Used UMG PLT-901-SH #9086580 for sale

URL successfully copied!

Tap to zoom

ID: 9086580

Vintage: 2008

Odd-Form Single-Head Bulk Pin Inserter

Insertion tooling for Automatic Assembly of Bulk Fed Pins

Single Inserter Head Assembly with Applicator Tooling

Single Terminal Feed Assembly and Rear Inventory Support

2.0, PLT-9010, X Y R Platform

5.0. PLT-9420, Machine guarding

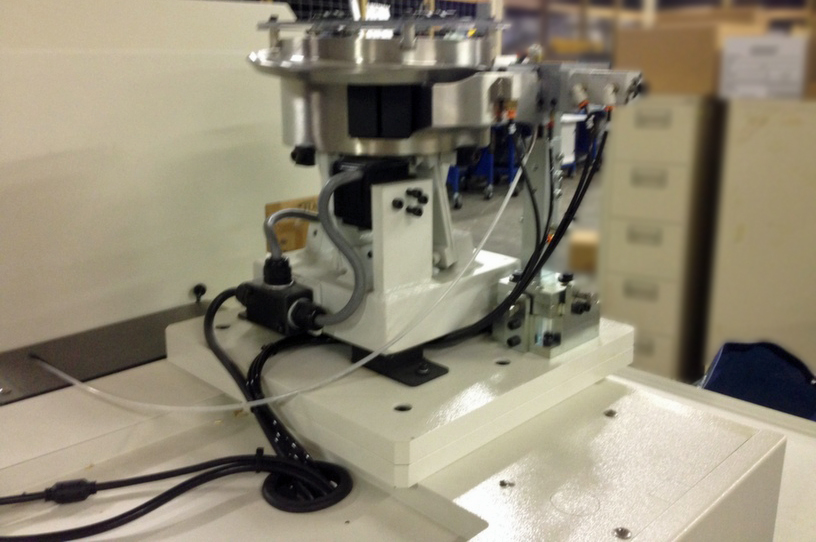

Bulk Fed Pin Insertion Head, Model MD-838

6" or 8" Stainless Vibratory Feeder bowl

Head Weldment Pinned and doweled for easy removal

Stroke adjustable applicator head for tight to PCB or Loose Fin Pin Insertion Process

Pneumatic Driven Insertion Head

Part Singulator

Component Centering Nest for Orientation Prior to Insert

Insert Shaft with Oil-Light Impregnated Bushing for Long Wear

Vibratory Bowl Mounting Weldment

Bowl Drive and Controller

Back Pressure Relief Built In

Air Blow Off as Needed for Incorrect Part Orientation

ESD Lexan Cover

Pin INsertion Speed Rated up to 9000 CPH

X Y R Platform

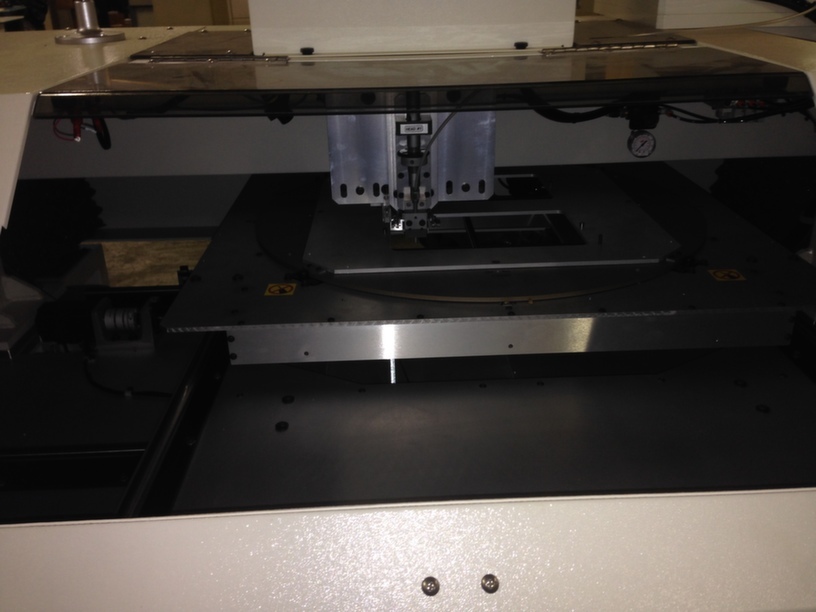

Single Table X Y position system

Gantry Weldment for Multiple Insertion Head Integration

High Speed Optical Correction

On Demand OCS Line Correction

On Demand Product Offset OCS Correction and Best Fit OCS Correction

ServoControlled X Y Table / Stage with an 18" x 18" insertion area and Bi-directional Rotary Table

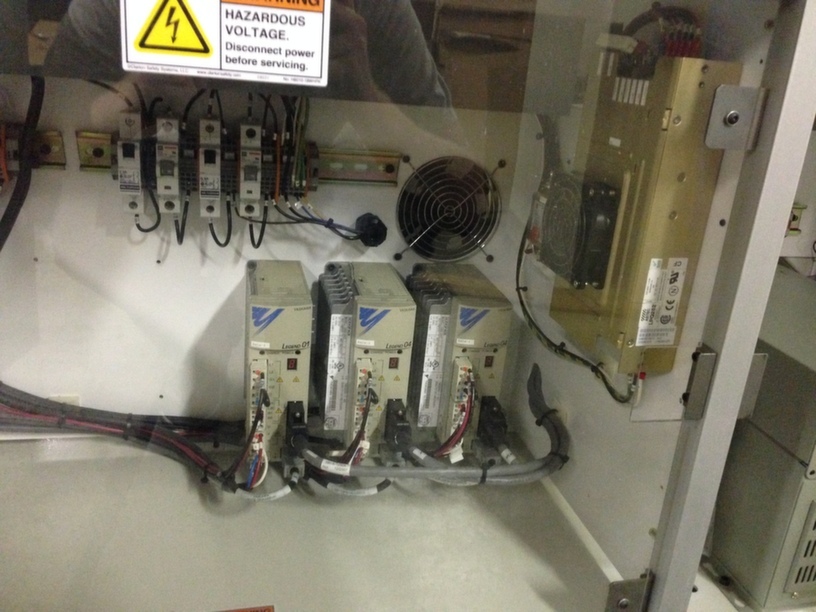

Yaskawa AC Brushless Servomotors and Servopack amplifiers

90º and 180º rotation per second

3-Axis positioning programming

Self diagnostic and comprehensive troubleshooting

Self calibrating with memory storage of factors

Insertion line Editor Software

Hours: <100

2008 vintage.

UMG PLT-901-SH pc board assembly and manufacturing equipment is designed for high-reliability and high-speed production. This system is capable of delivering up to 15,000 units per hour with minimal rework. It is designed for ease of use with features such as quick set-up for repeat manufacturing runs and on-screen job setup. The unit can be used for prototyping or low-volume products and high-volume production. PLT-901-SH includes a high-precision vision machine which is used to inspect and control the quality of each board assembly. The tool has the capability to apply over 100 processes depending on customer requirements to select components and verify their placement and orientation. The components are held in pockets of strips or tapes, which are placed into electrical feeder cassettes. The asset can accept 8mm and 12mm tapes, and strips and swagged connectors. A unique vision-alignment tool is used to ensure a precise and reliable model production. UMG PLT-901-SH has a built-in high-speed laser roughening and wave soldering equipment. This system can provide a wide variety of wave soldering capabilities including lead-free wave soldering, and it also has the capability to roughen pins or conductors to ensure that solder adheres to the components during wave soldering. PLT-901-SH is designed to deliver high-speed, high-accuracy performance and to minimize setup time. Features such as memory validation, laser roughening, and wave soldering capabilities, makes it easy for users to quickly adjust the unit for each production run, and it can also accommodate a wide range of components and sizes. The machine can be customized to meet customer needs, with optional accessories such as a Manual Insertion Tool, Partial and Full Pallet Loader, ESD-Safe Modules, and Vacuum Feeders. The asset also includes a suite of software tools which greatly simplifies setup, programming and operation. UMG PLT-901-SH pc board assembly and manufacturing model is intended for users who are looking for an efficient and reliable way to produce high-quality pc boards quickly and efficiently. With its precise vision alignment, high-speed solder, and roughening systems, PLT-901-SH equipment provides a comprehensive solution for efficient, high-quality production.

There are no reviews yet