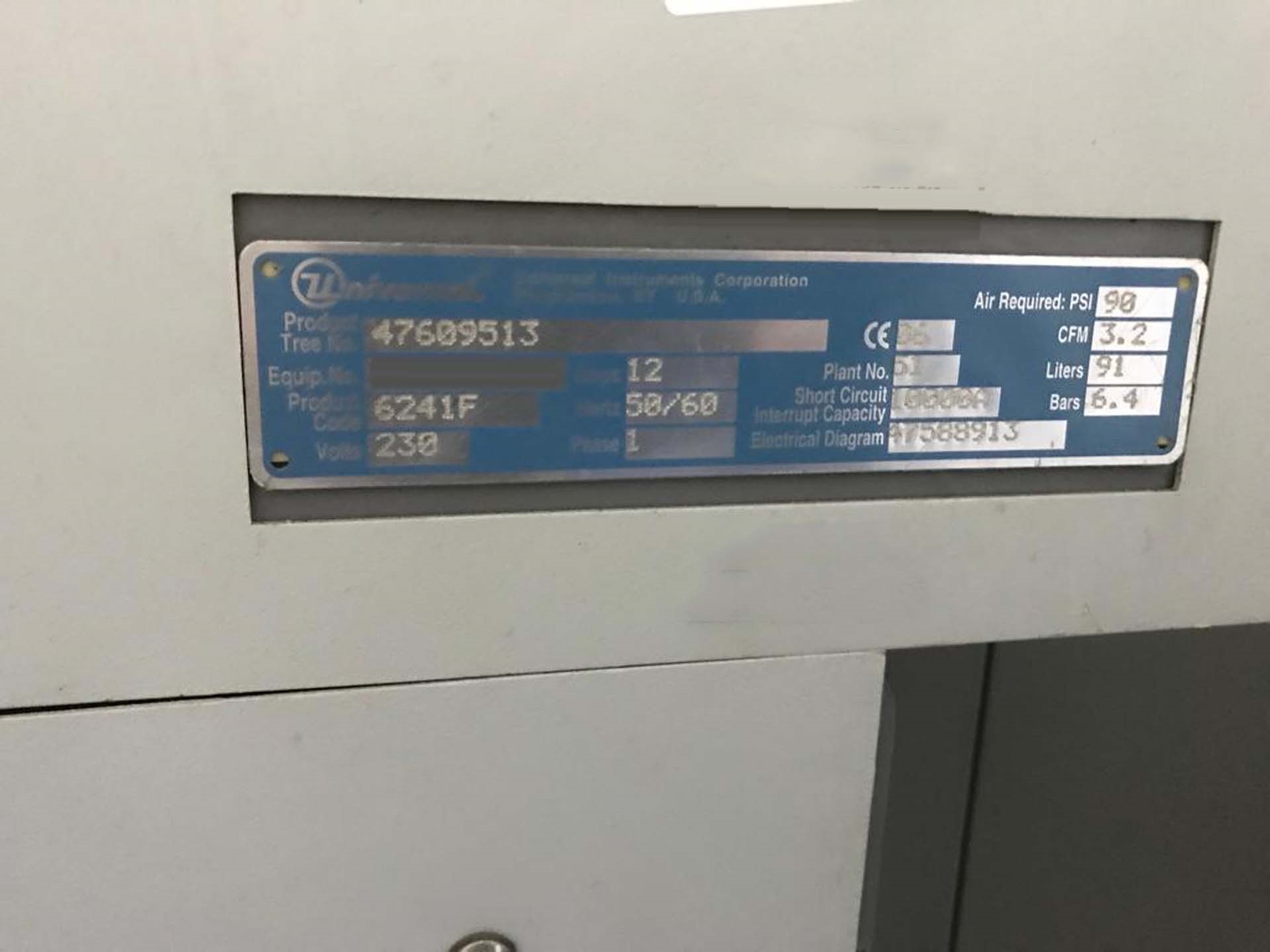

Used UNIVERSAL 6241F #9227436 for sale

URL successfully copied!

Tap to zoom

UNIVERSAL 6241F is a high-performance PC board assembly and manufacturing equipment that is designed to automate the tasks of component placement, soldering, testing, and rework of multi-layer boards. The system is made up of a base cabinet that houses the main components, including the unit operating electronics, a feeder head assembly for rapid component placement, and a moving arm assembly for soldering on the components. The machine has a vision tool that can detect component and soldering locations and can detect faults such as misalignment, missing components, and defects. In addition, the asset has multiple soldering heads and can be used for both leadless (e.g. BGA and QFN) components and through-hole components. 6241F is designed to be flexible and can be easily customized to fit your specific manufacturing needs. This is accomplished through a modular model architecture that allows for easier and faster installation and modification of the equipment components and settings. It can also be integrated with a wide range of test equipment and robotics systems for improved quality control and increased throughput. The system can be used for a variety of applications, including high-speed manufacturing, low-volume manufacturing, prototyping, rework, test and repair. In terms of technical specifications, the unit includes a single-axis robotic arm with a reach of 665mm, as well as a dual-rail gantry machine with a reach of 560mm. It has an integrated vision tool with an 8-mega pixel camera that can detect components and detect soldering points accurately. The soldering asset has a single-zone infrared preheater and multiple soldering heads that can handle both leadless and through-hole components. The model is equipped with a high-quality, automated programming interface that can be used to easily create and edit programs for component placement and soldering applications. In addition to the features mentioned above, UNIVERSAL 6241F also has features such as an operator control terminal that allows for easy operation and program editing. The equipment also has multiple optional features such as a jig holder and conveyor assembly for component loading, an automated stencil printing system for solder paste application, and an exhaust unit for capturing lead tin plating exhaust. The versatile machine offers excellent reliability and stability, as well as enhanced speed and accuracy. The tool is ideal for high-volume PCB manufacturing and it offers a number of advantages for those engaged in PCB assembly and manufacturing.

There are no reviews yet