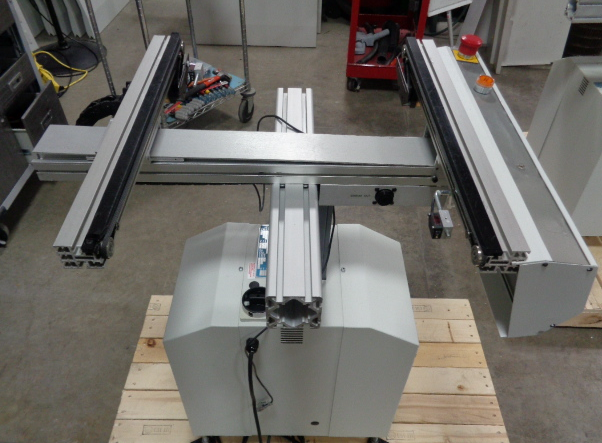

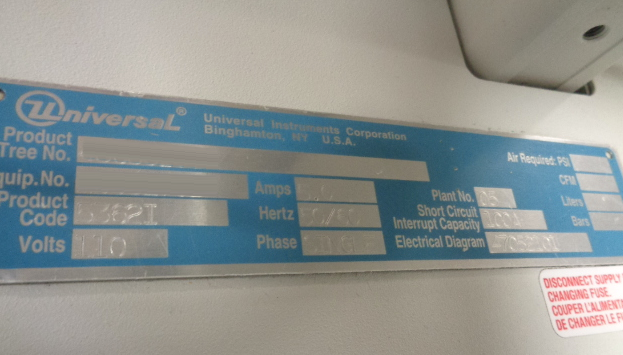

Used UNIVERSAL 5362i #9085955 for sale

URL successfully copied!

Tap to zoom

UNIVERSAL 5362i is a complete pc board assembly and manufacturing equipment designed to automate various production processes. It includes several components, including a workstation, conveyor, parallel loader, auto loader, two pick-and-place heads with vision alignment, and support devices. It is ideal for medium-to-large production runs and features precise production and detailed traceability. The system's functions provide complete manufacturing of pc boards from bare boards up to fully assembled, tested and labelled boards. 5362i has a large working area with two feeders with capacity of up to 1,000 parts, as well as a standalone oven. The unit also has up to three placement heads for offset error correction and two pick-and-place heads with vision alignment. The vision alignment allows it to determine the position and orientation of components by X-Y-Z axes. The machine features a high speed pick-and-place head with the capability to place both non-standard and large format components, and place packages up to 18x18mm. It also has a UNIVERSAL placement head for higher accuracy placement of components. The vision inspection tool is compatible with a variety of camera types, including 2D, 3D and Video cameras. It is also supported by high speed video inspection cameras to ensure consistent assembly and accurate inspection. In addition, the asset provides automatic cleaning for pc boards using detergent or solvent, and is able to select and mount different nozzles and components with automatic traceability. It also has an environmental monitoring model to measure the environment of the production area and further enhance the working environment. UNIVERSAL 5362i is a high-performance pc board assembly and manufacturing equipment designed to automate production efficiently and accurately. Its features include a workstation, conveyor, parallel loader, auto loader, and two pick-and-place heads with vision alignment, as well as complete traceability and inspection. It is capable of accurately placing a variety of components, including both standard and large-format components, with vision inspection to ensure consistent assembly and accurate inspection.

There are no reviews yet