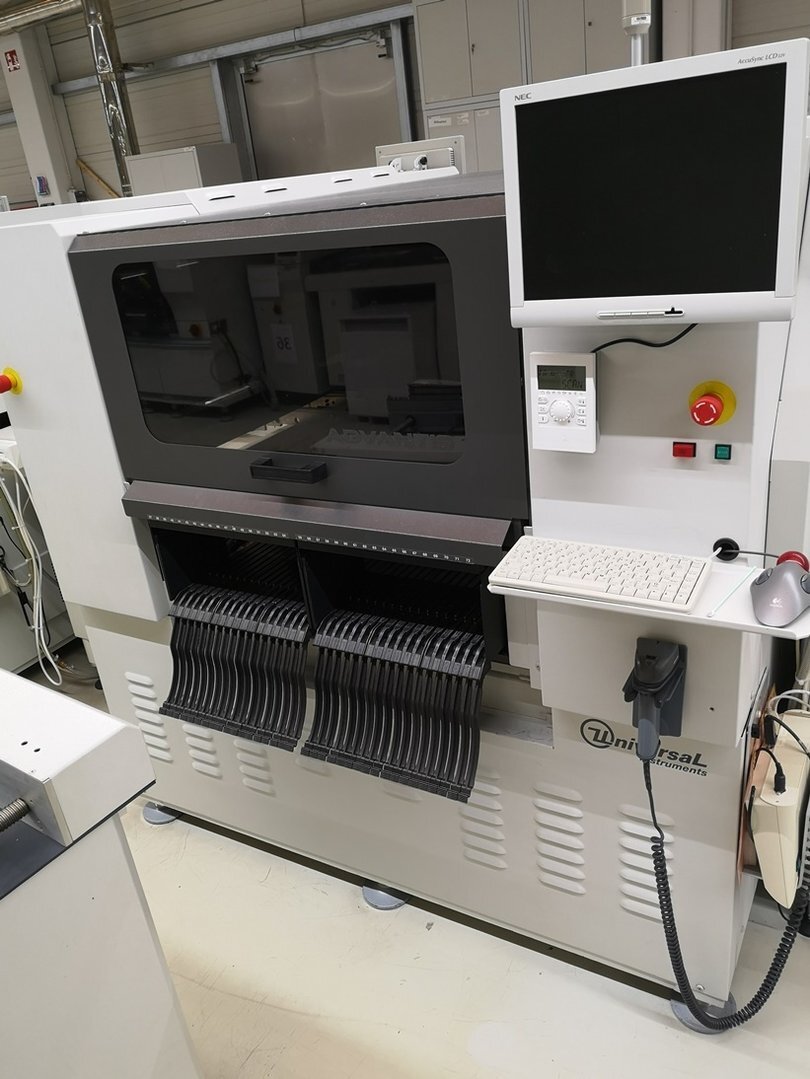

Used UNIVERSAL Advantis 4983A AC-30L #9302323 for sale

URL successfully copied!

Tap to zoom

ID: 9302323

Vintage: 2005

Pick and place machine

Conveyor: 1000 mm

PTF

2005 vintage.

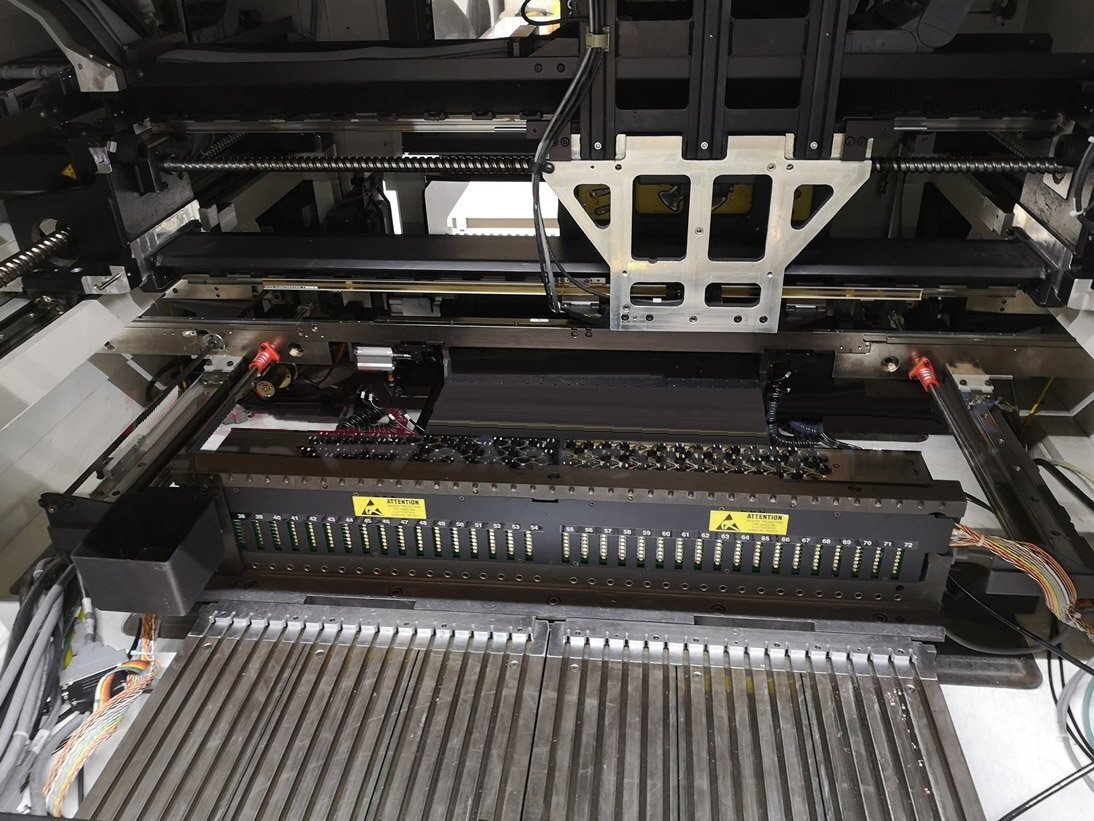

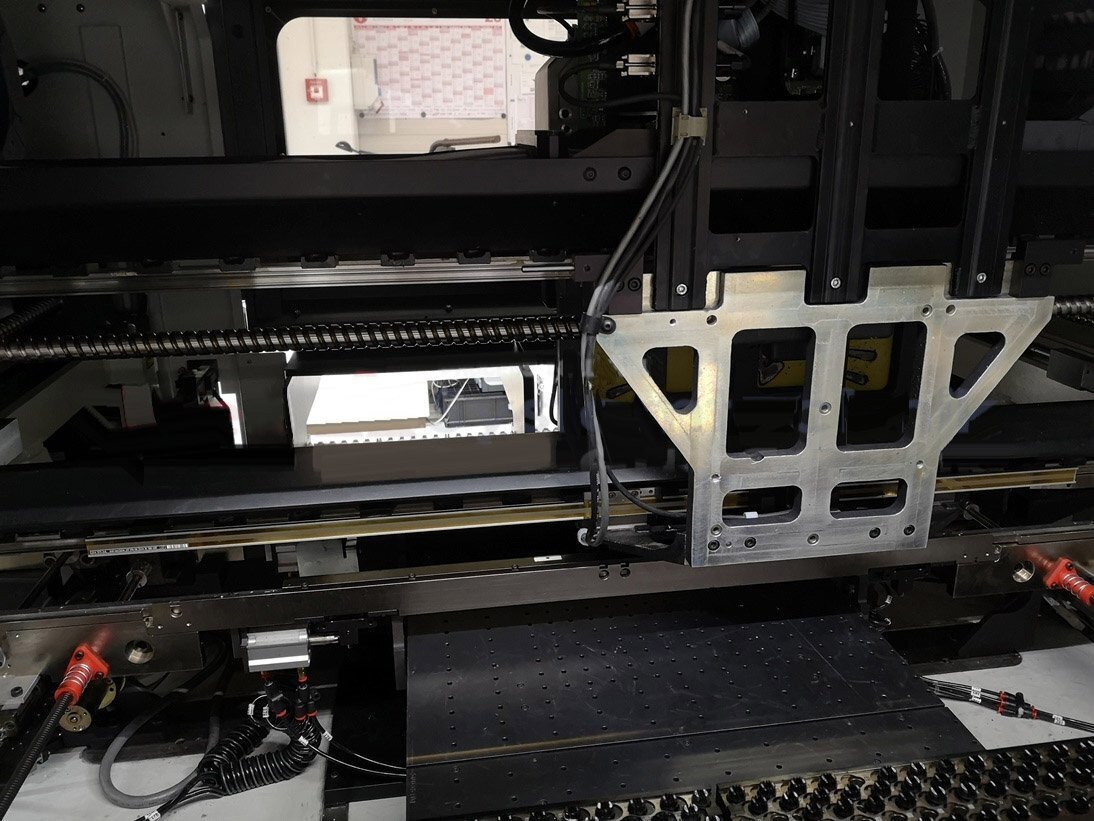

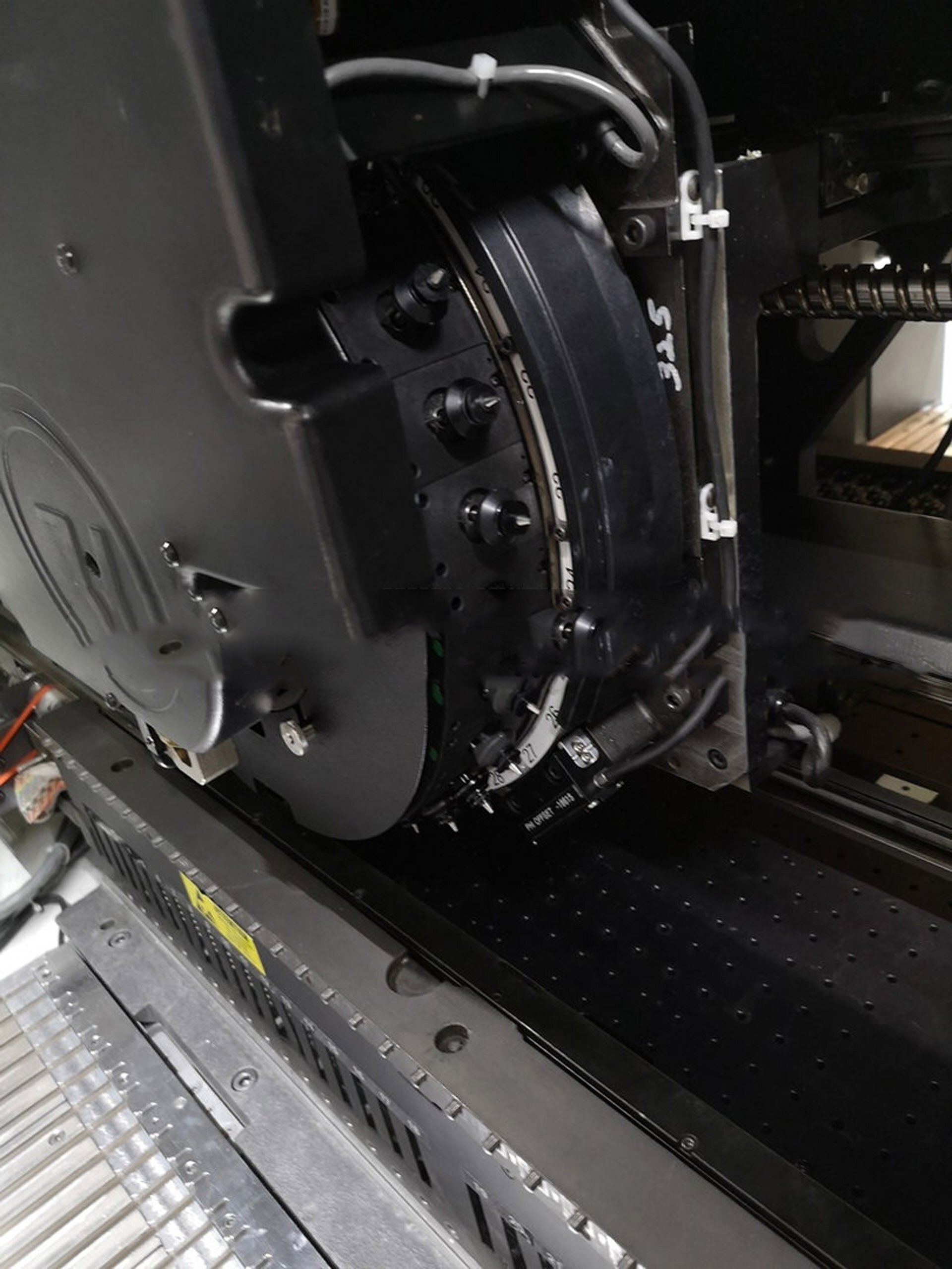

UNIVERSAL Advantis 4983A AC-30L pc board assembly and manufacturing equipment offers a unique and highly efficient means of producing electronic components. This system is designed to facilitate the rapid production of printed circuit boards and other related material. The unit features a 30-zone assembly, utilizing air gap technology and a fast-feed segment to expedite the production process. Advantis 4983A AC-30L features a 3-stage assembly and manufacturing machine. The first stage includes pre-treatment and application of the raw material. Secondly, the printed circuit boards are filled with electronic components through the use of a multi-downdriver assembly area. Finally, the automated inspection station culminates the process by using high-precision optics to check for accuracy, quality, and reliability. UNIVERSAL Advantis 4983A AC-30L also offers an impressive array of additional features. Automation software and hardware utilizes advanced algorithms to increase production speed and accuracy, providing the highest quality standards. Additionally, the machine is adaptable to many different board types and configurations. With up to eight layers of thickness and components, the machine has the capability to produce both simple and complex designs. Advantis 4983A AC-30L also features an inline conveyor tool that allows for continuous production of printed circuit boards. Additionally, the asset provides real-time feedback on parameters such as production time, components quality, outputs, and other performance indicators. The accompanying software also allows users to monitor, control and analyze production runs, providing the necessary data to optimize production processes. Overall, UNIVERSAL Advantis 4983A AC-30L pc board assembly and manufacturing model is an impressive piece of equipment that offers an efficient, reliable and cost-effective method of producing printed circuit boards and related material. Its advanced automation capabilities provide a secure, high-quality standard and allow users to produce complex designs with ease. The accompanying software also provides invaluable feedback and data, allowing users to optimize the production process.

There are no reviews yet