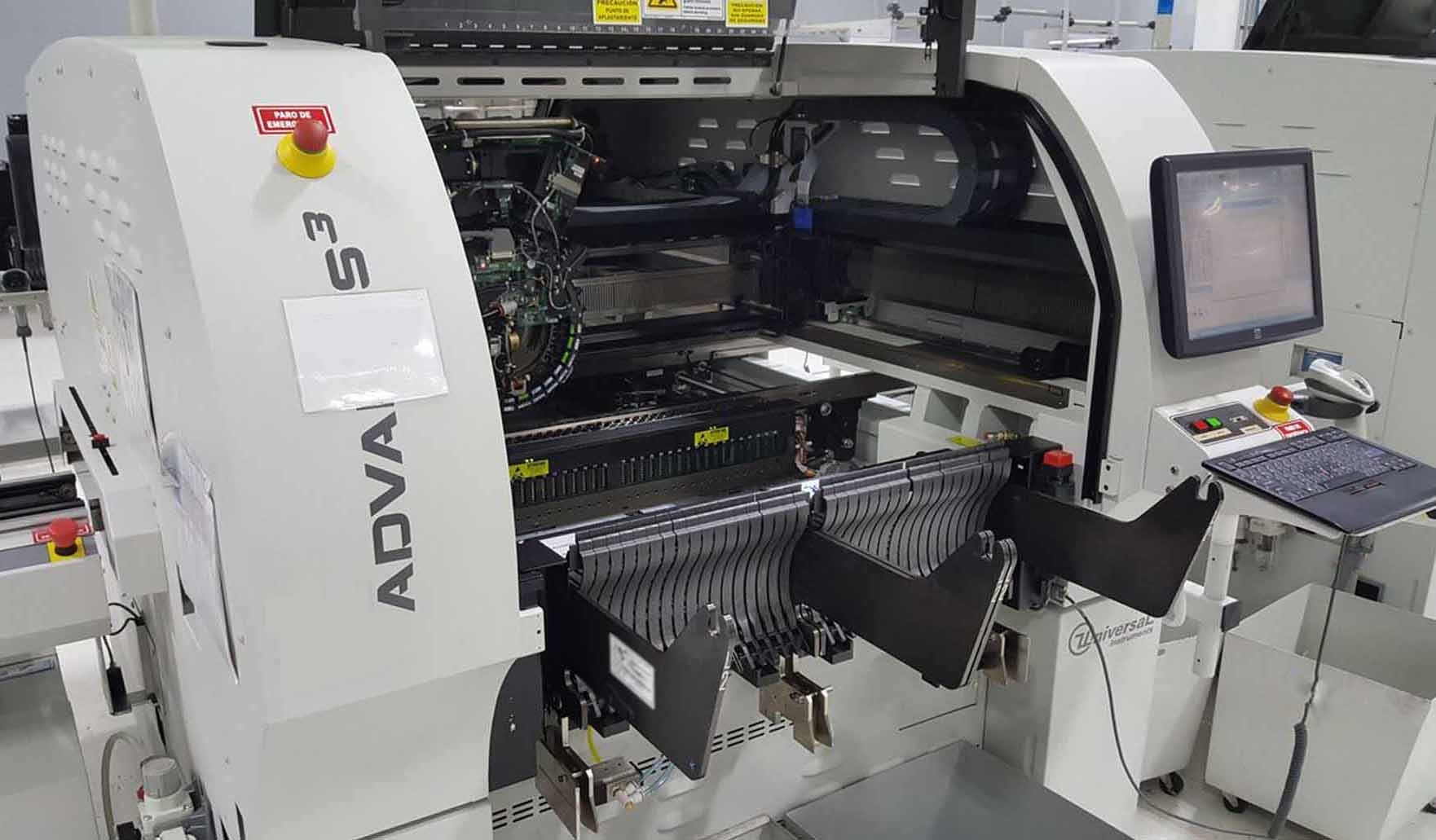

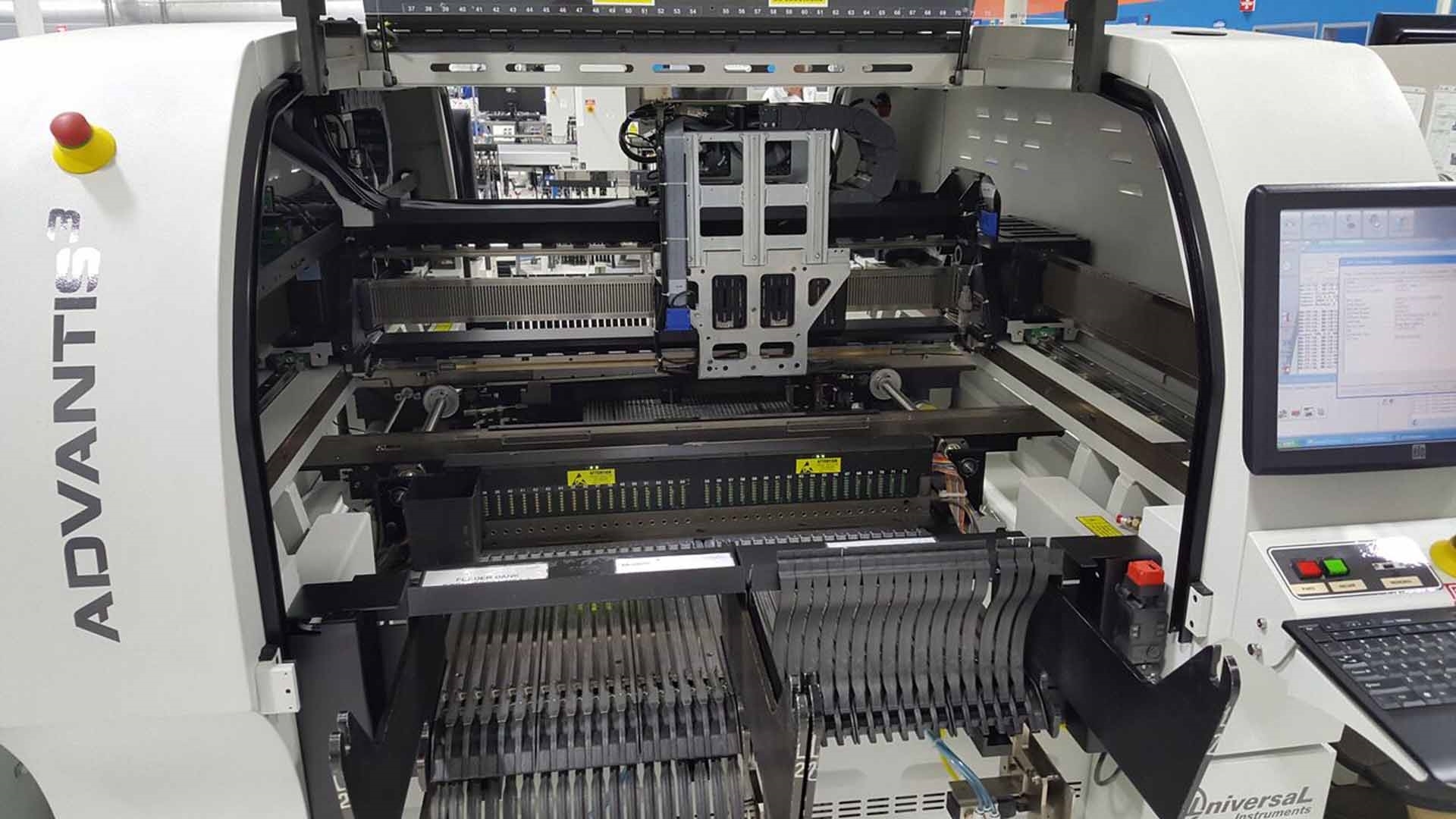

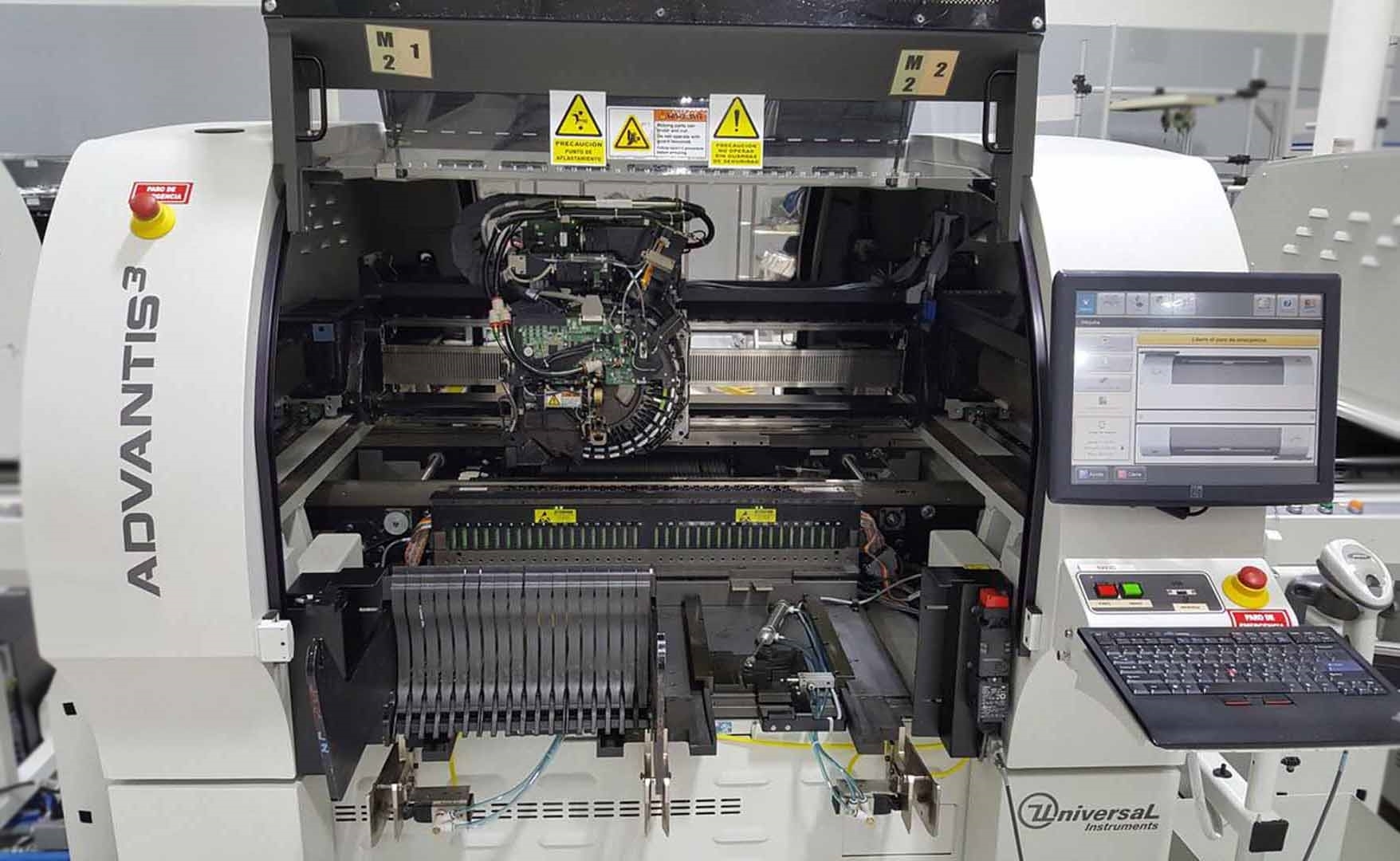

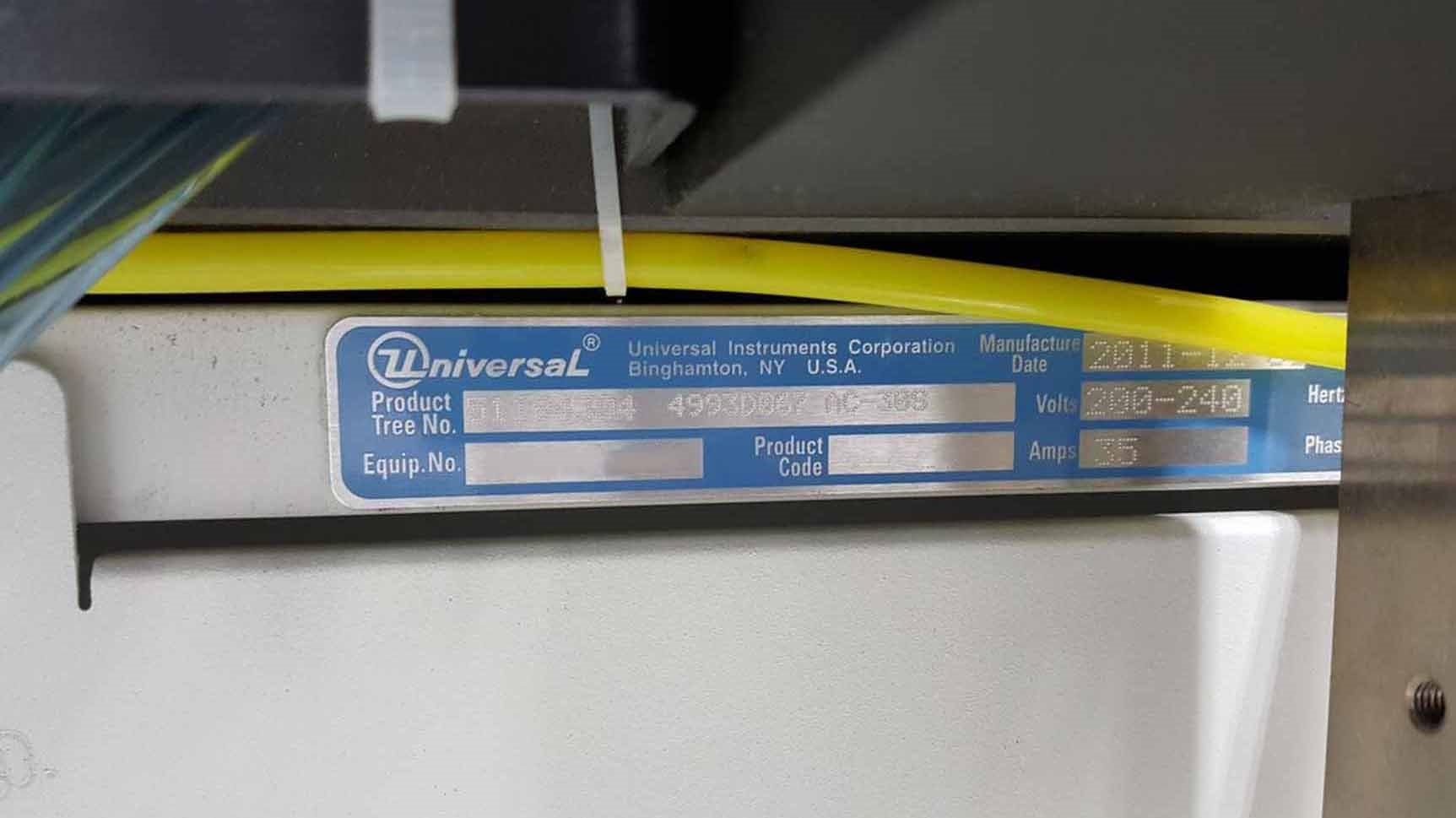

Used UNIVERSAL Advantis 3 AC-30S #9225821 for sale

URL successfully copied!

Tap to zoom

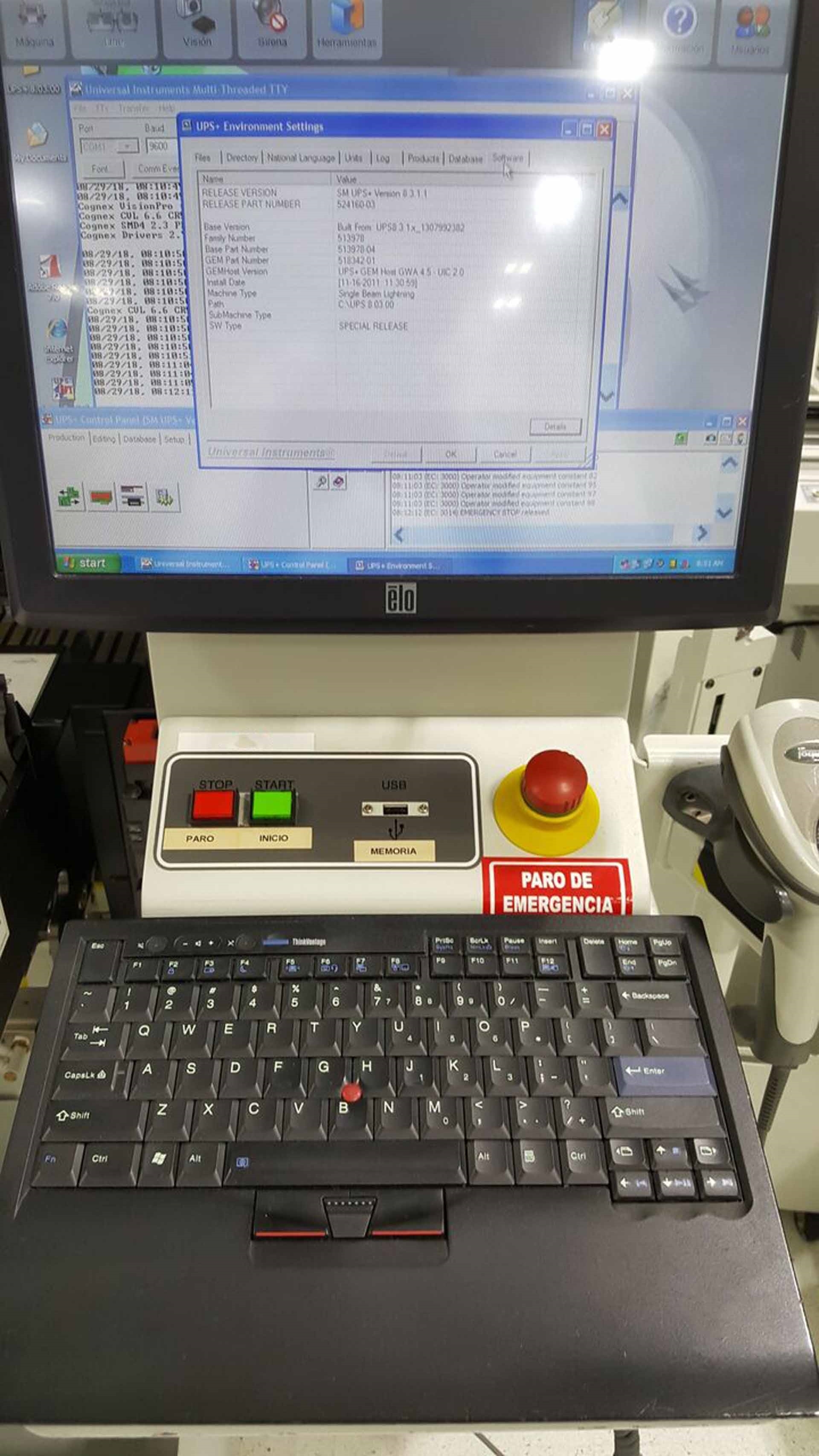

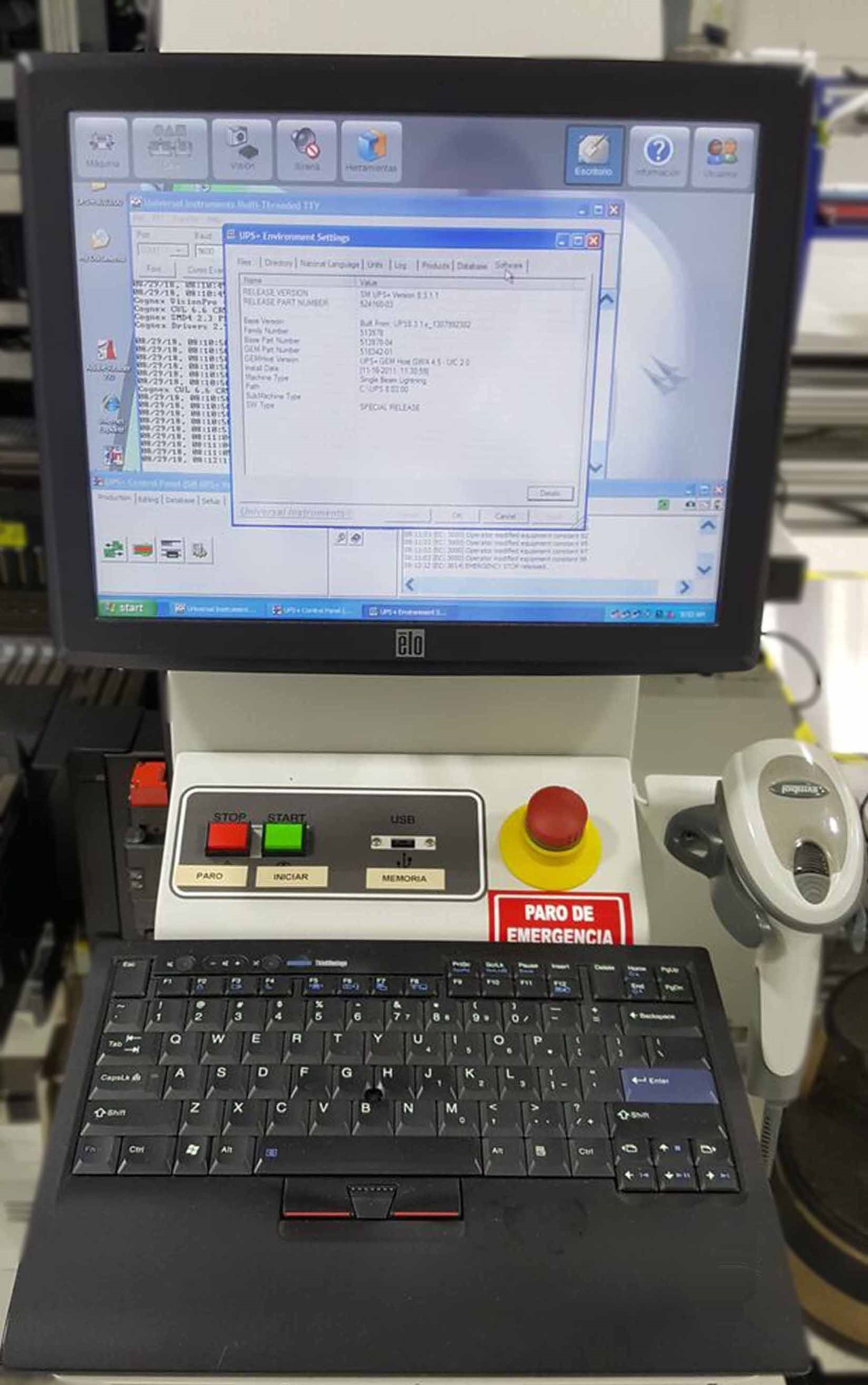

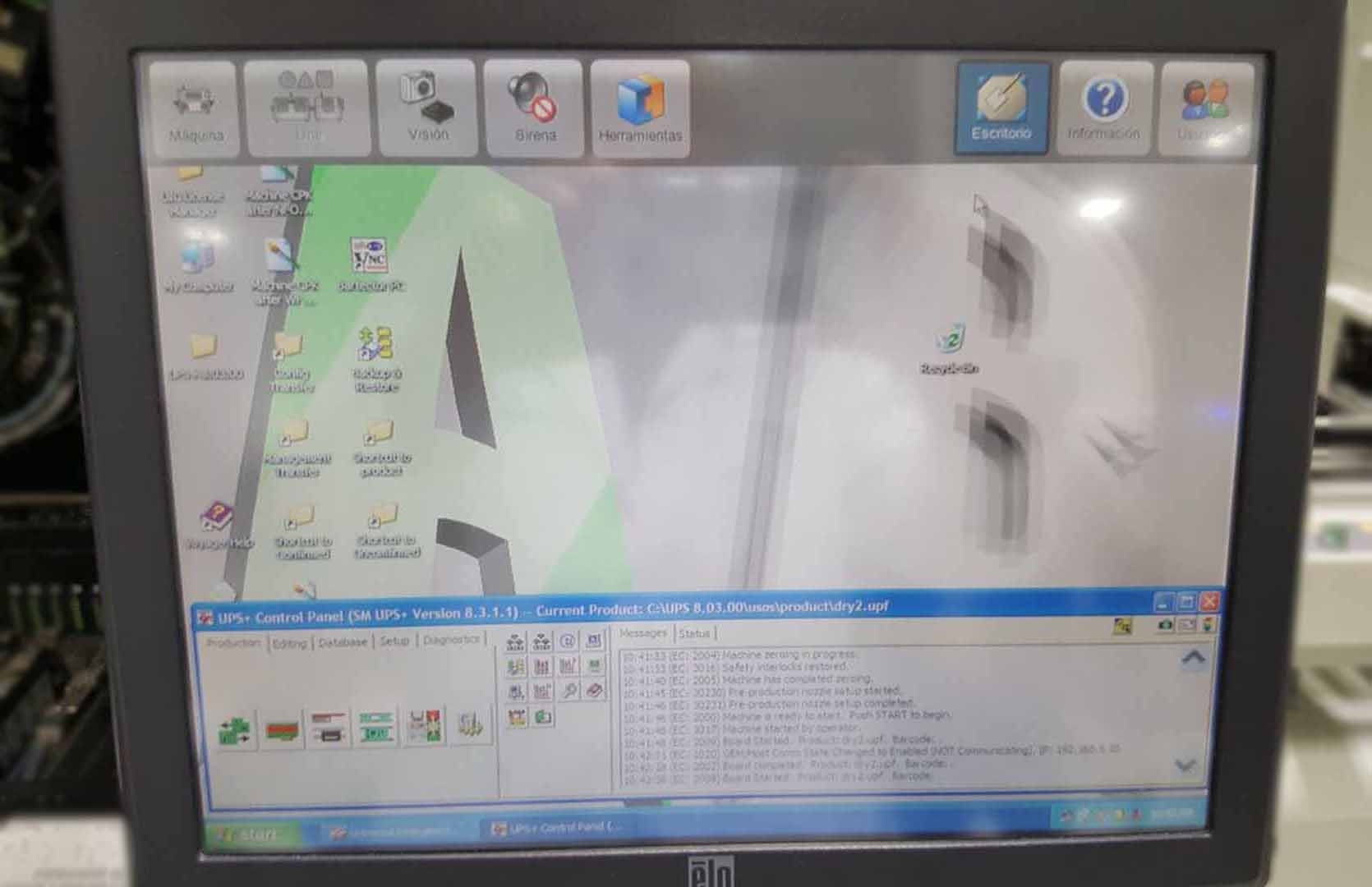

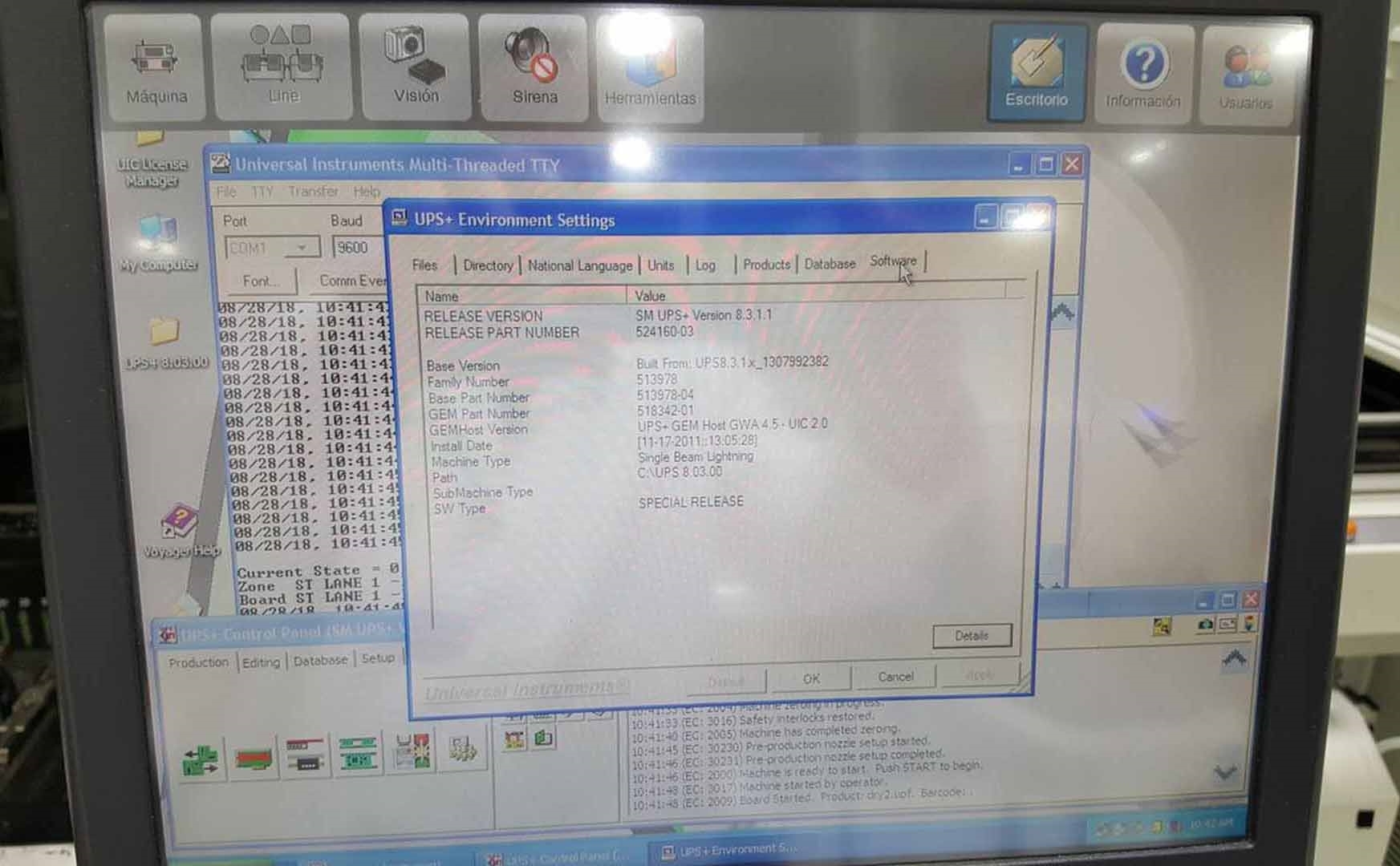

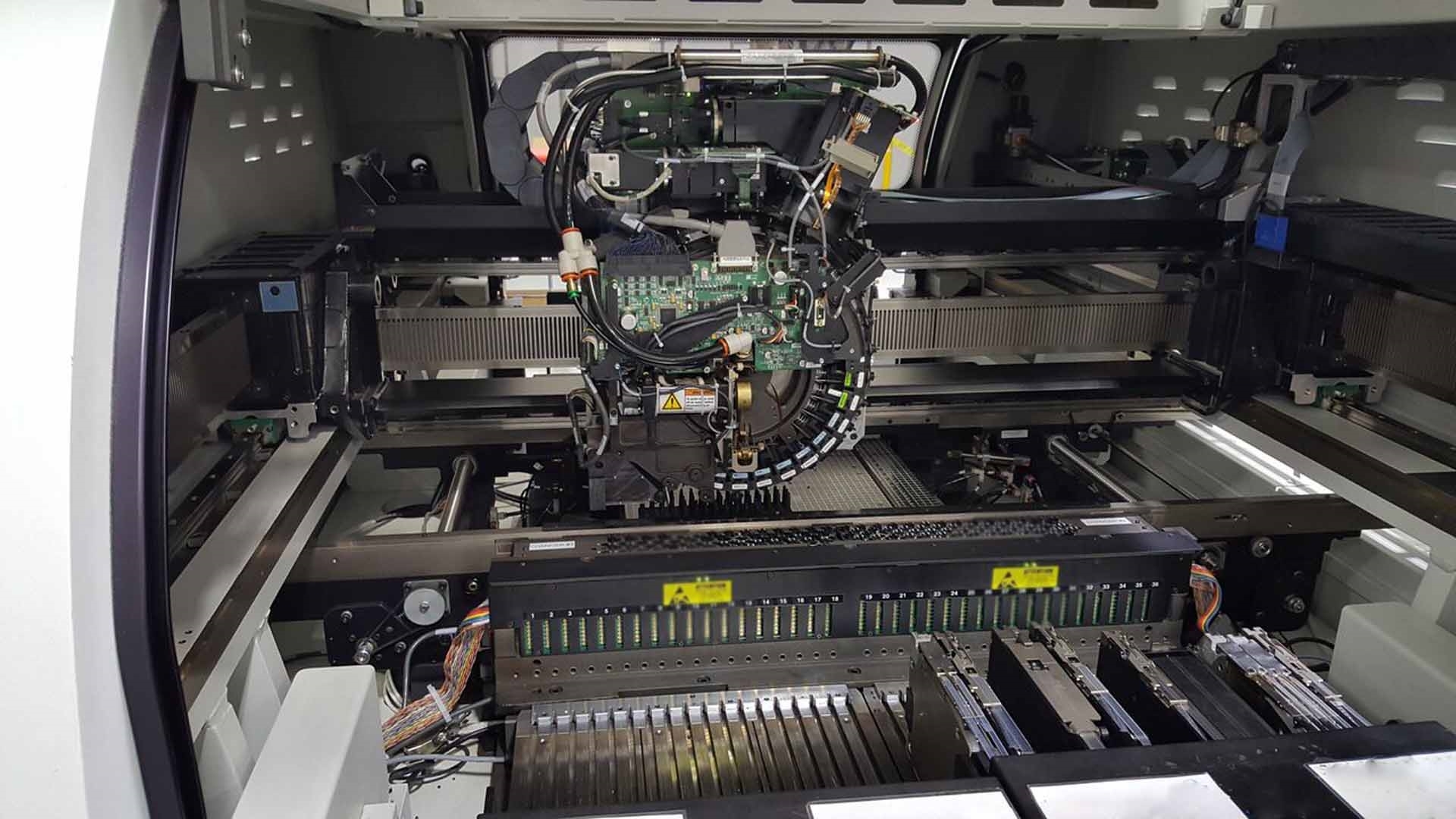

UNIVERSAL Advantis 3 AC-30S is a comprehensive pc board assembly and manufacturing equipment. It is designed to streamline and automate the entire assembly process, from start to finish, for maximum efficiency. The AC-30S is equipped with numerous features and capabilities designed to maximize production and reduce errors. The AC-30S uses an Opti-Flex conveyor system that provides a quickly adjustable track length that reduces setup time. By utilizing a modular design, the unit can easily be expanded to accommodate increased demand. The AC-30S is also equipped with 3D vision, which offers rapid inspection and capture of component images. In addition, the machine is capable of automatically changes and manages feeder parameters. The AC-30S is designed to run with a wide range of components, from zero to 153mm in size, with zero to one hundred eighty component pockets per panel. The tool is capable of supporting component form factors such as BGA, CSP, QFN, and other high-density IC packages. The fully automated process allows for F/J/L/TIP components, and nozzles that can be changed with no operator intervention. The AC-30S also includes a feature rich, full color user interface. This interface is available in different levels of software, which allows users to customize their asset to meet their specific needs. With the custom software package, the model can be set to recognize specific components, and will report on the exact location and quantity of each type of component used in the assembly process. The AC-30S also offers advanced area correction, which ensures that there is no contact failure or damage to the circuits or components. The equipment is capable of adjusting the area correction to account for different component sizes, board thickness, and component orientation. In addition, the AC-30S can automatically adjust to changes in temperature, humidity, and environmental conditions, which further improves the production process. Finally, the AC-30S is extremely reliable and accurate. The system provides repeatable accuracy to within +/- 5 mils, which helps to ensure that errors are minimized and productivity is maximized. In summary, Advantis 3 AC-30S is an all-in-one pc board assembly and manufacturing unit. It is packed with features to make the production process more efficient and reduce errors. Its Opti-Flex conveyor machine quickly adjusts to board sizes and component form factors. In addition, it's custom software allows users to customize the tool to meet their needs. The AC-30S is also extremely accurate and reliable, with a repeatable accuracy of within +/- 5 mils.

There are no reviews yet