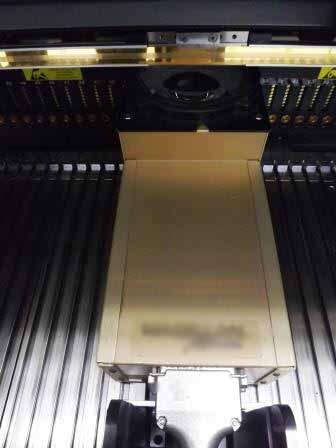

Used UNIVERSAL GENESIS GI-14 #9135654 for sale

URL successfully copied!

Tap to zoom

ID: 9135654

Vintage: 2004

Chip mounter,

Dual beam dual drive with two 7 spindle Flexjet 3 heads

On the head and upward looking digital cameras

Max speed: 30,000 cph

IPC Chips (1608) 22,400 cph

Component range 0201 -55 x 55mm svof

Maximum component height: 25mm

Feeder inputs: 120 - 144 (8mm tape)

Feeder types: tape, tray, tube, component strips, bowl, odd form, wafer, waifer and gel pack.

Max pcb size: 505 x 635 x 5mm

Min pcb size: 50,8 x 50,8 x 0,508mm

Max pcb weight: 2,72kg

Top side clearance: 26,5mm

2004 vintage.

UNIVERSAL GENESIS GI-14 is an automated printed circuit board (PCB) assembly and manufacturing equipment. It is designed to handle a wide range of PCBs, from small, intricate flex circuit boards to large, standard circuit boards. The GI-14 can accommodate any standard components, including single sided and double sided boards, as well as surface-mount and through-hole components. The system also supports UNIVERSAL and custom stackable PCBs. The unit features advanced programming capabilities, enabling the machine to integrate with other equipment and systems, as well as to customize its operations. The GI-14 is equipped with a highly advanced vision inspection machine, which can detect aesthetic defects in the components and assemblies, as well as the soldering joints. The machine also has an automated aerial inspection tool, which is capable of detecting minor deficiencies and manufacturing defects in finished products. The GI-14 has a high speed placement and precision manipulation asset, as well as an advanced pick-and-place model, both of which have maximum speed ratings of 1,000 cph. The equipment is also equipped with an auto-feeder unit, which is capable of feeding components to the head of the machine with minimal operator intervention. The system is equipped with a robotic arm, as well as motorized pick-and-place functions, enabling it to be utilized in various production scenarios. The GI-14 is equipped with multiple tool heads, allowing it to perform operations like drilling, milling, routing, probing and stamping, enabling it to be used for multiple types of PCB jobs. The unit's controllers are fully customizable, and the user is able to decide the type of tool to be used for each process, as well as the exact parameters for each operation. The machine is also equipped with a cabling unit, allowing it to cable multiple boards and components together. The GI-14 is an extremely accurate and reliable tool, and its advanced inspection capabilities, coupled with its wide range of capabilities, make it an invaluable asset for any PCB manufacturing facility. It is a true workhorse, with the capability to complete large and intricate PCB jobs with minimal operator intervention.

There are no reviews yet