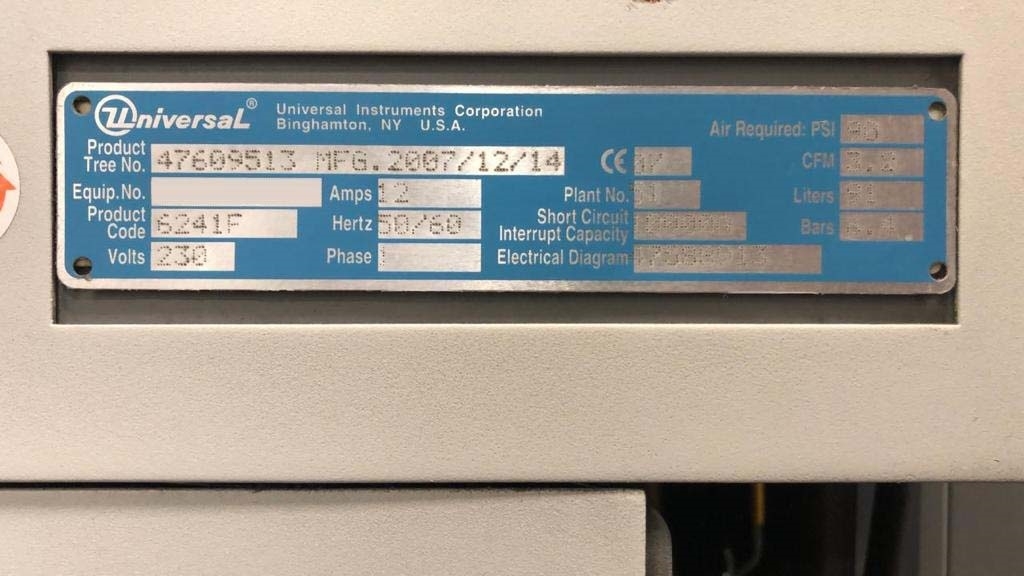

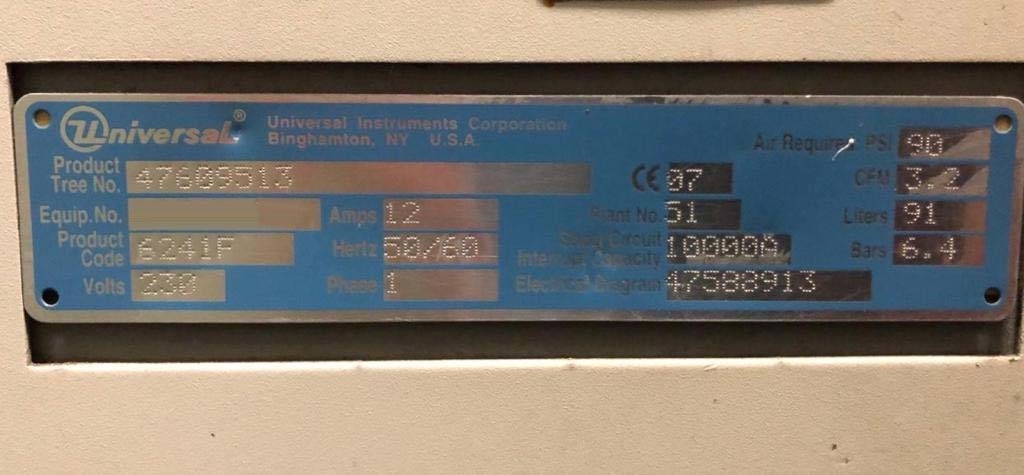

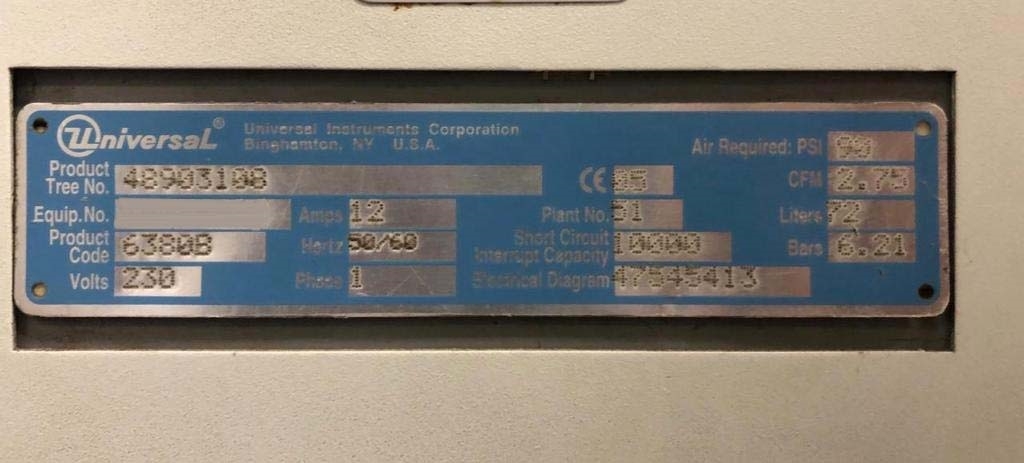

Used UNIVERSAL 6380B #9258355 for sale

URL successfully copied!

Tap to zoom

ID: 9258355

Vintage: 2010

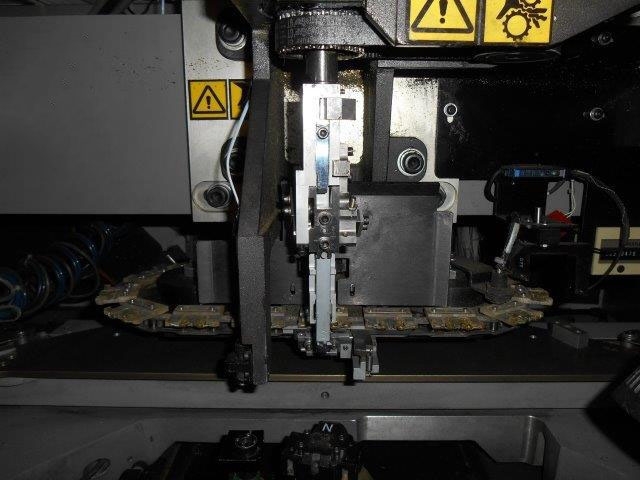

Radial inserter

Model: TXT

Spare parts included

2010 vintage.

UNIVERSAL 6380B is a versatile, fully automated pc board assembly and manufacturing equipment designed to streamline production processes and reduce costs. It is a modular system that can be configured to fit various production needs and is designed to be reliable, efficient, and cost effective. At the heart of the unit is an Intelligent Feeder Management Machine (IFMS) that is specifically designed to handle a variety of feeders for different feeder types in an efficient manner. IFMS reduces feeder downtime and enables reliable, repeatable performance of the assembly tool. The feeders onboard the asset are tailored to securely and precisely position components, even for large boards. The placement heads used by the model are also extremely accurate. The combination of an advanced vision equipment and a state-of-the-art camera system allows for both flexible and repeatable high-speed placements with a placement accuracy of 3 mils or better. It is also equipped with a 3-speed recalibration option to accommodate the varying board sizes and angles that may be encountered while processing a single board. 6380B also provides excellent quality control capabilities. Through its built-in high-speed image acquisition and its vision unit, the machine is able to detect missing or misplaced components, as well as misaligned pin connections. This ensures that only defect-free boards enter the downstream operations. UNIVERSAL 6380B is a compact tool, designed to occupy minimal workspace. Its small size allows for easy installation and integration into most production lines. It is also designed with easy maintenance and simple service in mind. This ensures that the asset won't get bogged down over time, allowing production to remain consistent and efficient. In short, 6380B pc board assembly and manufacturing model is an optimized solution to streamline production processes and reduce costs. With its efficient feeder management equipment, highly precise placement heads, and excellent quality control capabilities, the solution provides consistent and reliable assembly performance. Its small size, easy maintenance program, and simple serviceability make it an ideal choice for any production environment.

There are no reviews yet