Used UNIVERSAL 6241B #165956 for sale

URL successfully copied!

Tap to zoom

ID: 165956

Vintage: 1998

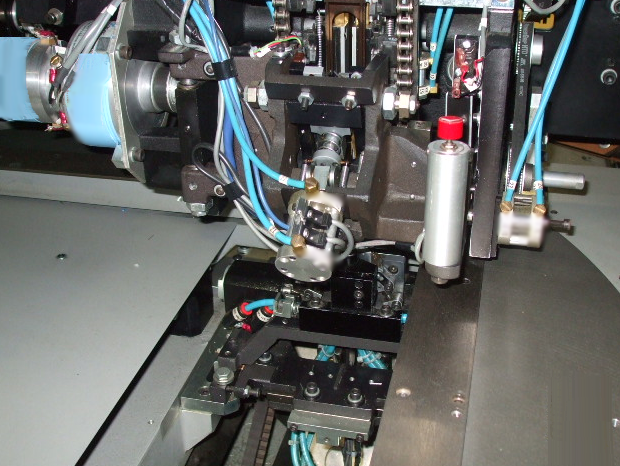

Axial sequencer 5

13.7 million cycles

60 Input stations

Latest rev Dispenser heads "F" style

full refire system on sequencer

Stand alone cover package

ERV Expanded Range Verifier

1998 vintage.

UNIVERSAL 6241B PC board assembly and manufacturing equipment is a powerful and reliable solution for creating small to medium-sized electronic circuits. This system provides excellent reliability, flexibility and performance while simplifying the production of small-scale circuit boards. It is the ideal solution for prototyping and high-volume production runs. The basic unit is composed of a main control console and multiple module cards that can be swapped in and out as needed. The main control console contains the processing and logic to initiate, control and monitor the operation of the machine. There are two main types of modules, component feeders and component placement heads. The component feeders are used to store and convey parts to the component placement heads. The component placement heads are motorized, robotic arms that guide components to their precise location on the circuit board. The component placement heads can be configured to accurately handle a variety of component sizes and shapes. 6241B also includes high-precision component testing capabilities. This tool includes an optically-based component test asset that uses a laser to measure components' electrical characteristics. The component test model also includes a digital monitoring component that can be used to monitor the process and provide real-time feedback on component quality. UNIVERSAL 6241B also includes automated tooling. This includes a press fit tool, a soldering chin, a reflow oven, and a tool that measures component locations. All of these tools are automatically controlled by the main control console, allowing the operator to quickly and accurately produce PCBs. The tooling is designed for quick and easy changeover, allowing users to switch between different components quickly and accurately. Overall, 6241B is an excellent solution for producing small to medium-sized, production-ready PCBs. This equipment provides excellent flexibility, control and accuracy, allowing users to quickly and accurately produce quality PCBs. This system also offers automated tooling and component testing capabilities, allowing users to rapidly test, debug and deploy their circuit boards. UNIVERSAL 6241B is a valuable solution for any production that needs automated, high-precision PCB assembly.

There are no reviews yet