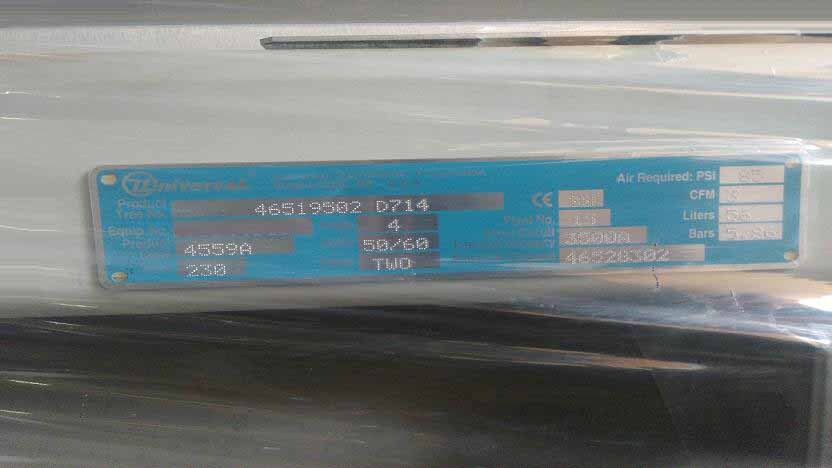

Used UNIVERSAL 4559A #9162264 for sale

URL successfully copied!

Tap to zoom

UNIVERSAL 4559A equipment is a fully integrated PC board assembly and manufacturing system designed to provide cost-effective, reliable solutions for medium and large volume production. 4559A unit is capable of working with integrated circuits (ICs), connectors, surface mount technology (SMT) components, and through hole technology components, as well as many other electronic components. The machine consists of an open architecture platform with a control tool that integrates media handling, component placement, solder reflow and component testing. UNIVERSAL 4559A asset uses a PC based operating model to manage the whole assembly process. This allows for customization of the production line with ease as well as the ability to integrate both existing and new control systems. The equipment has an in-line vision system that can detect component location and size, as well as an in-line temperature sensing unit to monitor the temperature of the components during the soldering process. To place components, 4559A machine uses a high-speed feeder carriage that is capable of delivering components up to 12 mm in size at a rate of up to 250 parts/min. This allows for high-volume production in a short period of time, ensuring that products are completed quickly. In addition, the feeder carriage can also be used to move components in and out of the solder processes station during manufacturing. UNIVERSAL 4559A also features an advanced reflow soldering tool that provides precision and consistency in soldering. This asset includes a conveyor belt with a temperature control model that can be programmed to maintain proper process temperatures for soldering, which helps to reduce defects and helps to increase yields. In addition, the reflow equipment can also be used to connect components together, making it a versatile solution for in-line assembly. Finally, 4559A system also includes several quality checking and testing stations. These include barcode readers, programmable scanners, x-ray inspection, and other systems to detect any defects or malfunctions in the components. This helps to ensure that any defects are caught during production and addressed quickly. Overall, UNIVERSAL 4559A unit is an efficient and cost-effective PC board assembly and manufacturing machine that provides a comprehensive solution for medium and large volume production. With its integrated control tool, high-speed feeders, reflow soldering, and advanced quality checking and testing stations, 4559A asset is capable of quickly and accurately producing quality products.

There are no reviews yet