Used UNIVERSAL 398 #9124783 for sale

URL successfully copied!

Tap to zoom

ID: 9124783

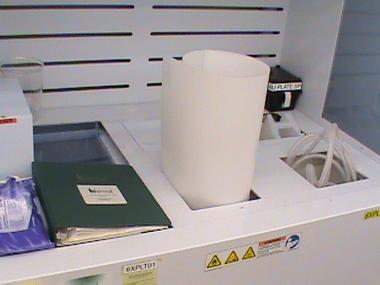

Wet bench, 4"

(1) Heated quartz plating tank

(1) Heated quartz tank

Dump rinse

Air and di gun

Parts missing.

UNIVERSAL 398 is a state-of-the-art pc board assembly and manufacturing equipment. It is designed to meet the demanding requirements of cleaning, inspecting, soldering and assembly of pc boards. The system is capable of production of complex and intricate pc boards, including multi-layer, thick-film, and flexi-rigid pc boards. The modular design of the unit allows for easy customization, and the ability to meet the exact needs of each customer. At the heart of 398 machine is a high-precision cleaning/inspection station. This station utilizes the latest technologies to clean each pc board, in order to ensure that all residues are removed prior to soldering. The integrated microscope and advanced imaging technology enable detection and correction of potential errors in the manufacturing process. The station is also equipped with automated depth and gap measurement tools to ensure that all components meet the highest engineering standards. The tool also includes a pair of welding stations for soldering. The stations use advanced laser soldering technology to provide accurate and precise soldering. The precise control of each station, combined with sophisticated heat control algorithms, enable the asset to manufacture pc boards with complex designs, without compromising reliability. There is also a range of welding accessories available, including soldering jigs and tips, to further ensure accurate welding. UNIVERSAL 398 model is also equipped with a highly advanced assembly station. This station uses automated pick-and-place technology to precisely assemble components onto the pc board. It is capable of assembling and fitting components with speeds of up to 20,000 parts per hour. It is also capable of sensing and correcting potential misalignment errors in the assembly process. Finally, the equipment is equipped with a complete set of testing and data gathering tools. This allows for the efficient characterization of each pc board produced, ensuring that all components meet the highest quality standards. Additionally, the testing station can also be used to monitor the quality of the soldering process, enabling the system to ensure consistent and reliable results. In conclusion, 398 is a state-of-the-art pc board assembly and manufacturing unit. With its advanced cleaning/inspection station, laser soldering technology, and automated pick-and-place assembly, the machine enables fast, efficient, and reliable production of complex and intricate pc boards.

There are no reviews yet