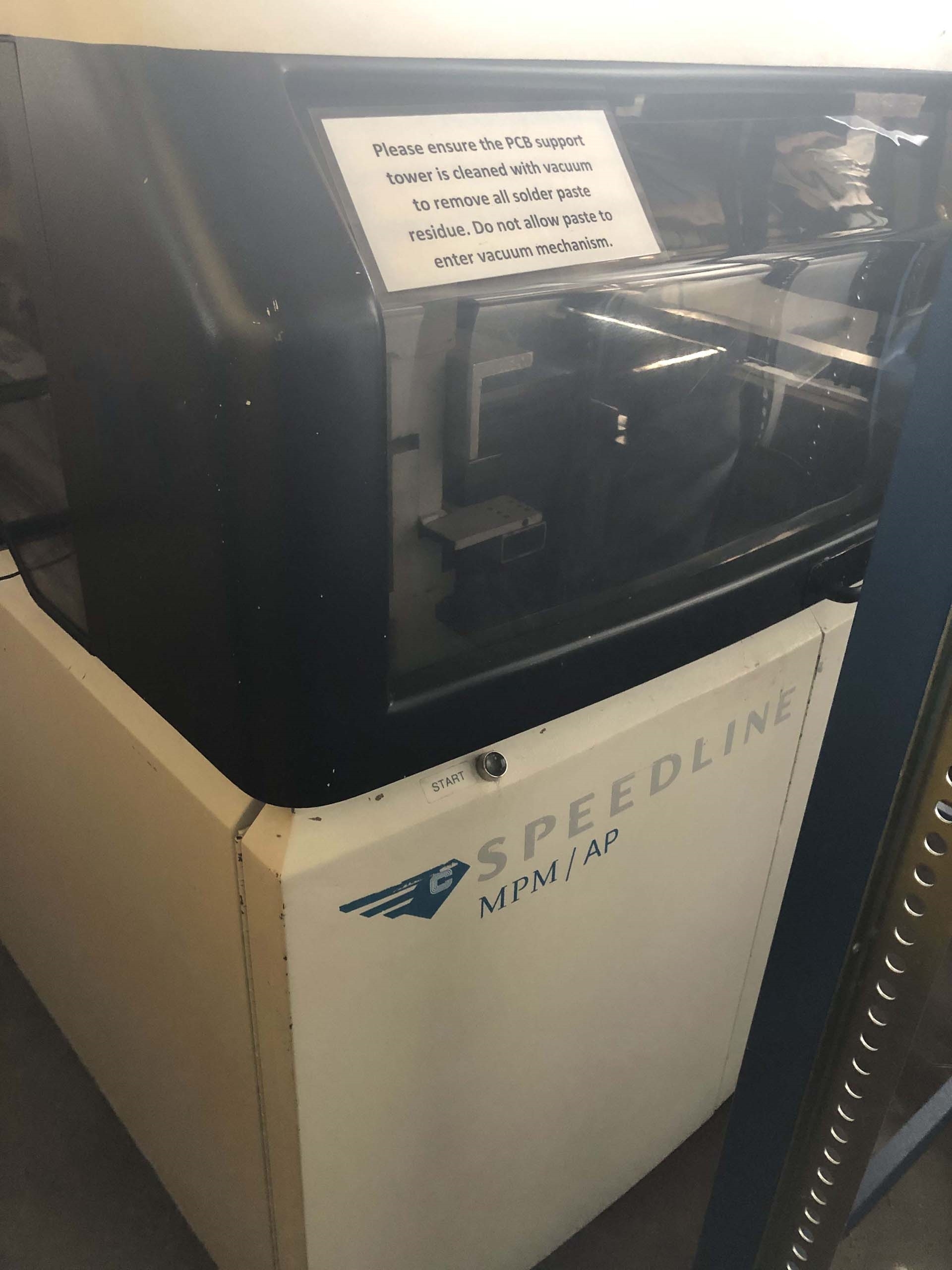

Used SPEEDLINE TECH MPM AP #9256139 for sale

URL successfully copied!

Tap to zoom

SPEEDLINE TECH SPEEDLINE TECH MPM AP is a highly versatile printed circuit board (PCB) assembly and manufacturing equipment, designed to provide efficient automated manufacturing solutions. This system consists of two basic processing units - an assembly platform and a motorized production platform (MPM). The assembly platform is an intelligent unit designed to manage the sequence of the assembly process, controlling the pick-and-place operation of components from the feeds. The programmable settings allow high flexibility of setup and operation, enabling custom configurations according to the requirements of a wide range of projects. Intelligent feedback systems ensure that assembly operations run at an optimal level, always yielding accurate and reliable results. The motorized production platform (MPM) adds an additional layer of automation to the machine, with state of the art motion control technology. It is capable of rapid, accurate placement of components, attaining speeds of up to 20,000 components per hour. Furthermore, with this tool, operators can develop, approve, and review component jobs in a matter of minutes. The asset is also equipped with a comprehensive user interface, which provides an intuitive model that anybody with an understanding of PCB manufacturing can use. Because of the amount of automation available on board, this equipment allows for a reduced time to market, rapid prototyping, and cost reduction of up to 40% per production run. It is also equipped with specialized Vision Software and Machine Positioning Software for accurate machine positioning, minimizing collisions and reducing set-up time. Safety measures have also been implemented to ensure that production processes maintain the highest levels of quality and safety while optimizing space and maximizing throughput. This system's wide range of features enable automation and organization of production processes for a range of projects,from small prototyping runs to large-scale production runs. By combining automation with on-board virtualization capabilities allows for reduced labor costs, improved production and inventory management, and high-volume performance. Its modern, efficient design and intelligent feedback systems make it an ideal component to any manufacturing unit.

There are no reviews yet