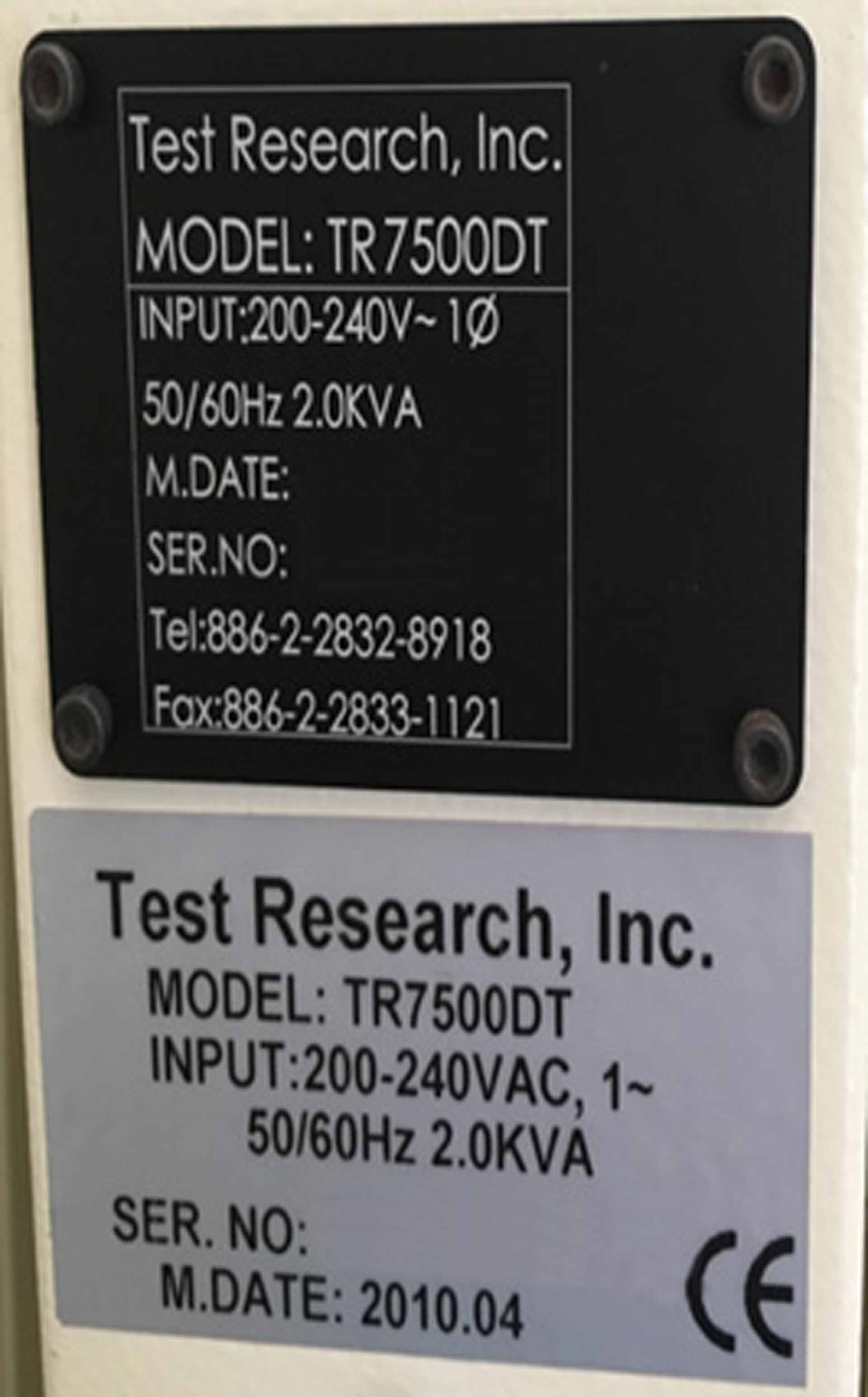

Used TRI TR 7500DT #9257870 for sale

URL successfully copied!

Tap to zoom

ID: 9257870

Vintage: 2010

Automated Optical Inspection (AOI) system

10 µm

2010 vintage.

TRI TR 7500DT PC Board Assembly and Manufacturing Equipment is a powerful and reliable automated production line that helps streamline and speed up the manufacturing process. The system enables quick and easy prototyping and assembly of printed circuit boards. For its assembly, the unit consists of a feeder, a board handler, and a desktop handling station. The board feeder unit loads up a PCB onto the board handler. The board handler then takes the board from the feeder and takes it to the desktop handling station. The handling station has four console ports that are designed to be compatible with a PC. From here, additional features can be implemented, including automated inspection, multiple component placement, testing, and automated dispense. The board handler is a robotic arm that quickly and precisely moves boards between the feeder and the desktop handling station. It is also designed to provide a secure and safe hold of the board at all times for increased accuracy and safety. The desktop handling station is designed to provide high accuracy during high-speed handling. It is also designed to ensure precise placement and reliable connection with other components on the board for increased accuracy and accuracy. The station is also designed to handle up to four boards at a time. The feeder, board handler, and desktop handling station are all integrated into one machine to provide a complete automated production process. TR 7500DT offers high throughput and increased reliability as for the production of high-quality printed circuit boards. It is a great solution for both small- to medium-scale production and prototyping and is suitable for many different applications. Overall, TRI TR 7500DT PC Board Assembly and Manufacturing Tool is a highly reliable and robust asset that offers a fast and accurate way of manufacturing printed circuit boards. It enables a quick and easy prototyping process and automated inspection, multiple component placement, testing, and automated dispensing. With its integrated technology, the model provides a streamlined and efficient production process and is an ideal choice for those looking to quickly and accurately produce printed circuit boards.

There are no reviews yet