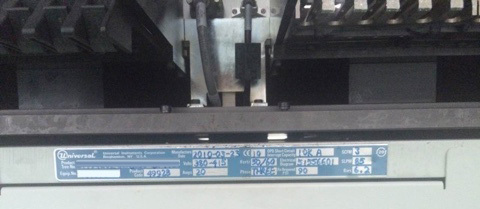

Used UNIVERSAL GENESIS GX-11S #9156858 for sale

URL successfully copied!

Tap to zoom

ID: 9156858

Vintage: 2010

Pick and place machine

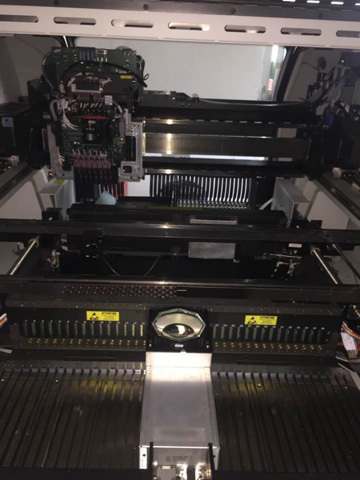

Single beam head

Flow: Left to Right

Camera resolution: 0.5 MP

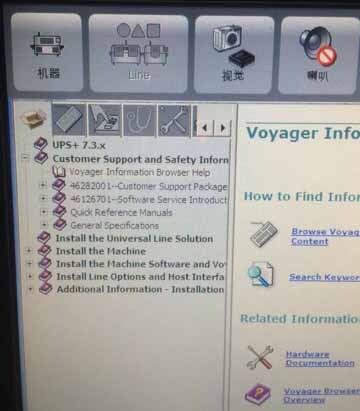

Software version: 7.1.2.3

Spindle head: InLine7 Head

Dual-head configuration

No feeders

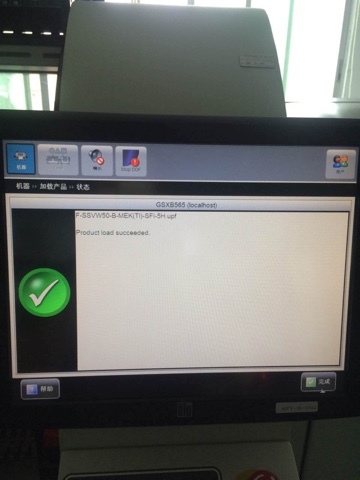

Currently installed

2010 vintage.

UNIVERSAL GENESIS GX-11S is a PC board assembly and manufacturing equipment that combines modern technology, such as surface mount technology and opto-pick and place machines, with higher-level features such as automated component identification, design-for-testability, and real-time component traceability. It also offers efficient line balancing and automated production line optimization, together with automated parts loading and feeder calibration - resulting in shorter, fully-integrated production lines. The system is built around a modular concept, allowing for the integration of a wide range of components and modules. This includes the GX-11S control unit, which provides the processor and memory, job programming, product programming, custom programming, input/output interface, and manufacturing and performance data management. There are also a variety of other modules available, such as surface mount, pick and place, SMT conveyors, and other component storage and loading systems, which allow for the full integration of the assembly process. The GX-11S can produce printed circuit boards (PCBs) with a high quality and in the shortest lead times. This is possible because of its advanced imaging and probing technology, combined with the smart, automated component identification unit. This allows for very accurate placement and probing, enabling the machine to work faster and more accurately than manual assembly. Additionally, the tool's real-time component traceability helps to ensure that no mistakes are made during the assembly process. The asset also offers automated line balancing and optimization. This enables the user to balance the production line, so that the production process flows efficiently. This allows for the optimization of overall model performance, while simultaneously controlling costs and ensuring high quality. Additionally, the equipment provides automated parts loading and feeder calibration, which can help to speed up the assembling process. This helps to promote better quality and reduces the number of mistakes. GENESIS GX-11S is a PC board assembly and manufacturing system that delivers a comprehensive package of features and capabilities. This unit is a cost-effective, reliable solution for the production and assembly of PCBs, offering high levels of accuracy and precision while providing shorter lead times. With its advanced features and capabilities, it makes the production process faster and more efficient, saving time and money.

There are no reviews yet