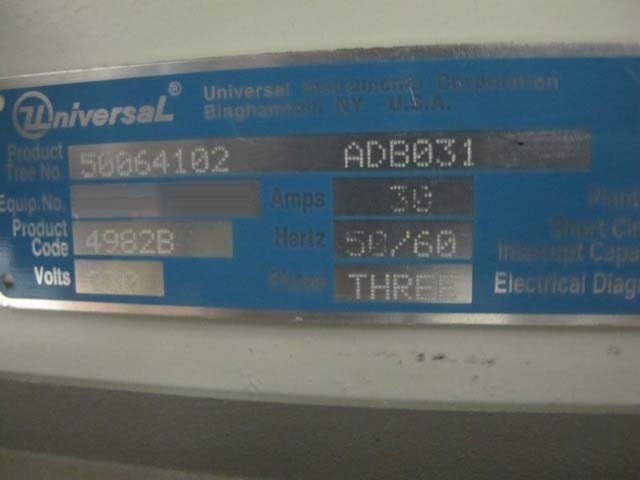

Used UNIVERSAL AdVantis 4982B #9302224 for sale

URL successfully copied!

Tap to zoom

ID: 9302224

Vintage: 2004

Pick and place system

Chip placement: 18,500 CPH / 0.19 sec (Per component)

Chip accuracy: ±60 µm at 3 Sigma

Feeder slots: Up to 144 unique components

Tape: 8 mm

Platform Tray Feeder (PTF)

Feeder types:

Tape (8 mm to 120 mm)

Tray

Tube

Bulk

Placement heads: (7) Spindles high speed

PCB Dimensions:

Length:

Minimum: 2"

Maximum: 20"

Width:

Minimum: 2"

Maximum: 14"

Thickness

Minimum: 0.02"

Maximum: 0.2"

Analog / Digital camera

Large board kit: 457.2 mm x 508 mm (18" x 20")

Matrix tray feeder:

Stackable

Stationary

Platform tray feeder

Offline feeder setup tool

Feeder bank change

Programmable Width Control (PWC)

Rear control interface

Board support

2004 vintage.

UNIVERSAL AdVantis 4982B is a highly sophisticated, PC board assembly and manufacturing equipment that offers a comprehensive set of features and factory-scale automation capabilities. It combines the advanced electronics assembly technology of AdVantis 4982B with an interactive PC-based user interface and intelligent vision-guided robotic systems for an unparalleled high-level production platform. The system offers advanced production technology in the form of a complex, open architecture that allows for comprehensive flexibility to meet various customer needs. The unit includes a fully-automated board assembly and screen printing capabilities, enabling fast and accurate board assembly processes. It also offers advanced reflow soldering processes and board-level autonomous optical inspection systems, which eliminate human labor while significantly reducing material costs. The assembly process is also aided by a SmartPC control machine and advanced robotic systems for improved production efficiency. The tool also takes advantage of smart materials such as passive components to reduce waste and improve quality. With 24-hour production capabilities, UNIVERSAL AdVantis 4982B is able to quickly respond to customer demands with higher quality and fewer production defects. AdVantis 4982B is also equipped with a distributed control asset that allows for greater scalability and flexibility. Each robotic unit has its own onboard CPU, allowing for efficient connection to additional hardware. This also enables a higher level of process monitoring and customization, allowing for flexibility and scalability should customers increase their product volumes. UNIVERSAL AdVantis 4982B uses intelligent vision-guided systems to improve the accuracy of the assembly process. The vision model integrates advanced optical and image recognition technologies to detect the presence of parts, detect shorts and check if each component is properly oriented. The equipment is also capable of automatically monitoring and controlling the manufacturing process, ensuring that all components are placed accurately and assembled properly and eliminating human errors. Finally, AdVantis 4982B is capable of integrating with other industry-standard software systems. This allows the system to connect to corporate databases of customer requirements, component libraries, inventory systems and company floor management tools, guaranteeing that production is tailored to meet customer needs with greater accuracy.

There are no reviews yet