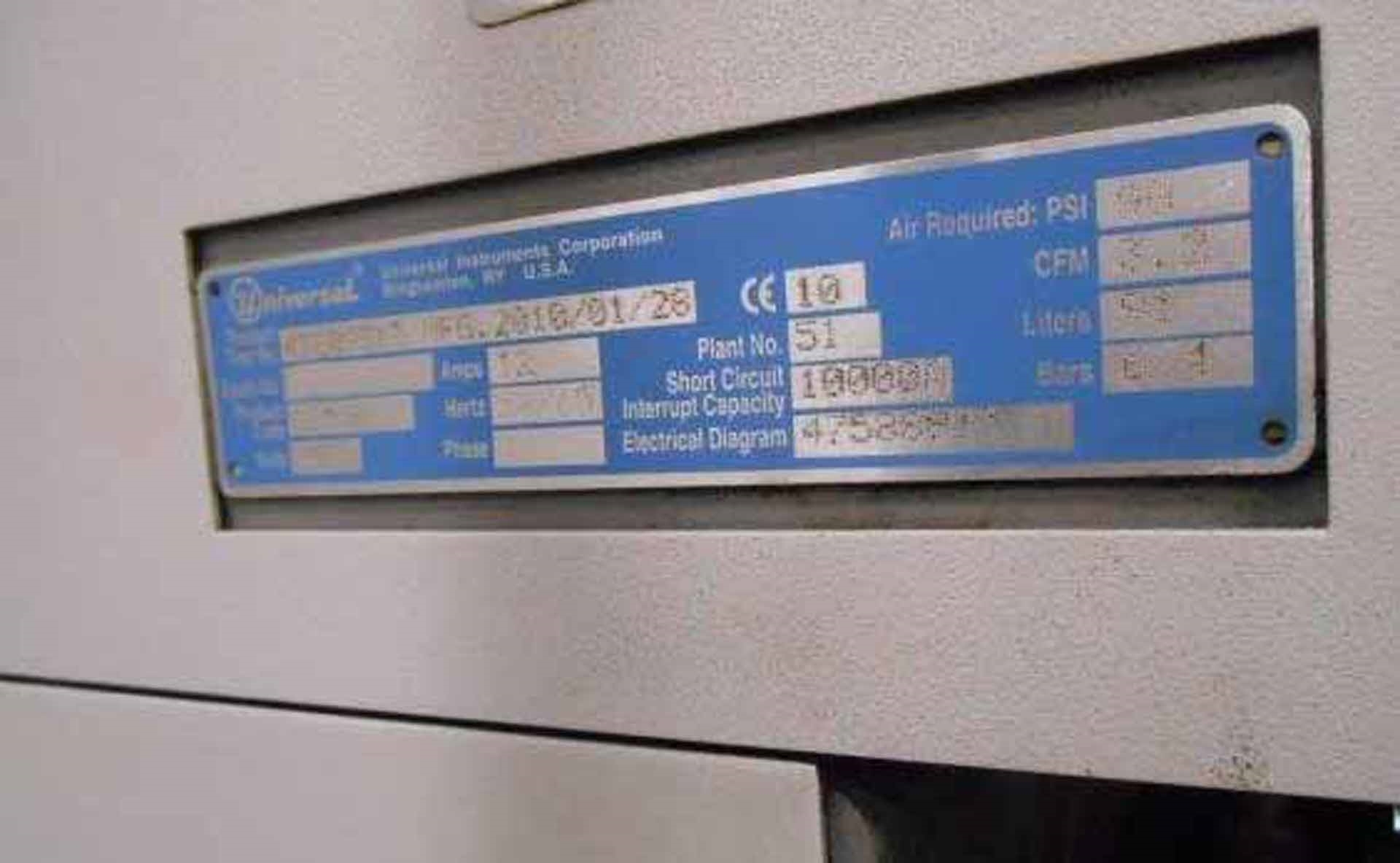

Used UNIVERSAL 6241F #9258352 for sale

URL successfully copied!

Tap to zoom

The UNIVERL UNIVERSAL 6241F PC Board Assembly and Manufacturing Equipment is a comprehensive, automated processing solution for the manufacturing of printed circuit boards. It provides a highly efficient, accurate, and cost-effective method of delivering a high quality of service and end product. The system is designed to use a single-sided substrate and can handle a variety of substrates such as FR-4, polyimide, and RoHS compliant PCBs. This allows for greater flexibility in the production process and improved efficiency. The UNIVERL 6241F also includes a variety of additional automation features, including: 1. Centering Stage - This stage allows for precise alignment of components on the substrate for a more reliable assembly. 2. Adjustable Head Stage - This stage provides a precise method of controlling head heights and speeds in order to achieve a higher quality end result. 3. Staged Assembly Process - This process can be divided into four stages: seed preparation, component placement, re-flow oven, and soldering. 4. Component Feeders - The unit is able to handle a variety of component feeders in order to efficiently feed components to the substrate for easy and reliable placement. 5. Offline Programmable Sequencing - This feature allows for the machine to be programmed for efficient repetition of specific processes. 6. ESD Protection - The tool includes a number of ESD features in order to ensure a high level of protection for components and operators. The UNIVERL UNIVERSAL 6241F is capable of handling a variety of substrates in different sizes, shapes and thicknesses. It is also designed for compatibility with most standard testing fixtures, meaning designers have greater freedom in their design process. The asset is capable of producing top-end quality printed circuit boards in quick and cost-effective manner, all while providing excellent levels of safety for operators.

There are no reviews yet