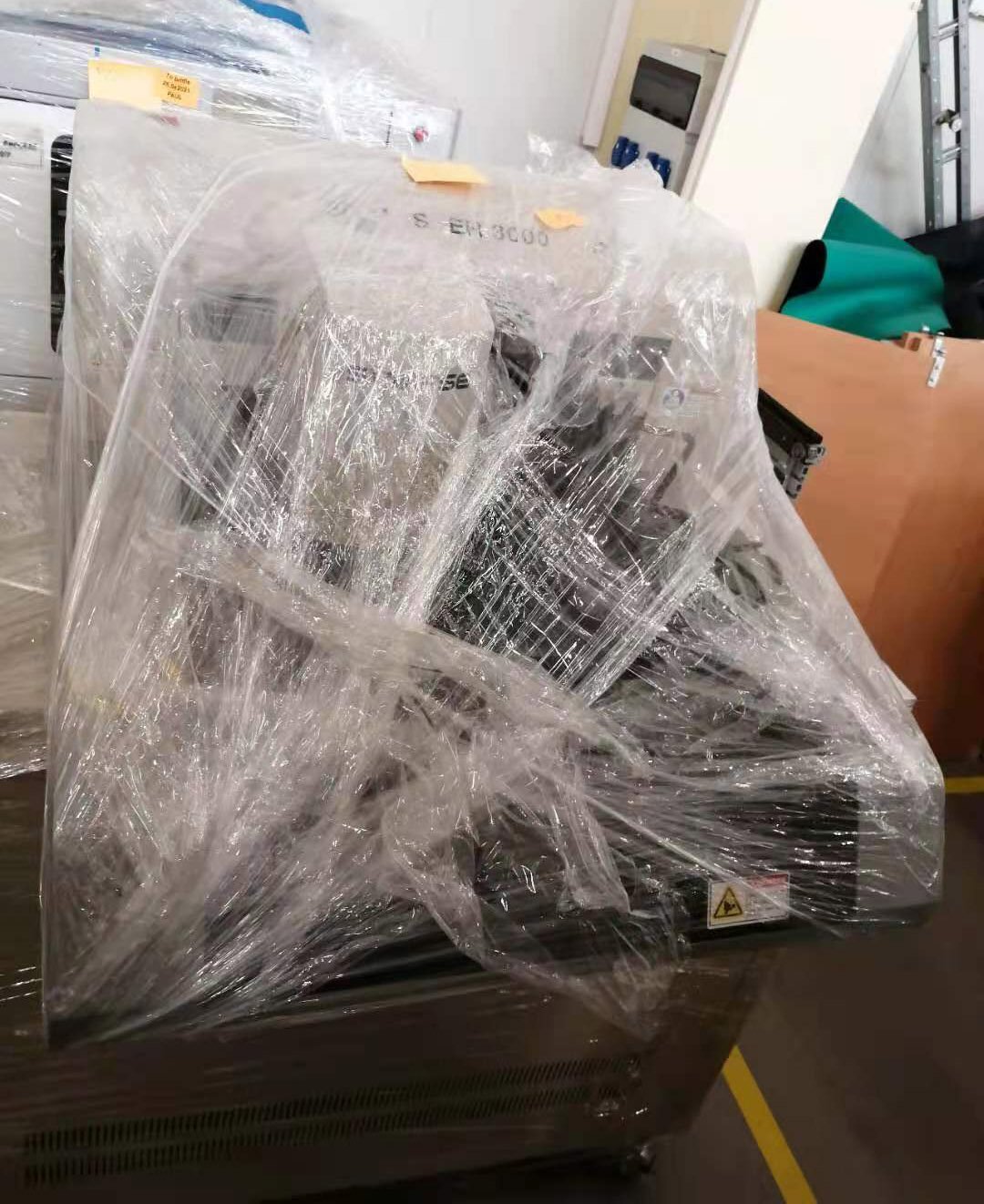

Used SYNAPSE IMAGING 3D MASTER 3000 Neo #9375514 for sale

URL successfully copied!

Tap to zoom

ID: 9375514

3D Solder Paste Inspection (SPI) system

Maximum PCB size: 510 mm x 460 mm

Power supply: 220 V, Single phase.

SYNAPSE IMAGING 3D MASTER 3000 Neo is a state-of-the-art 3D printed circuit board (PCB) assembly and manufacturing equipment. With advanced features such as an integrated LED camera system, a precision 3D printed circuit board inspection and repair unit, and a computer-controlled cutting and attachment process, the Neo has become a popular choice for PCB manufacturing. The LED camera machine offers a quick and easy inspection of the circuit board and components, with adjustable magnification to inspect any areas of concern. The integrated automated depth analysis and 3D contour imaging processes allow for a precise 3D image of the PCB to be taken and accurately measured. This data can be used to identify areas of concern and guide board repair, which can be done quickly and accurately with the advanced repair tool. The Neo asset also offers a computer-controlled cutting and attachment process. The user-friendly software provides a simple and fast way to cut and attach components to the PCB. This process is completed with precision and accuracy, ensuring that all the components are securely connected and perfectly fitted. Finally, the Neo comes with an integrated quality control model which scans the circuit board after assembly and performs a final evaluation. Any issues detected are flagged so the user can fix them immediately. This equipment helps to guarantee the highest quality products when leaving the factory. All in all, 3D MASTER 3000 Neo is an innovative and reliable system for PCB assembly and manufacturing. It offers precise and accurate results with each production run, making it an ideal choice for any electronics manufacturer. The integrated tools and quality control measures make the Neo a reliable and efficient unit for any PCB production needs.

There are no reviews yet