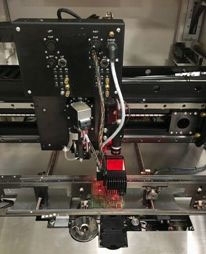

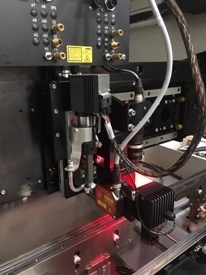

Used SPEEDLINE / CAMALOT FX-D #9261320 for sale

URL successfully copied!

Tap to zoom

ID: 9261320

Vintage: 2012

Dispenser

Model number: 8000-2

Working hours: 9922

635 Pump

Weight scale

Needle cleaner

Laser height sensor

Left to right pass thru conveyor

Dispense area: 20" x 23"

Auto width conveyor

Auto vision alignment

Vision system

Operating system: Windows XP

Includes:

PC

Monitor

Keyboard

Mouse

CE Marked

Power supply: 208-240 V, 50/60 Hz, Single Phase

2012 vintage.

SPEEDLINE / CAMALOT FX-D is a state-of-the-art automated equipment for PCB assembly and turnkey manufacturing. It features advanced process control, intuitive operator interface, and consistent placement accuracy. The system uses high-speed pick-and-place heads to mount components on double-sided or multi-layer printed circuit boards. Each head is fitted with an integrated vision unit to precisely locate components in relation to board slots and targets. The vision machine features a stringent part recognition capability, enabling rapid identification of single-sided or mixed-body components and placement on both sides of the board. The tool features digital operation, providing traceable and repeatable component placement and process performance. The computer-controlled design facilitates precise placement and movement of the pick-and-place tools, eliminating the need for manual programming and set-up. For a variety of boards, the asset is configurable for either flexible speed or thick-film placement, as well as alternate board sizes with minimal need for changeover. CAMALOT FX-D also offers a range of value-adding options such as automatic component presorting, barcode tracking, and component identification validation. The model is compatible with a wide range of stencils and components, including Surface-mount Technology (SMT), Through-hole Technology (THT), and mixed technology components. It is also equipped with an expansive library of CAD-compatible design components. SPEEDLINE FX-D is an ideal manufacturing solution for SMT assembly, PCB production, and rapid prototyping. Its superior component accuracy, ease-of-operation, and advanced vision equipment make it a superior choice for the most demanding board assembly requirements. This innovative system is the perfect solution for companies looking to streamline the PCB production process and reduce cost.

There are no reviews yet