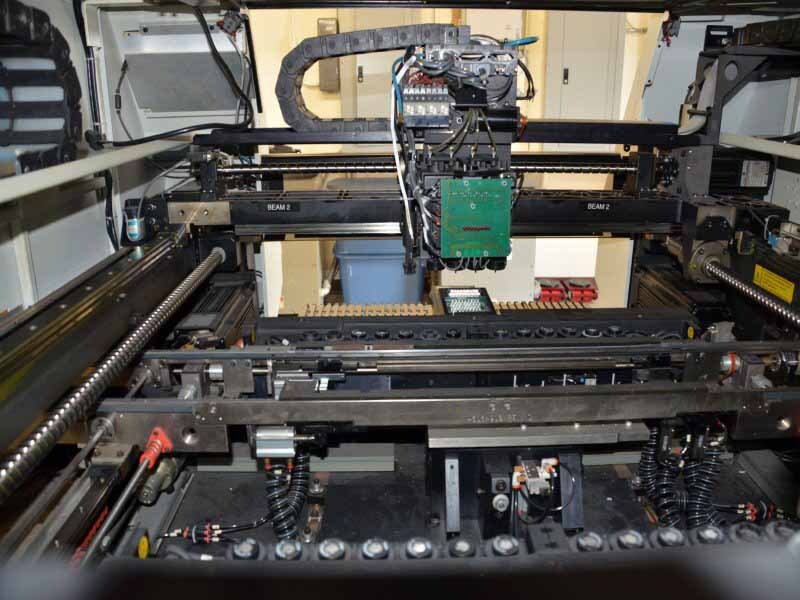

Used UNIVERSAL GSM 2 #9166487 for sale

URL successfully copied!

Tap to zoom

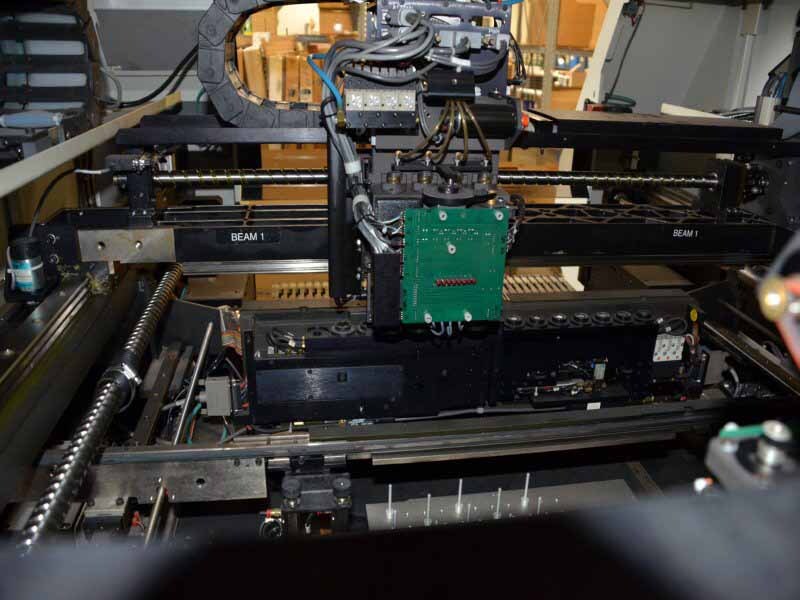

ID: 9166487

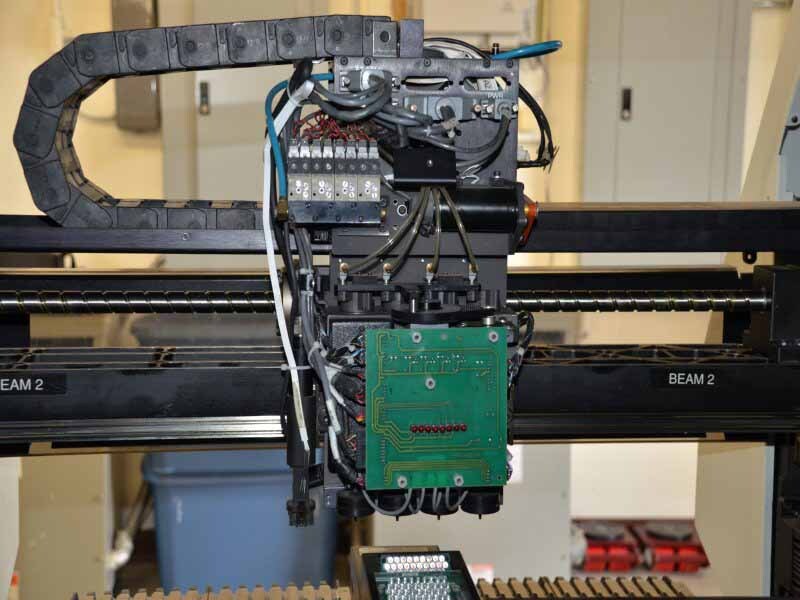

Pick and place machine

Fine pitch placement design

Precision linear scales

Brushless DC motors

On-the-fly vision system

CAD Translation

Machine performance simulator

Graphical interface

With an on-line component database

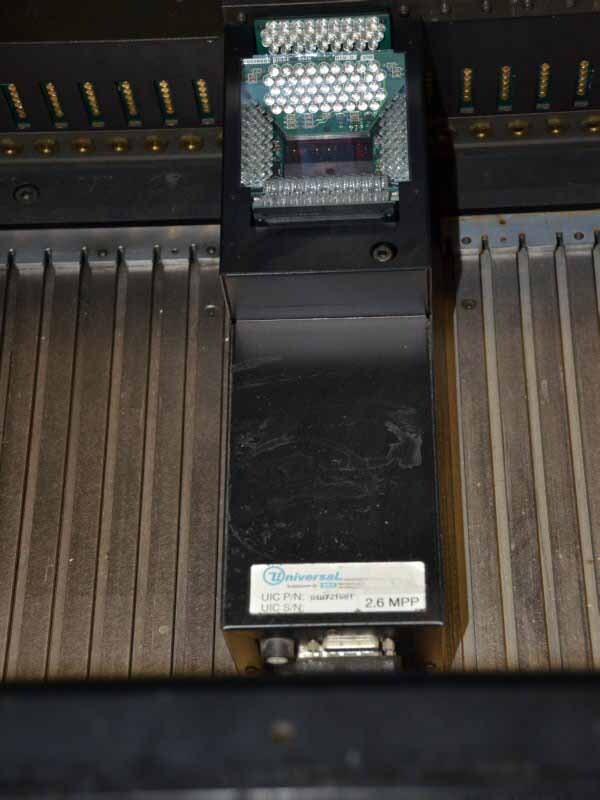

(2) Beams- (1) Placement head mounted in each beam

(4) Heads

Pneumatic requirements:

6 CFM @ 90 psi (113.3 l / min @ 6.22 bar)

Electrical requirements:

230 VAC Nominal

50 / 60 Hz, 3 Phase

30 Amps

Placement rate:

Test board rated: 10,000 Components per hour

Positioning system:

X Axis travel: 28.640 in (727.46 mm)

Y Axis front beam travel: 28.375 in (720.73 mm)

Y Axis rear beam travel: 30.000 in (762.00 mm)

Includes:

Feeder storage cart

(50) Assorted size GSM feeders

(39) 4mm x 8mm

(1) 8mm x 8mm

(4) 12mm

(6) 16mm x 4 to 58mm adjustable

Feeder cart: 36” x 37” x 65”

Document navigator platform for 46XX series GSM2 units

1995 vintage.

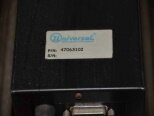

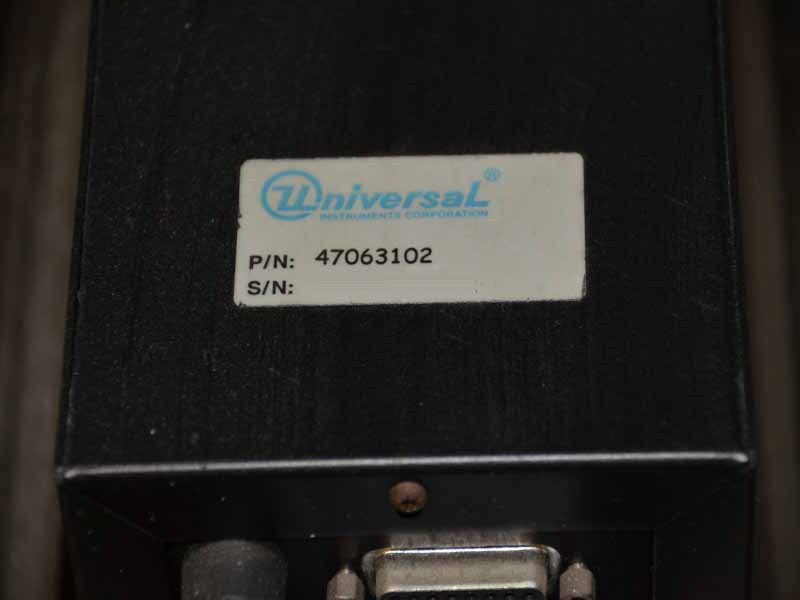

UNIVERSAL GSM 2 is a PC board assembly and manufacturing equipment from UNIVERSAL Instruments Corporation. It is a high-precision, automated production line designed to help companies reduce defects and ensure the highest quality boards. The system includes a range of machines such as GSM Selective Solder Machine, GSM Pick & Place Machine, GSM Dispensing Unit, and GSM AOI inspection machine. In addition, the tool also features several automated quality control processes to ensure product integrity. The GSM Selective Solder Machine provides an automatic, fully programmable process for solder joints. It streamlines production and eliminates manual processes, such as manually soldering components. The GSM Pick & Place Machine is an automated robotic arm used to place components onto PCBs with great accuracy and speed. The GSM Dispensing Asset uses an on-board computer to accurately and quickly deposit glue and die attach materials into precisely defined areas of the boards. Finally, the GSM AOI (Automated Optical Inspection) model probes the boards for quality assurance, ensuring that all components are placed correctly and securely. The entire equipment is highly customizable and can be easily adapted to meet production needs. It also has an intuitive user interface and manual entry options to ensure that operators can quickly and accurately populate boards. This automated system is designed to reduce production time and increase quality and efficiency. In addition, UNIVERSAL GSM2 is equipped with a range of additional features to ensure safety and efficiency. It has a range of connection options such as GPRS, WiFi, and Bluetooth for easy connectivity and integration. It also includes advanced process and monitoring tools for real-time performance analysis and quality assurance. Finally, the unit is built around the company's Pro-Tech machine, providing customers with comprehensive warranty and technical support. In summary, GSM 2 is a comprehensive PC board assembly and manufacturing tool from UNIVERSAL Instruments Corporation. It is designed to provide high-precision, automated production lines with programmable processes and comprehensive quality control systems. The innovative asset also has an intuitive user interface and advanced process and monitoring tools to provide customers with the highest level of safety and efficiency.

There are no reviews yet