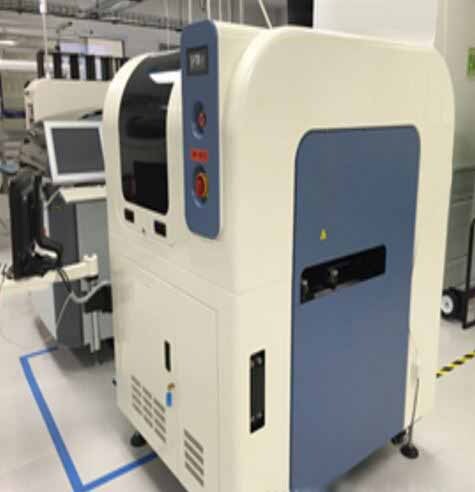

Used TRI TR7007 #9170311 for sale

URL successfully copied!

Tap to zoom

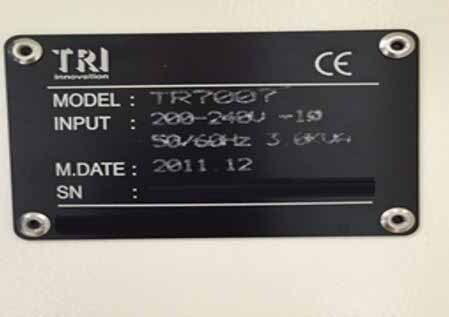

ID: 9170311

Vintage: 2011

Solder paste inspection system

Speeds of up to 160 cm²/sec

Ultra-Fast solder paste inspection

Hallmark features:

Closed loop function

Enhanced 2D imaging

Auto-warp compensation

Fringe pattern technology

High inspection speed up to 160 cm²/sec @ 14 µm

Shadow free fringe pattern lighting

Optical resolution 10 µm or 14 µm

Air requirement: BAR

Voltage: 200/240 Volts

Frequency: 50/60 Hertz

1 Phase

Current: 3 Amps

CE Marked

2011 vintage.

TRI TR7007 is a PC board assembly and manufacturing equipment developed by TRI Technologies. This modular system provides a comprehensive solution for fast and effective assembly of PC boards. It includes motorized spindles, high speed vision systems, component placement, pneumatics, and refining machines. The unit is made up of several components that complement each other for efficient and accurate assembly. The motorized spindles deliver precise and high speed rotating action that allow for quick component assembly. The high speed visual inspection machine includes a CCD camera for automatic recognition and positioning of components. This tool ensures that the correct components are placed in the designed positions. It can also sense soldering defects and check for other problems. Another key part of the asset is the component placement machines. This includes advanced servo motors for pick and place operations, coupled with a high speed nozzle and suckers. They help place components onto specific positions on the board. There is also a calibration model that provides precise positioning of components. The SAM refining machines are used for various tasks like pre-and post- hot air soldering, flux dispensing, wave soldering, and infrared soldering and vapor phase soldering. The flexible and powerful pneumatics equipment allows for powerful control of movements and placement of components with fine precision. This system can also program component coordinates and parameters to be used in iterative soldering operations. TR7007 is an all in one PC board assembly and manufacturing unit with various components for fast and accurate assembly. The motorized spindles, component placement machines, refining machines and pneumatics work in tandem to quickly assemble PC board components with high precision and accuracy. They also provide the necessary checks and safeguards to detect soldering inconsistencies. It is a great product for efficient and precise board assembly.

There are no reviews yet