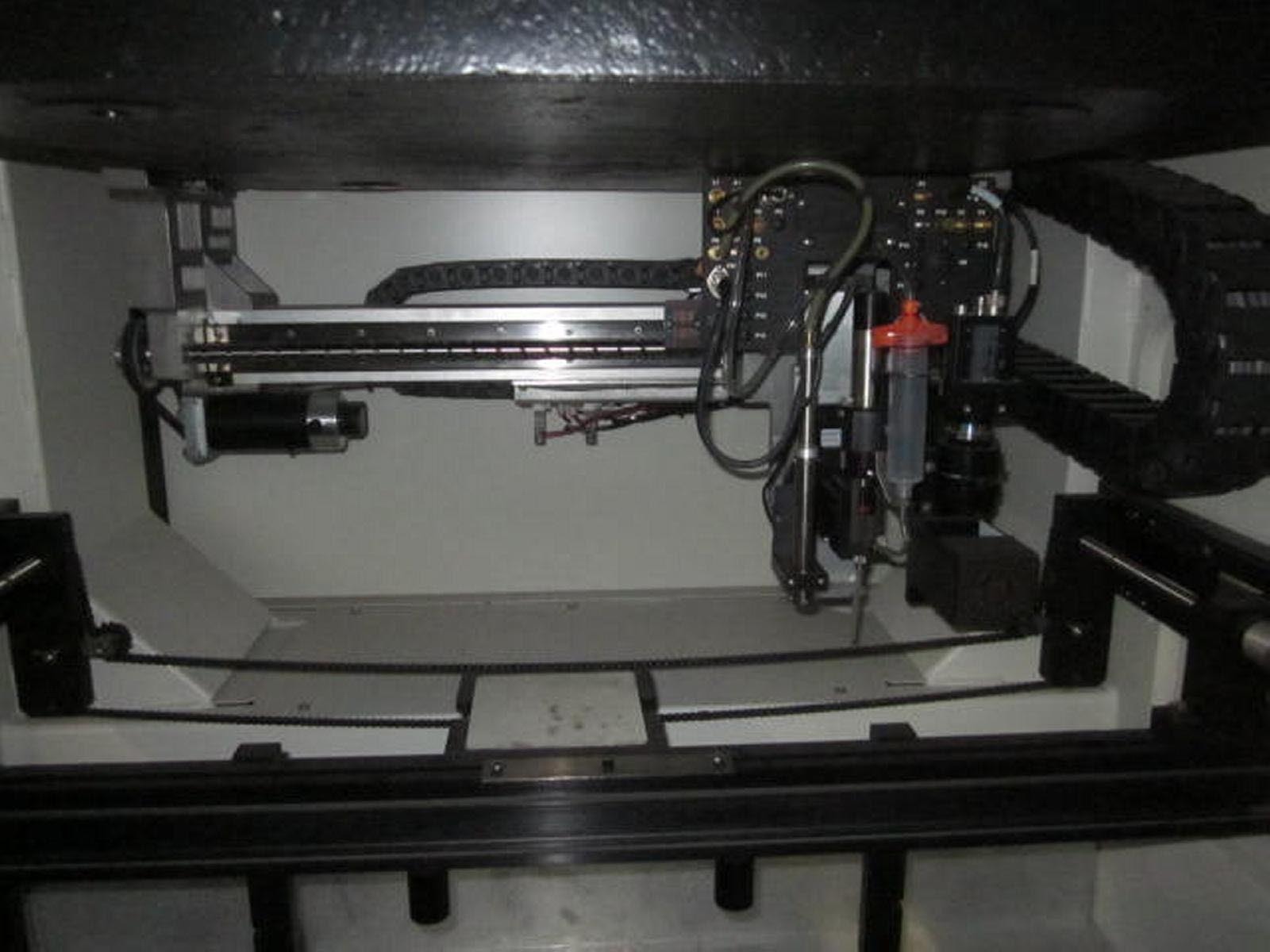

Linear bearing slides

Input/output zones (buffers)

Systems dispense up to 25,000 dots of solder paste or SMD epoxy per hour

Dispense area up to 19" x 19" for the 5000 and 14" x 14" for the 3800 system.

Hours: 14462

Displacement pump

Volts 230 Hz 50/60 Amp 10

1999 vintage.

SPEEDLINE / CAMALOT 3800 is a pc board assembly and manufacturing equipment specifically designed for rapid, high-accuracy assembly of printed circuit board (PCB) assemblies. The system is highly dependable and designed for use in a wide variety of industrial, automotive and consumer applications. With its heavy-duty components and innovative features, the unit is well-suited for long-term, trouble-free operation. The machine consists of a main cabinet containing a COSMOS Vision Elite machine control, CAMALOT Camera Kit, SPEEDLINE Cam Driver, PC camera mounting bracket, and mounting hardware. The camera is mounted above the dieboard and PCR (Printed Circuitry Release) and is used to locate parts on the board. SPEEDLINE / CAMALOT Software Suite provides a graphical interface to configure and customize the tool, along with a library of preprogrammed tooling opportunities and a wide range of production-ready settings. An additional optional CAMALOT Post Processor allows the machine to modify the tooling settings according to the customer's specific needs. SPEEDLINE asset utilizes advanced, high-speed robotic technology to accurately locate, insert, and press parts onto the PCB. The model can easily handle high-density, multi-layer PCBs, flexible circuits, single-sided boards, and circuits with multiple components. SPEEDLINE / CAMALOT software suite also offers a wide variety of decision-making capabilities, allowing the equipment to compensate for errors and deliver consistent high-quality results. The system also offers a wide range of customization options such as: adjustable speed settings, dynamic registration, quick reflow settings, pressure settings, feed speed settings, component placement and placement accuracy, and die size reduction. Additionally, CAMALOT unit can be integrated with external components such as barcode readers and temperature controllers via its Universal Interface. This allows for precise and reliable data transfer between the machine and external components, ensuring high-level accuracy and repeatability throughout the production process. Given its combination of innovative features and reliability, CAMALOT 3800 pc board assembly and manufacturing tool is an excellent choice for businesses looking for an efficient, dependable solution for their prototyping, production, and rapid prototyping tasks. Such features make it an ideal choice for automotive, consumer, and industrial applications that require high-accuracy, high-speed production.

There are no reviews yet