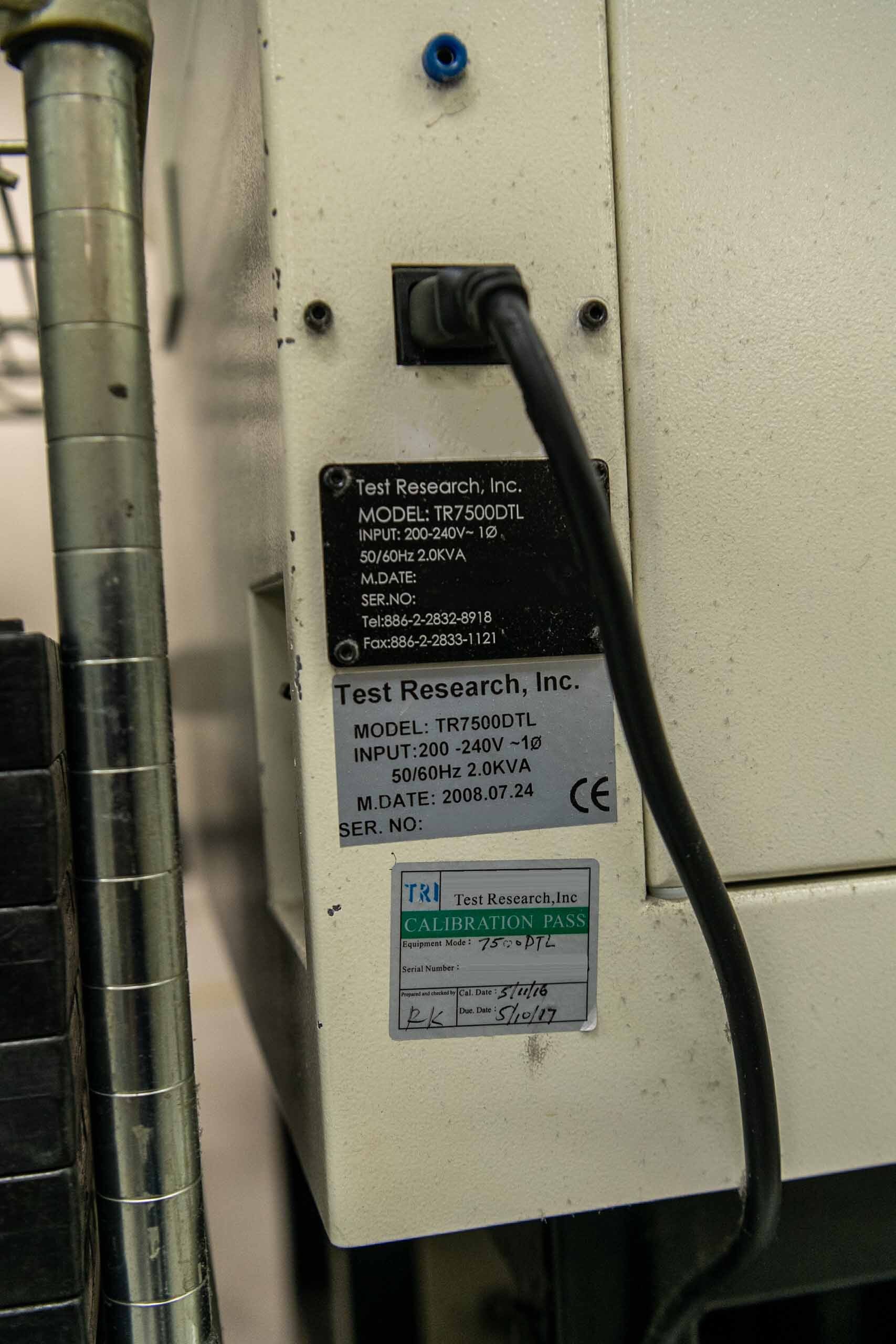

Used TRI TR 7500DTL #293616553 for sale

URL successfully copied!

Tap to zoom

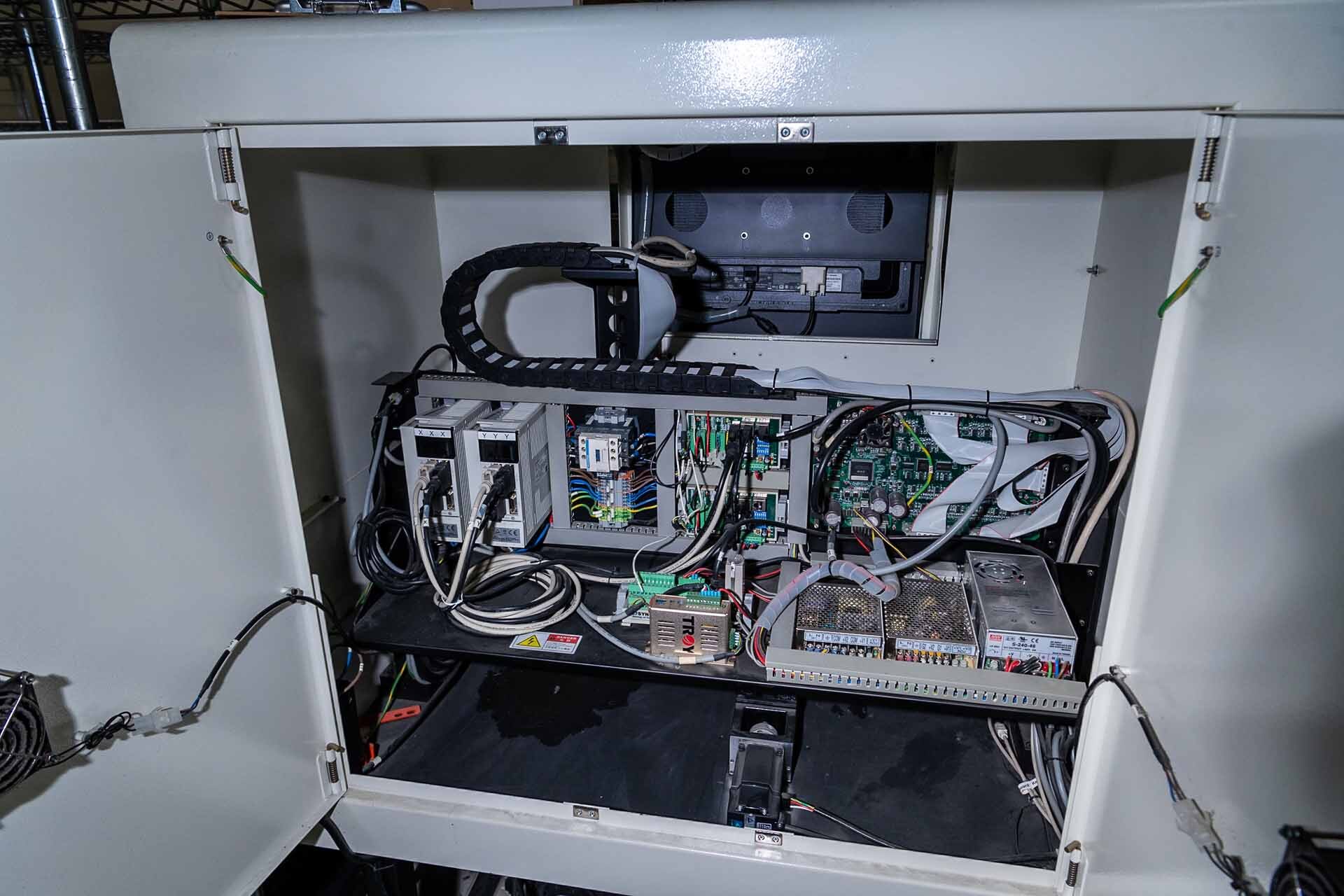

TRI TR 7500DTL is a pc board assembly and manufacturing equipment developed by TRintech. This PCBA manufacturing technology is designed for both short-run and high volume production runs. It combines a multi-layer substrate with a bulk of automated processes allowing rapid assembly and delivery of finely-detailed products. TR 7500DTL supports automatic double-sided SMT (surface mount technology) placement with precision dispensing. A feature packed system, TRI TR 7500DTL provides simultaneous processing of up to 12 layers of substrate material. It also ensures rapid feed of materials and components through the unit with high capacity gate ways and mass production lines with low unit-costs. A key feature of this machine is the integrated intelligent logging and traceability patterns for the parts and components to ensure foolproof production. TR 7500DTL also offers complete customizable control and fabrication. It provides variable data control from product to individual serial numbering and assembly of custom-defined machining or assembly techniques. Using Microsoft business intelligence, it gives the user complete control over the product layout, circuit optimization and machine settings using drag-and-drop or machine parameter adjustment. TRI TR 7500DTL also provides flexibility in load handling, optimized for high speed substrate processing and uniform terminals for board testing. The tool supports automated surface-mount soldering with solder jet technology, providing secure connection of components. An adjustable solder bath ensures perfect soldering of sensitive components in difficult-to-soldering environments. TR 7500DTL optional embedded asset maintenance software enables secure management of production runs and proactive tool life monitoring and repair. Additionally, TRI TR 7500DTL also offers the ability to robotically embed components into the substrates using adaptable programmed laser cutting. This ensures that high precision and repetitive performance is assured throughout the fabrication process, resulting in perfectly dimensioned products for uniform soldering and testing. Other features that contribute to greater throughput and efficiency are the intelligent closed loop feedback and job tracking. In conclusion, TR 7500DTL is a comprehensive PCBA manufacturing model designed for high-volume production with improved accuracy, reduced material costs, high flexibility and short run prototyping. With its range of automation, flexible control and tracking, this equipment offers great value and high productivity in large scale PCB assembly.

There are no reviews yet